Calcareous sand reinforced cement-based material and preparation method thereof

A technology for strengthening cement and base materials, applied in the field of strengthening cement, can solve the problems of increasing construction cost, increasing construction cost, increasing transportation cost, etc., and achieve the effect of shortening construction period, reducing construction cost and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

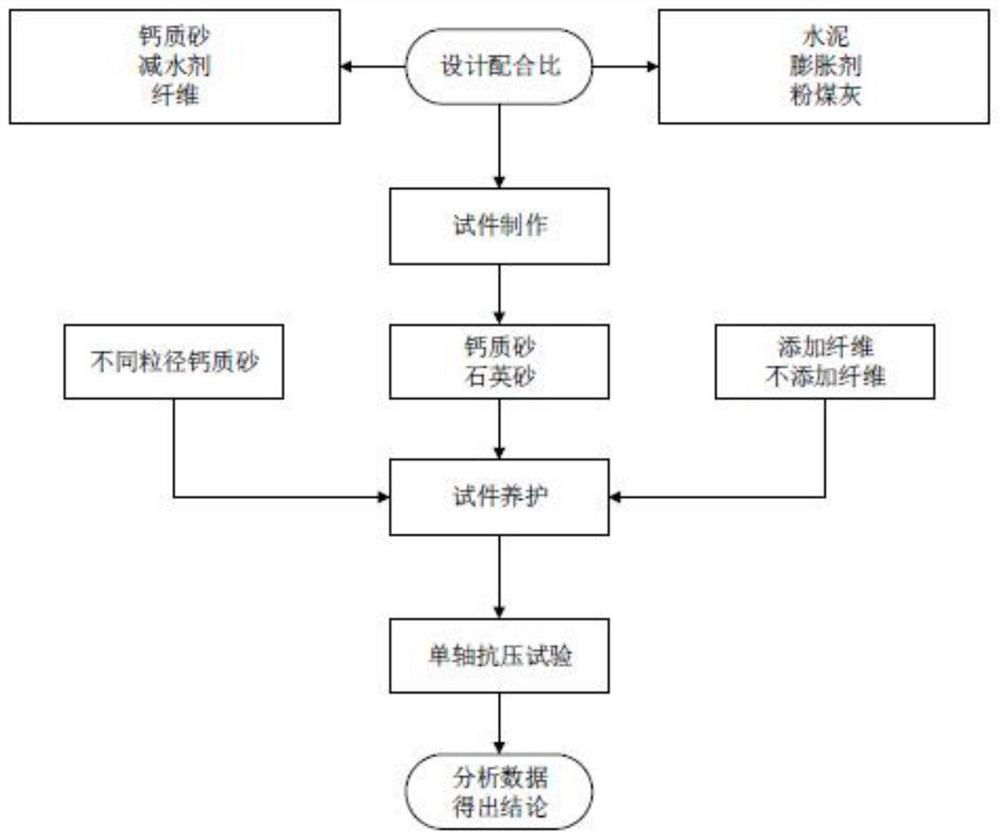

Method used

Image

Examples

Embodiment 1

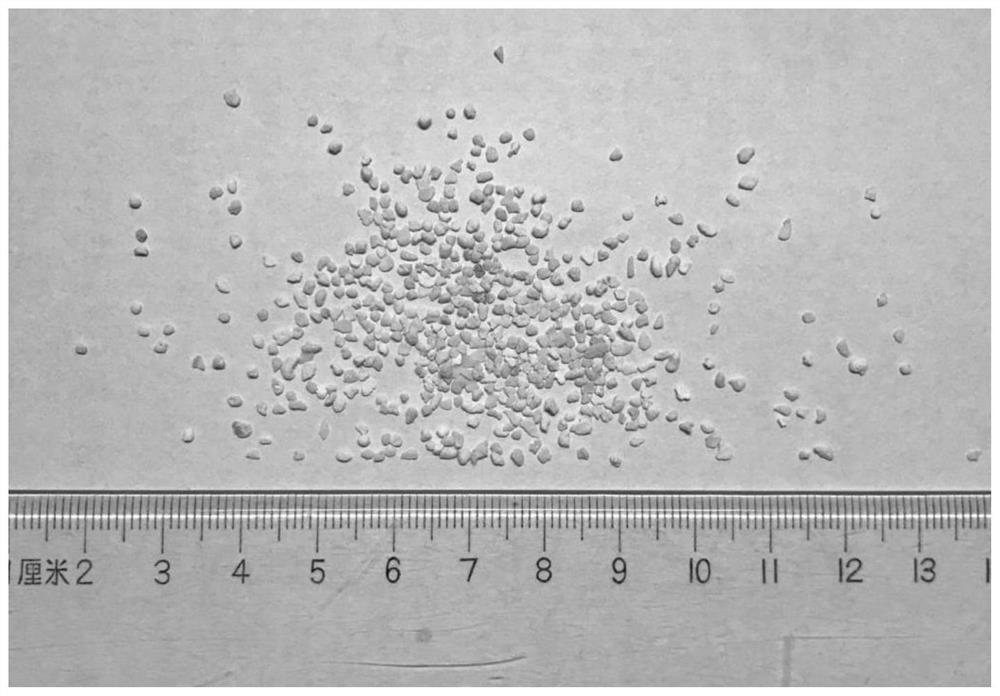

[0033] Weigh the raw materials according to the raw material ratio in Table 1; among them, A-1, 2, 3, B-1, 2, 3 aggregates are quartz sand, C-1, 2, 3, D-1, 2, 3, E- 1, 2, 3, F-1, 2, and 3 aggregates are calcareous sand with particle sizes of 0.25-0.5mm, 0.5-1.0mm, 1.0-2.0mm, and 0.25-0.5mm respectively; the unit in Table 1 is kg;

[0034] Table 1

[0035] Numbering cement fly ash expansion agent aggregate water fiber Superplasticizer A-1,2,3 575.80 164.51 82.27 411.28 205.64 0.00 15.83 B-1,2,3 575.80 164.51 82.27 411.28 205.64 0.00 10 C-1,2,3 575.80 164.51 82.27 411.28 205.64 0.00 10 D-1,2,3 575.80 164.51 82.27 411.28 205.64 0.00 15 E-1,2,3 575.80 164.51 82.27 411.28 205.64 0.00 15 F-1,2,3 599.81 171.37 85.70 428.43 214.21 0.00 15

[0036] Prepare the test piece as follows:

[0037] 1. Mixing of concrete mixture

