Ultralow-dosage corrosion inhibitor and preparation method thereof

A rust inhibitor and ultra-low technology, applied in the field of rust inhibitor preparation, can solve the problems of corrosion, toxic rust inhibitor performance, carcinogenicity, etc., and achieve the effects of improving concrete strength, excellent rust inhibitor performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

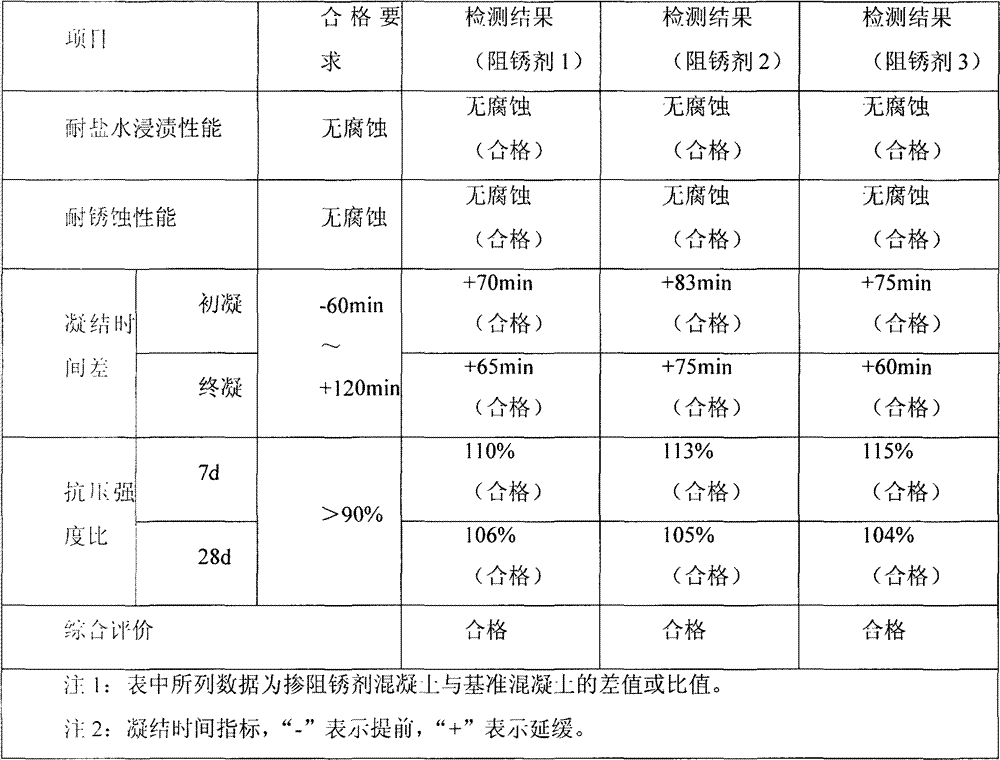

Examples

Embodiment 1

[0043] Prepare the rust inhibitor with ultra-low dosage, wherein, prepare materials according to the following component contents:

[0044] Monofluorophosphosodium: 0.4%;

[0045] Mineral admixture: 99.6%; (the mineral admixture is fly ash with a specific surface area of 280m 2 / kg).

[0046] Adding an ultra-low dosage of rust inhibitor accounting for 5% of the cement weight will prevent steel bars from corroding.

[0047] The above-mentioned materials are mixed in proportion until uniform, and the finished product is obtained.

Embodiment 2

[0049] Prepare the rust inhibitor with ultra-low dosage, wherein, prepare materials according to the following component contents:

[0050] Sodium monofluorophosphate: 0.8%;

[0051] Mineral admixture: 99.2%; (mineral admixture is coal gangue, specific surface area 285m 2 / kg).

[0052] Adding an ultra-low dosage of rust inhibitor accounting for 5% of the cement weight will prevent steel bars from corroding.

[0053] The above-mentioned materials are mixed in proportion until uniform, and the finished product is obtained.

Embodiment 3

[0055] Prepare the rust inhibitor with ultra-low dosage, wherein, prepare materials according to the following component contents:

[0056] Sodium monofluorophosphate: 1%;

[0057] Mineral admixture: 99%; (the mineral admixture is alumite, specific surface area 291m2 / kg).

[0058] Adding an ultra-low dosage of rust inhibitor accounting for 5% of the cement weight will prevent steel bars from corroding.

[0059] The above-mentioned materials are mixed in proportion until uniform, and the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com