Rust-resistant agent for concrete reinforcing bar and preparation method thereof

A technology of concrete steel bars and rust inhibitors, which is applied in the field of concrete steel bar rust inhibitors containing vapor phase corrosion inhibitors and its preparation, can solve the problems of anti-rust performance and diffusion performance of rust inhibitors, and achieve excellent anti-rust effects , good migration and diffusion properties, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

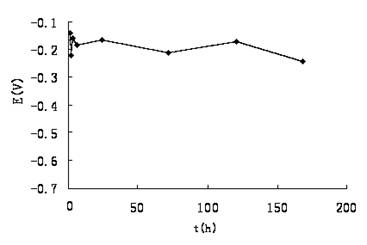

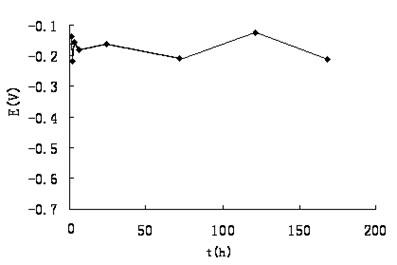

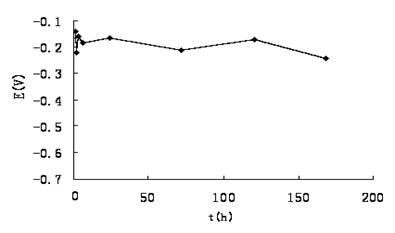

Image

Examples

Embodiment 1

[0031] Weigh 14g of adipic acid in a 1000 mL beaker, add 20 mL of deionized water, slowly add 20 g of cyclohexylamine under stirring at room temperature, (the molar ratio of dibasic acid, organic amine and water is as follows: dibasic acid: Organic amine: water (1:2.1:11.6) until the reaction is complete, the solution becomes transparent and clear, then heated and concentrated until an insoluble film appears on the surface of the solution, cooled to room temperature, and filtered to obtain 28g of the solid, which is gas phase corrosion inhibitor 1.

[0032] Weigh 16g (22.0%) of vapor phase corrosion inhibitor 1, 4g (5.5%) of sodium monofluorophosphate and 3g (4.1%) of calcium gluconate in 50mL of deionized water, stir, and adjust the pH to 7~8 with ethanolamine, namely Get steel bar rust inhibitor 1.

Embodiment 2

[0034] Weigh 10g of azelaic acid in a 1000mL beaker, add 15mL of deionized water, slowly add 10g of morpholine under stirring at room temperature, (the molar ratio of dibasic acid, organic amine and water is dibasic acid:organic amine:water 1:2.1:15.7) until the reaction is complete, the solution becomes transparent and clear, then heated and concentrated until an insoluble film appears on the surface of the solution, cooled to room temperature, and filtered to obtain 17g of the solid, which is gas phase corrosion inhibitor 2.

[0035] Weigh 15g (21.1%) gas-phase corrosion inhibitor, 2.4g (5.6%) sodium monofluorophosphate and 2g (2.8%) calcium gluconate, dissolve in 50mL deionized water, stir well, and adjust the pH to 7~8 with ethanolamine, that is Get steel bar rust inhibitor 2.

Embodiment 3

[0037] Weigh 15g of sebacic acid in a 1000 mL beaker, add 20 mL of deionized water, slowly add 10g of ethanolamine under stirring at room temperature, (the molar ratio of dibasic acid, organic amine and water is dibasic acid:organic amine: Water (1:2.2:15) until the reaction is complete, the solution becomes transparent and clear, then heated and concentrated until an insoluble film appears on the surface of the solution, cooled to room temperature, and 22g of the solid is filtered, which is the gas phase corrosion inhibitor 3.

[0038] Weigh 20g (26.3%) gas phase corrosion inhibitor, 3.4g (5.3%) sodium monofluorophosphate and 2g (2.6%) calcium gluconate, dissolve in 50 mL deionized water, add, stir, adjust pH to 7~8 with ethanolamine , that is, steel rust inhibitor 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com