Brake system with magnetic rail brake

一种磁轨制动、制动设备的技术,应用在制动元件与轨道相互作用的制动器、制动器、铁道车辆制动器的操作机构等方向,能够解决磨损、磁轨制动装置不显著等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

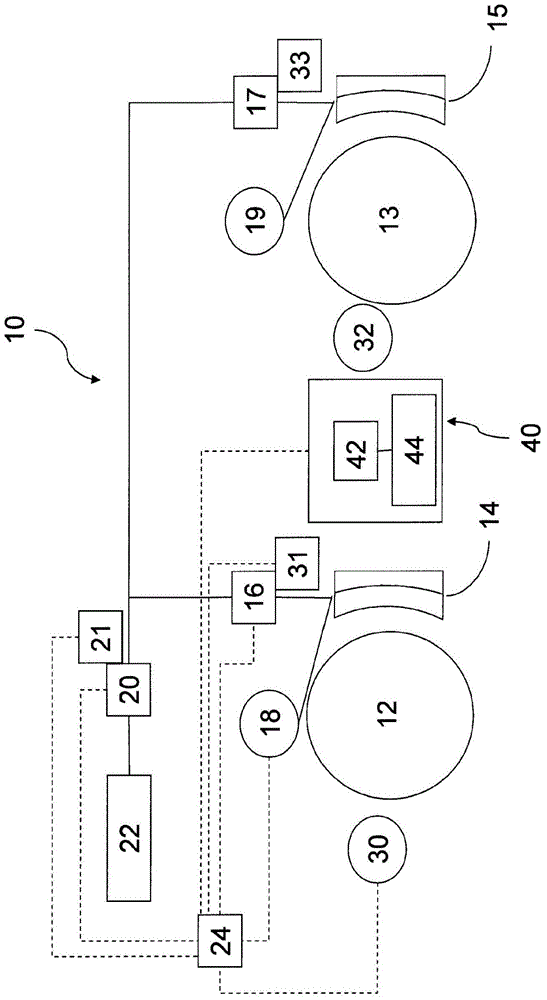

[0019] figure 1 A schematic diagram of a braking system 10 of a rail vehicle with a pneumatic service brake is shown. Mechanical and pneumatic connections and lines are shown in solid lines, while electrical connections or communication channels are shown in dashed lines. The braking system 10 is provided for braking wheels 12 and 13 of a rail vehicle. In this example, the wheels 12 and 13 are located on different axles, but on one bogie. A first brake shoe 14 is associated with the first wheel 12 . A second brake shoe 15 is associated with the second wheel 13 . Each brake shoe 14 , 15 has a brake shoe braking surface, which brakes the associated wheel when the brake shoe is pressed against the sliding surface of the associated wheel 12 , 13 by means of the brake shoe surface. The brake shoe 14 can be actuated for braking by means of a force generator 16 . The force generator 16 is connected via a power supply line to the main control valve arrangement 20 . Compressed ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com