Environment-friendly composite steel bar corrosion inhibitor for marine environment and preparation method of corrosion inhibitor

A composite steel bar and marine environment technology, applied in the field of material science and engineering, can solve the problems of large amount of single molybdate and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

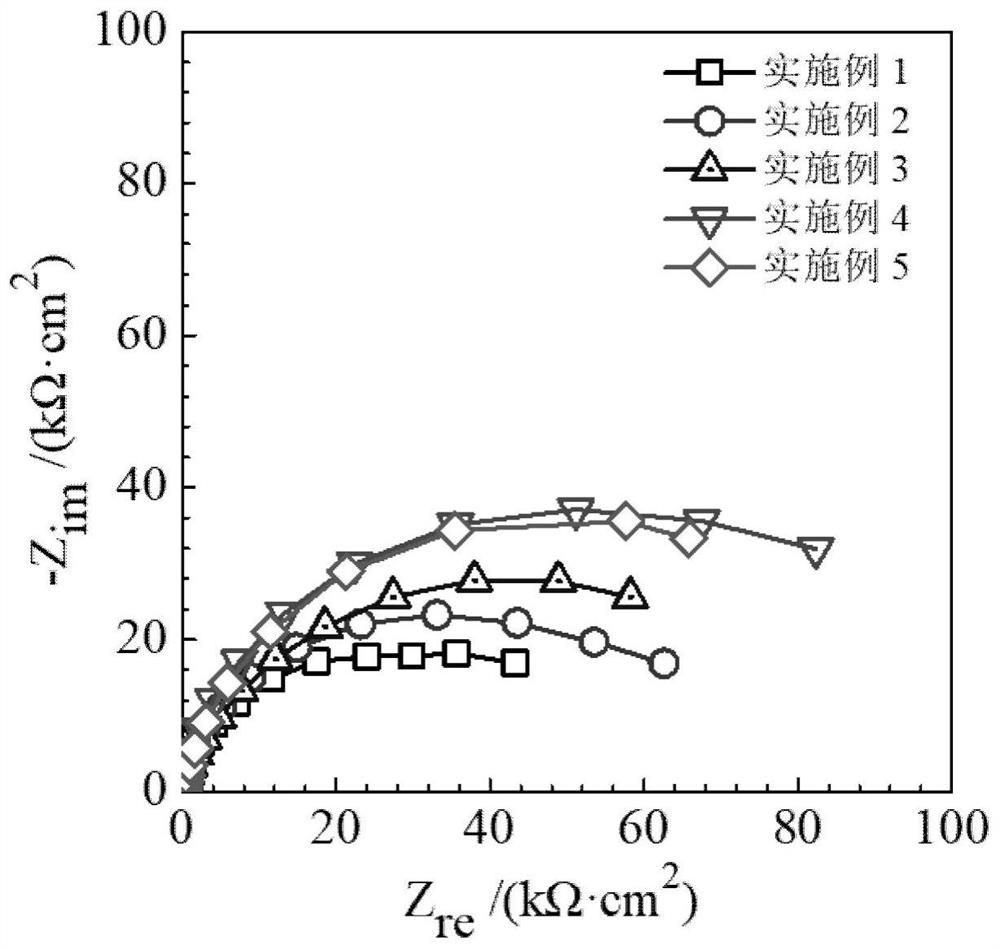

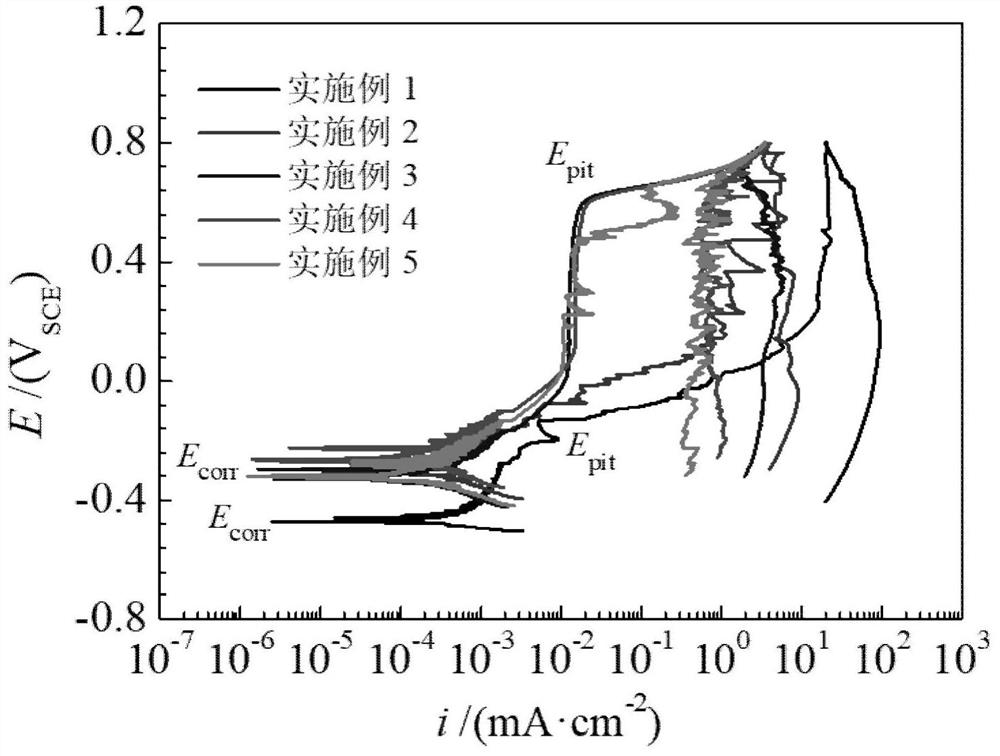

Embodiment 1

[0030] Blank control group, soaked only in marine environment.

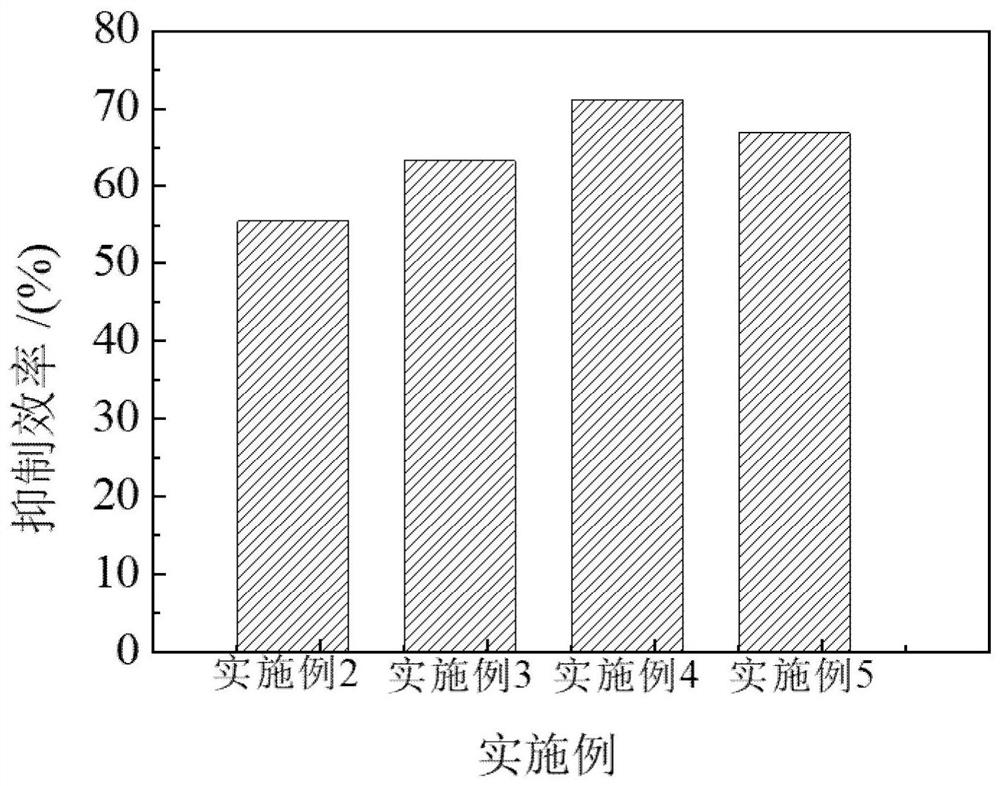

Embodiment 2

[0032] The rust inhibitor of this embodiment is composed of the following parts by mass: 0.25 parts of sodium molybdate and 100 parts of water. The rust inhibitor is obtained by the following method: weigh each component according to the mass fraction, add it into an alkaline solution with a pH of 13.5 at room temperature (25° C.) and stir it evenly with a glass rod to obtain it.

Embodiment 3

[0034] The rust inhibitor of this embodiment is composed of the following parts by mass: 0.25 parts of sodium molybdate, 0.12 parts of benzotriazole, and 100 parts of water. The rust inhibitor is obtained by the following method: weigh each component according to the mass fraction, add it into an alkaline solution with a pH of 13.5 at room temperature (25° C.) and stir it evenly with a glass rod to obtain it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com