Magnetic separator

A magnetic separator and magnetic technology, applied in the direction of magnetic separation, chemical instruments and methods, classification, etc., can solve the problems of inability to separate shapes and residual rectangular particles, and achieve the effect of promoting shape separation and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

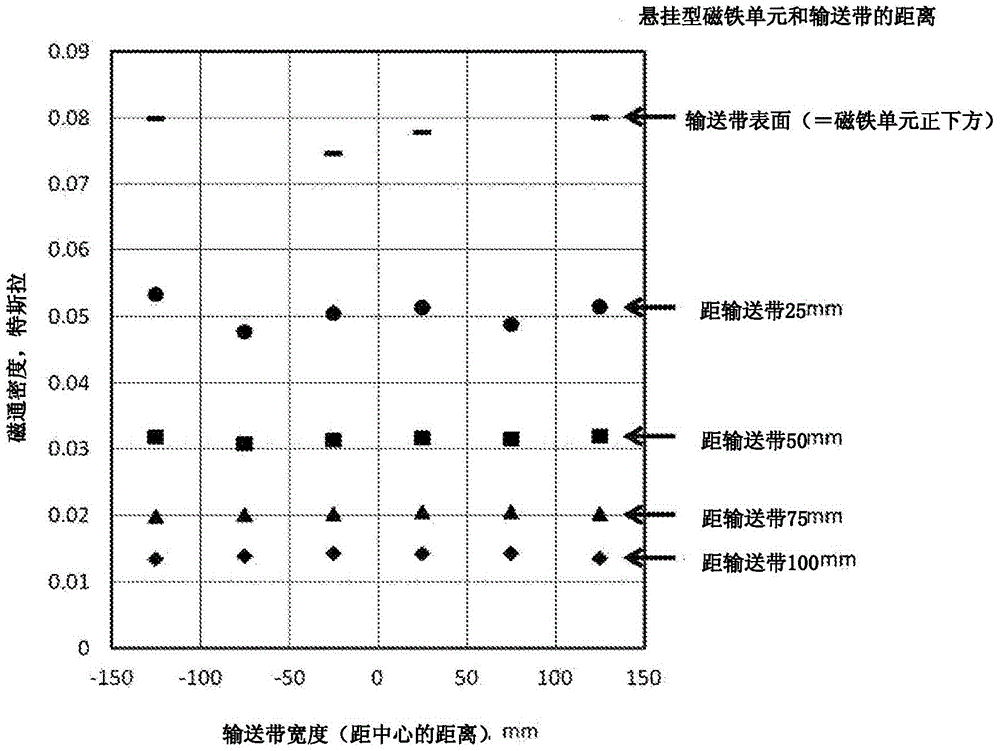

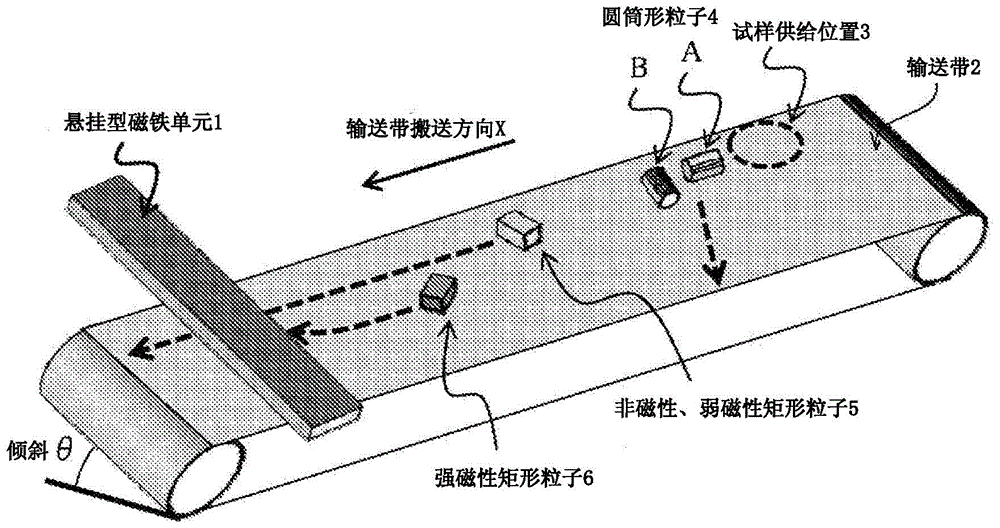

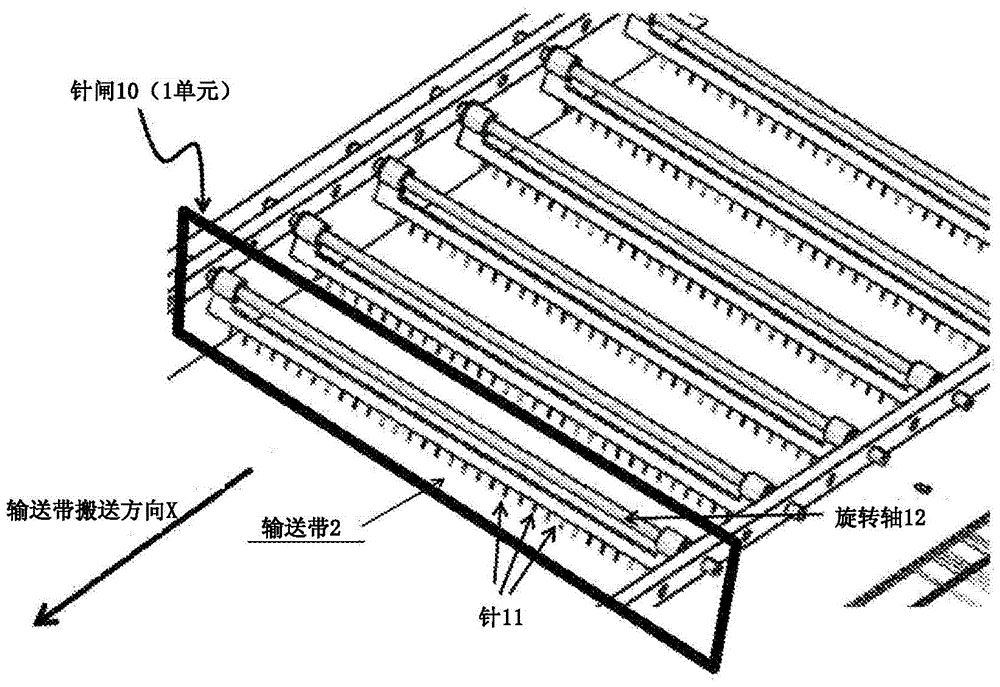

[0032] The present invention provides a weak magnetic force magnetic separator, which has: a belt conveyor, which transports the particles to be sorted; The sorted particles conveyed on the low-magnetic force magnetic conveyor belt are magnetically recovered for all strong magnetic substances, and no weak magnetic substances are recovered at all. It is characterized in that the suspension type magnet unit is set in the following way: the length direction The length of the magnet unit is greater than the width of the conveyor belt, so that the length direction of the magnet unit is consistent with the width direction of the conveyor belt, and the two ends of the magnet unit are more protruding than the width of the conveyor belt, and the distance from the surface of the conveyor belt becomes a fixed distance throughout the length direction. , in the range of weak magnetic force exceeding 0 and less than 700 gauss, the deviation of the magnetic flux density in the width direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com