Surface treating agent for fabric coating and preparation thereof

A surface treatment agent and coating technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of not having self-cleaning function, the membrane material is easy to be stained with dust and dirt, and the service life of the membrane material is affected, so as to achieve improvement and The effect of improving the performance of membrane materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The fabric PVC coating surface treatment agent of the present invention and its preparation method are further described in detail below.

[0016] The anti-ultraviolet function in this invention is mainly composed of acrylic monomers with hydroxyl groups having anti-ultraviolet functions, and acrylic monomers with other functional groups, polyethylene series monomers, copolymers and solvents are added.

[0017] The acrylic resin used in the invention is composed of acrylic monomers containing hydroxyl groups with ultraviolet absorbing functions, acrylic monomers containing non-active groups and acrylic monomers containing carbonyl groups.

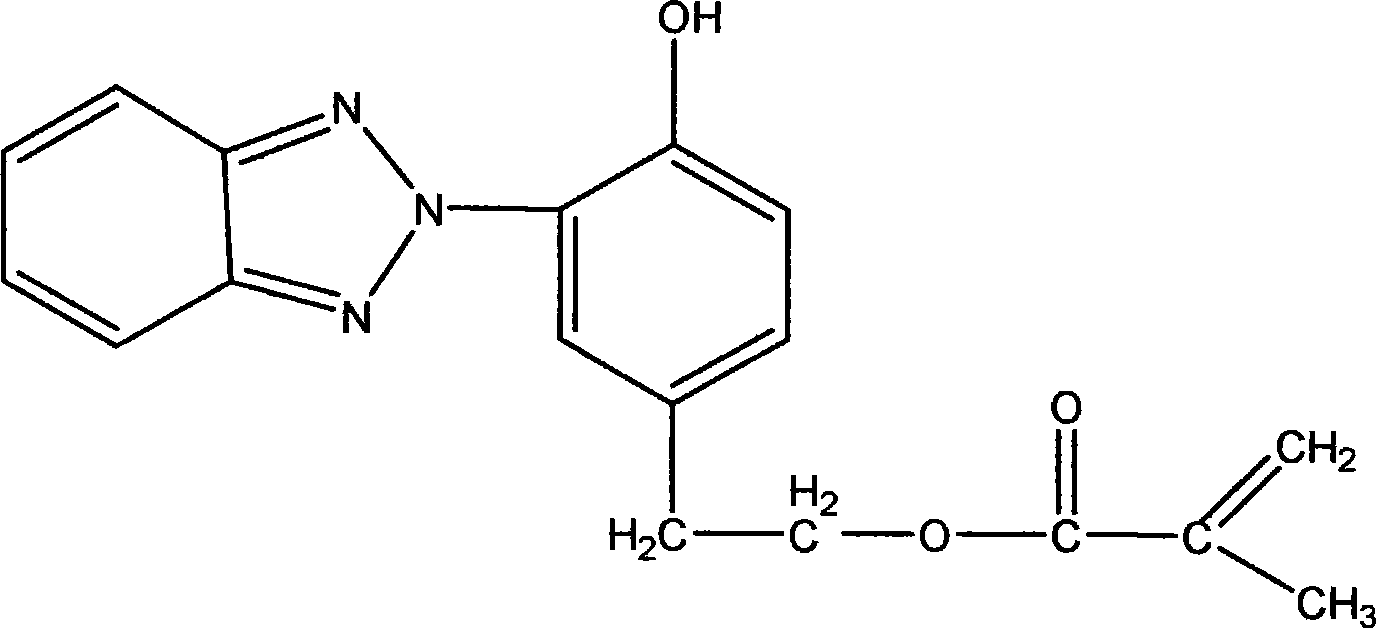

[0018] In this invention, the hydroxyl-containing acrylic monomer having the function of absorbing ultraviolet rays in Chemical Formula 1 is specially used, thereby improving the weather resistance to ultraviolet rays. The above-mentioned monomers have been commercially produced by Otsuka Chemical Company, and Chemical Formula 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com