Anti-corrosion rust inhibitor for concrete and preparation method of anti-corrosion rust inhibitor

A rust inhibitor and concrete technology, applied in the field of building material additives, can solve problems such as inability to absorb sulfate ions, achieve significant rust and sulfate corrosion resistance, good sulfate corrosion resistance and rust resistance, construction operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

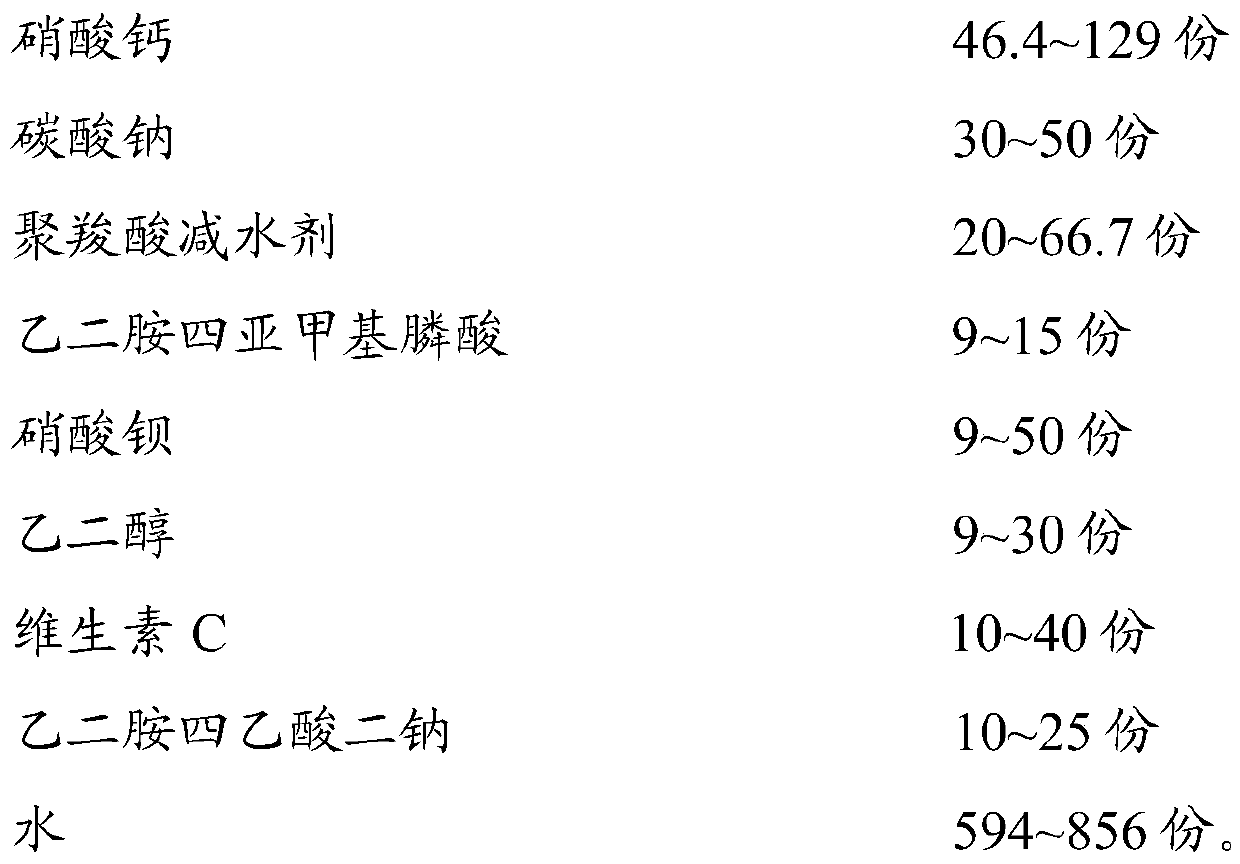

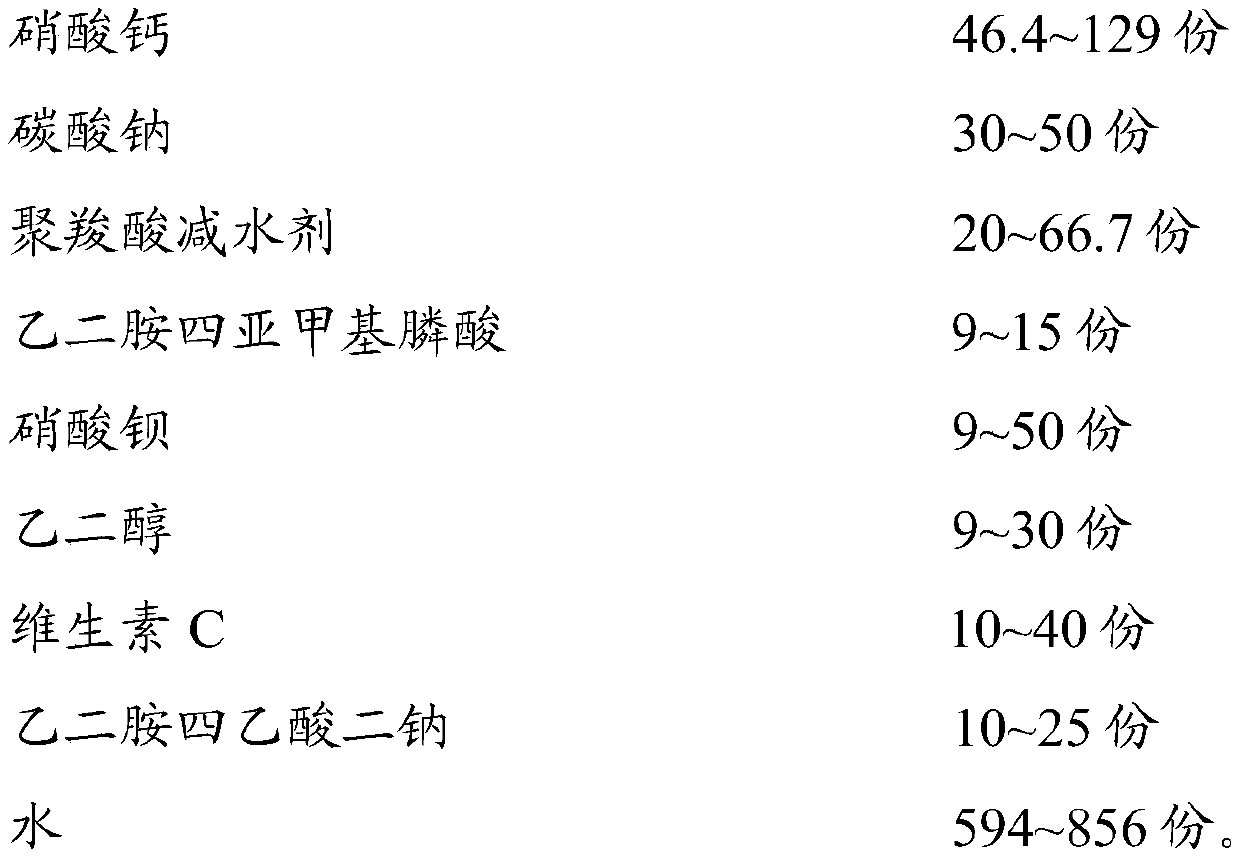

Method used

Image

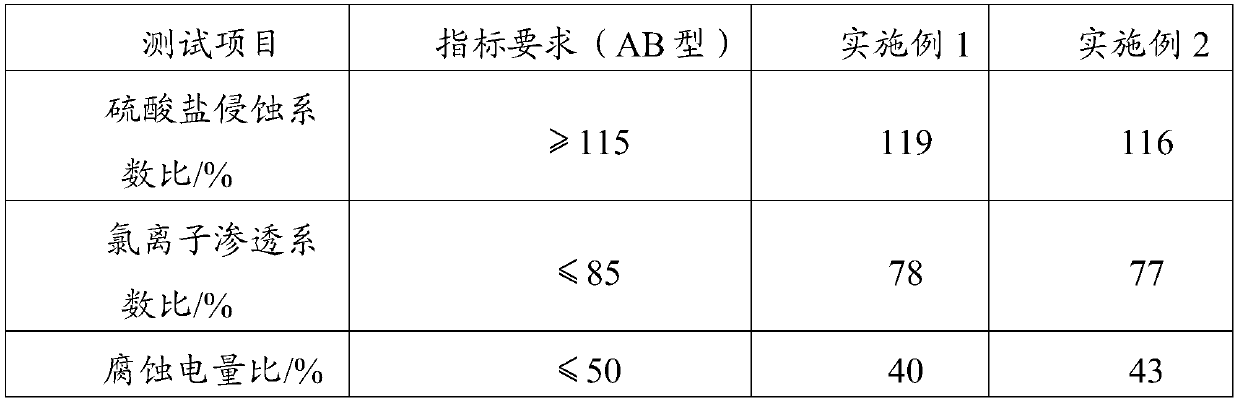

Examples

Embodiment 1

[0027] Dissolve 104.7g of calcium nitrate tetrahydrate in 100ml of water to prepare a calcium nitrate solution, and dissolve 47.0g of sodium carbonate in 250ml of water to prepare a sodium carbonate solution;

[0028] Dissolve 22.2g of polycarboxylate water-reducing agent and 10.5g of ethylenediaminetetramethylenephosphonic acid in 231ml of water and place it in a flask, then add calcium nitrate solution and sodium carbonate solution dropwise to the flask at a constant speed, and the reaction is performed at 20 ℃, the whole dropping process is 1.5h, and the nano calcium carbonate suspension is obtained.

