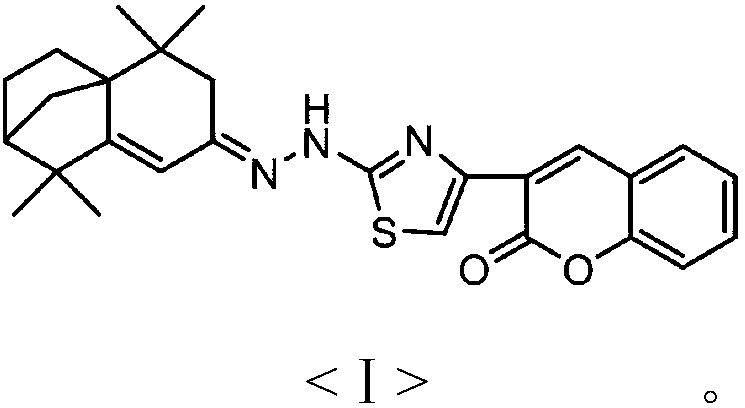

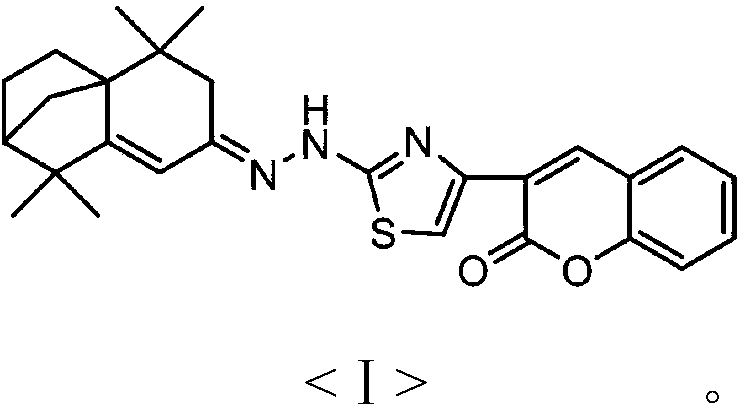

Steel rust inhibitor and preparation method and application thereof

A rust inhibitor and steel technology, which is applied in the field of steel rust resistance, can solve the problems of anti-corrosion performance indicators such as zero pollutant discharge and mass discharge, which cannot be taken into account, and achieve excellent rust resistance performance, simple preparation process, and long-term effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

