Hydrogen-gasoline mixed fuel rotary engine and control method

A rotary engine and mixed fuel technology, applied in the direction of engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of restricting development and application, uneven mixing, high fuel consumption, etc., to reduce fuel consumption and emissions, improve combustion, reduce The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

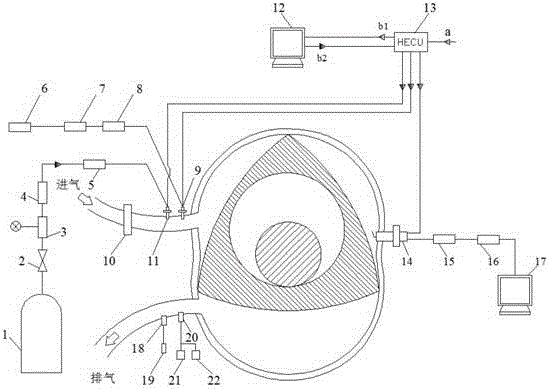

[0020] Hydrogen-gasoline mixed fuel rotary engine and control method device, the device is used to improve the performance of hydrogen-gasoline mixed fuel rotary engine, including hydrogen tank 1, hydrogen pipeline switch 2, hydrogen pipeline decompression valve 3, hydrogen flowmeter 4 , flame retardant valve 5, gasoline tank 6, gasoline pump 7, gasoline flow meter 8, gasoline nozzle 9, air flow meter 10, hydrogen nozzle 11, calibration computer 12, mixed fuel electronic control unit 13, spark plug cylinder pressure sensor 14, Charge amplifier 15, A / D converter 16, combustion analyzer 17, oxygen sensor 18, air-fuel ratio analyzer 19, exhaust gas sampling pipe 20, regulatory emission analyzer 21, exhaust gas analyzer 22, data signal sent by a sensor to HECU (The data signals include eccentric shaft speed signal, throttle position signal, air-fuel rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com