[0029] Dissolve 22.9 g of barium nitrate, 17.5 g of ethylene glycol, 29.2 g of vitamin C, and 15.3 g of disodium EDTA in 150 ml of water, and put the mixed aqueous solution into the above-mentioned nano-calcium carbonate suspension and stir evenly.

[0030] The polycarboxylate water reducing agent is obtained by radical copolymerization of acrylic acid and prenyl polyoxyethyl...

Embodiment 2

[0032] Dissolve 121.1g of calcium nitrate tetrahydrate in 100ml of water to prepare a calcium nitrate solution, and dissolve 49.4g of sodium carbonate in 250ml of water to prepare a sodium carbonate solution;

[0033] Dissolve 26.7g of polycarboxylate water-reducing agent and 9.0g of ethylenediaminetetramethylenephosphonic acid in 217ml of water and place it in a flask, then add calcium nitrate solution and sodium carbonate solution dropwise to the flask at the same time, and the reaction is performed at 25 ℃, the whole dropping process is 2h, and the nano calcium carbonate suspension is obtained.

[0034] 30.5g of barium nitrate, 11.5g of ethylene glycol, 25g of vitamin C, and 10g of disodium EDTA were dissolved in 150ml of water, and the mixed aqueous solution was put into the above-mentioned nano-calcium carbonate suspension and stirred evenly.

[0035] The polycarboxylate water reducing agent is obtained by radical copolymerization of acrylic acid and prenyl polyoxyethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com