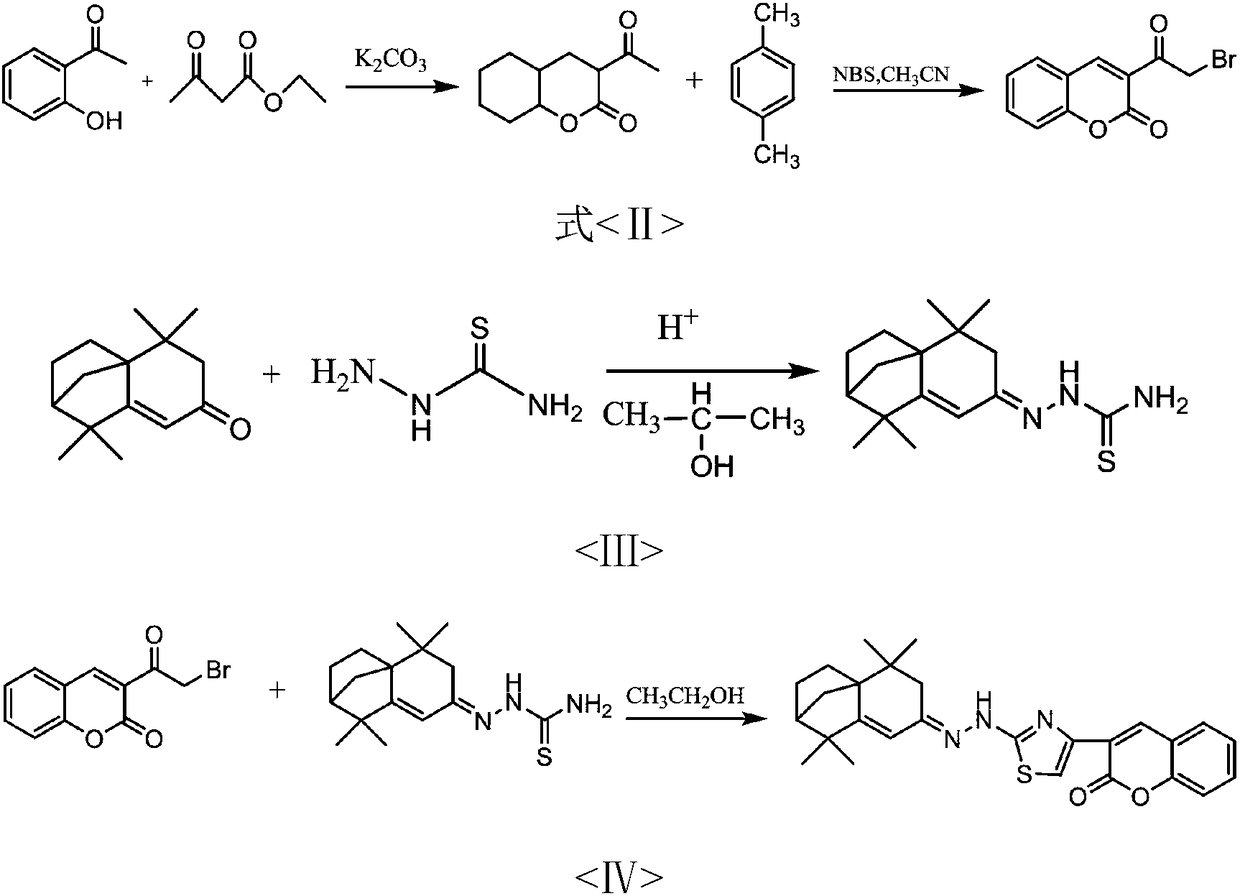

Method used

Image

Examples

Embodiment 1

[0024] Conditions: The experimental material is carbon steel (Fe: 99.5%, Mn: 0.4-0.5%, C: 0.1-0.2%), and the effective rust inhibitor is 2-isolongifolene hydrazino-4-(2-oxo Substituent-2H-benzopyran-3-yl)thiazole, the medium is 3.5% sodium chloride solution, add 2-isolongifolenonehydrazino-4-(2-oxo-2H-benzopyran- The effective content of 3-yl)thiazole is 1 mmol / L, the temperature is 25°C, and the pH=12.5.

[0025] The antirust efficiency obtained by the experimental test is 81.58% in the electrochemical impedance spectrum and 90.36% in the dynamic potential polarization curve, indicating that the compound is a rust inhibitor with low dosage and high efficiency.

Embodiment 2

[0027] Conditions: The experimental material is carbon steel (Fe: 99.5%, Mn: 0.4-0.5%, C: 0.1-0.2%), and the effective rust inhibitor is 2-isolongifolene hydrazino-4-(2-oxo Substitute-2H-benzopyran-3-yl)thiazole, the medium is 3.5% sodium chloride solution, add (2-isolongifolene hydrazino-4-(2-oxo-2H-benzopyran The effective content of -3-yl)thiazole is 0.5mmol / L, the temperature is 25°C, and the pH=12.5.

[0028] The antirust efficiency obtained by the experimental test is 85.79% in electrochemical impedance spectrum and 90.54% in dynamic potential polarization curve, indicating that the compound is a rust inhibitor with low dosage and high efficiency.

Embodiment 3

[0030] Conditions: The experimental material is carbon steel (Fe: 99.5%, Mn: 0.4-0.5%, C: 0.1-0.2%), and the effective rust inhibitor is 2-isolongifolene hydrazino-4-(2-oxo Substituent-2H-benzopyran-3-yl)thiazole, the medium is 3.5% sodium chloride solution, add 2-isolongifolenonehydrazino-4-(2-oxo-2H-benzopyran- The effective content of 3-yl)thiazole is 0.1mmol / L, the temperature is 25°C, and the pH=12.5.

[0031] The antirust efficiency obtained by the experimental test is 88.02% in electrochemical impedance spectrum and 91.74% in dynamic potential polarization curve, indicating that the compound is a rust inhibitor with low dosage and high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com