Application of heterocyclic alcohol high-efficiency corrosion inhibitor for cupper in seawater

A technology of corrosion inhibitors and alcohols, applied in the field of heterocyclic alcohol corrosion inhibitors, can solve the problems of scarcity of corrosion inhibitors, poor activity, corrosion damage and other problems, and achieve the effect of convenient purchase, low cost and inhibition of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

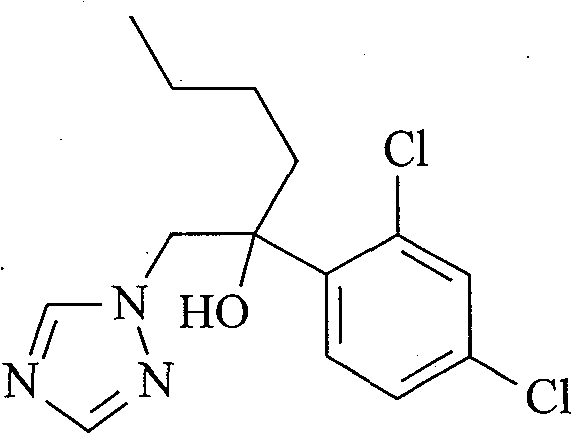

Image

Examples

Embodiment 1

[0017] Conditions: the experimental material is red copper (99.999%), hexaconazole and emulsifier are formulated into microemulsion, the medium is 3.5% sodium chloride solution, the dosage is 100L, the effective content of hexaconazole is 0.05g, and the temperature is 25°C. pH=7.5, immersion time is 20 days.

[0018] The corrosion inhibition efficiency obtained through the test is: weight loss 86.9%, electrochemical impedance spectrum 86.7%, dynamic potential polarization 91.2%, showing that it is a corrosion inhibitor with low dosage and high efficiency.

Embodiment 2

[0020] Conditions: The experimental material is red copper (99.999%), hexaconazole and emulsifier are formulated into microemulsion, the medium is 3.5% sodium chloride solution, the dosage is 100L, the effective content of hexaconazole is 0.06g, and the temperature is 25°C. pH=7.5, immersion time is 20 days.

[0021] The corrosion inhibition efficiencies obtained through experimental tests are: weight loss 91.2%, electrochemical impedance spectroscopy 90.6%, and dynamic potential polarization 92.8%, showing that it is a corrosion inhibitor with low dosage and high efficiency.

Embodiment 3

[0023] Conditions: the experimental material is red copper (99.999%), hexaconazole and emulsifier are formulated into microemulsion, the medium is 3.5% sodium chloride solution, the dosage is 100L, the effective content of hexaconazole is 0.08g, and the temperature is 25°C. pH=7.5, immersion time is 20 days.

[0024] The corrosion inhibition efficiencies obtained through experiments are: weight loss 93.4%, electrochemical impedance spectroscopy 93.8%, and potentiodynamic polarization 95.4%, showing that it is a corrosion inhibitor with low dosage and high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com