Migrating rust inhibitor

A rust inhibitor and migration type technology, applied in the field of migration type rust inhibitor, can solve the problems of weak migration ability and poor rust inhibition effect, and achieve the effect of strong migration ability, good rust inhibition effect and reduction of engineering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

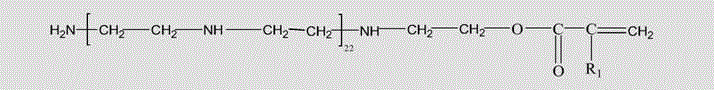

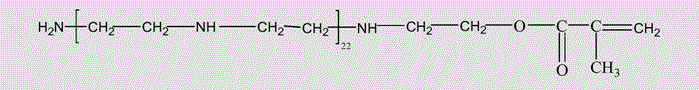

[0018] A migration type rust inhibitor is made of the following components by weight: 80 parts of rust inhibitor, 20 parts of polycarboxylic acid water reducer (fixed solid), 15 parts of sodium gluconate, 0.5 parts of air-entraining agent, 600 parts of water; wherein the rust-inhibiting component is:

[0019]

[0020] The preparation method of the present invention is as follows:

[0021] Polyethylenediamine with a degree of polymerization of 3 and (meth)acrylic acid were esterified according to a mass ratio of 1:1.05 to prepare the above-mentioned rust-inhibiting component, which was combined with (methyl) in a mass ratio of 1:3. ) Acrylic acid is mixed, and 0.02 free radical initiator ammonium persulfate is added into it to perform polymerization reaction at a temperature of 80° C. to prepare the migration type rust inhibitor of the present invention.

Embodiment 2

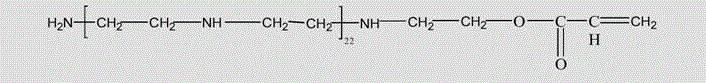

[0023] A migration type rust inhibitor is made of the following components by weight: 150 parts of rust inhibitor, 25 parts of polycarboxylic acid water reducer (fixed solid), 40 parts of sodium gluconate, 1 part of air-entraining agent, 800 parts of water; wherein the rust-inhibiting component is:

[0024]

Embodiment 3

[0026] A migration type rust inhibitor is made of the following components by weight: 100 parts of rust inhibitor, 20 parts of naphthalene water reducer (fixed solid), 20 parts of sodium citrate, 0.5 parts of air-entraining agent, and 575 parts of water Parts; wherein, the rust-inhibiting component is:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com