Preparation method of aluminum gusset plate with super-hydrophobic surface and aluminum gusset plate with super-hydrophobic surface

A technology of super-hydrophobic surface and aluminum buckle plate, which is applied to the device for coating liquid on the surface, special surface, paint containing biocide, etc., which can solve the cumbersome preparation method, difficulty in preparing with super-hydrophobic surface, and reduce the surface energy of the surface and other problems, to achieve the effect of easy-to-obtain raw materials, high practical value, and improve adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method that has superhydrophobic surface aluminum gusset plate, specifically as follows:

[0028] Nano-scale silica pretreatment: Take 2.12g of nano-silica particles, place the cross-linking agent and dispersant in the pre-treatment solvent, wherein the amount of cross-linking agent is 30% of the mass of the silica particles, and the amount of dispersant is two 20% of the mass of silicon oxide particles, adjust the pH to 9, and ultrasonically treat at 30 kHz for 1 hour to obtain surface-modified silicon dioxide particles. The crosslinking agent is dicumyl peroxide; the dispersant is acrylic acid-(meth)acrylate copolymer, and the pretreatment solvent is absolute ethanol.

[0029] Preparation of coating sol: Dissolve 1.02g of pretreated nano-scale silica balls in absolute ethanol, add 0.51g of silane coupling agent KH-550, stir evenly at room temperature, then add water-based epoxy resin coating 1.15 g, hydrophobic PT...

Embodiment 2

[0033] The present embodiment provides a kind of preparation method that has superhydrophobic surface aluminum gusset plate, specifically as follows:

[0034] Nano-scale silica pretreatment: Take 2.59g of nano-silica particles, place the cross-linking agent and dispersant in the pre-treatment solvent, wherein the amount of cross-linking agent is 30% of the mass of the silica particles, and the amount of dispersant is two 20% of the mass of silicon oxide particles, adjust the pH to 9, and 30 kHz ultrasonic treatment for 1 hour to obtain surface-modified silicon dioxide particles. The crosslinking agent is dicumyl peroxide; the dispersant is alkylphenol polyether phosphate, and the pretreatment solvent is absolute ethanol.

[0035]Preparation of coating sol: Dissolve 0.59g of the pretreated nano-scale silica spheres in absolute ethanol, add 0.24g of silane coupling agent KH-550, stir evenly at room temperature, and then add water-based epoxy resin coating 0.68g, hydrophobic PTF...

Embodiment 3~5

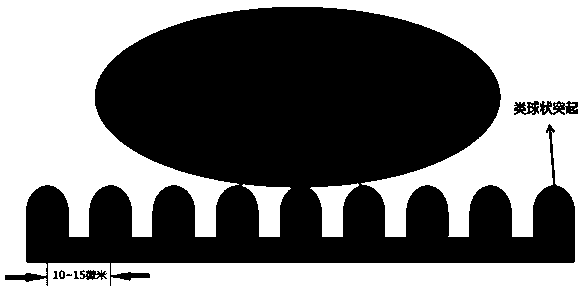

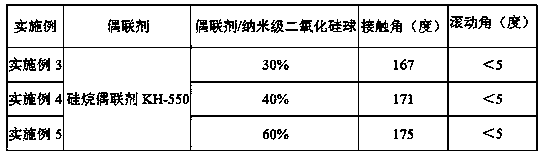

[0041] Examples 3-5 compared the influence of different silane coupling agents KH-550 on the surface contact angle of the epoxy resin superhydrophobic coating of the final aluminum gusset plate.

[0042] Preparation of coating sol: take respectively 0.52 g of nano-scale silica spheres pretreated in Example 1 and dissolve them in absolute ethanol, add 30%, 40% and 60% of nano-scale silica spheres respectively The joint agent KH-550 was stirred evenly at room temperature, then 1.15g of water-based epoxy resin coating and 0.55g of hydrophobic PTFE were added, and the reaction was continuously stirred to obtain a coating sol.

[0043] Application of coating sol: put the aluminum buckle plate in the above coating sol, lift it out from the coating sol at a slow and uniform speed with a pulling machine, and the pulling speed is 60mm / s; after putting it out, let it stand at room temperature for use;

[0044] Forming of epoxy resin super-hydrophobic coating: Put the coated aluminum gus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com