[0038] (1) Prepare materials according to the determined mixing ratio...

Embodiment 2

[0054] Weigh raw materials according to the raw material ratio in Table 3; wherein, 2-A-1, 2, 3 aggregates are quartz sand, 2-B-1, 2, 3, 2-C-1, 2, 3, 2-D- 1, 2, 3, 2-E-1, 2, 3, 2-F-1, 2, 3 aggregates have particle sizes of 0.075-0.25mm, 0.25-0.5mm, 0.5-1.0mm, 1.0-2.0 mm, 0.25-0.5mm calcareous sand; the unit in Table 3 is kg;

[0055] table 3

[0056]

[0057]

[0058] Preparation method and uniaxial compression test are the same as in Example 1; the results are shown in Table 4;

[0059] Table 4

[0060]

[0061] This example is a performance comparison between cement-based materials and calcareous sand materials with a volume ratio of 1.7% without adding fibers;

[0062] The data in Table 4 shows that if the fiber is added according to the fiber volume ratio of the original quartz sand, the fiber mixing ratio is too high, the strength is low, and the sample is seriously agglomerated during stirring, which makes the mixer unable to operate. The ratio cannot satisf...

Embodiment 3

[0065] Weigh the raw materials according to the ratio of raw materials in Table 5; among them, 3-A-1, 2, 3, 3-B-1, 2, 3, 3-C-1, 2, 3, 3-D-1, 2, 3 , 3-E-1, 2, 3, 3-F-1, 2, 3 aggregates have particle sizes of 0.075-0.25mm, 0.25-0.5mm, 0.5-1.0mm, 1.0-2.0mm, 0.25-0.5 mm, 0.25-0.5mm calcareous sand; the unit in Table 5 is kg;

[0066] table 5

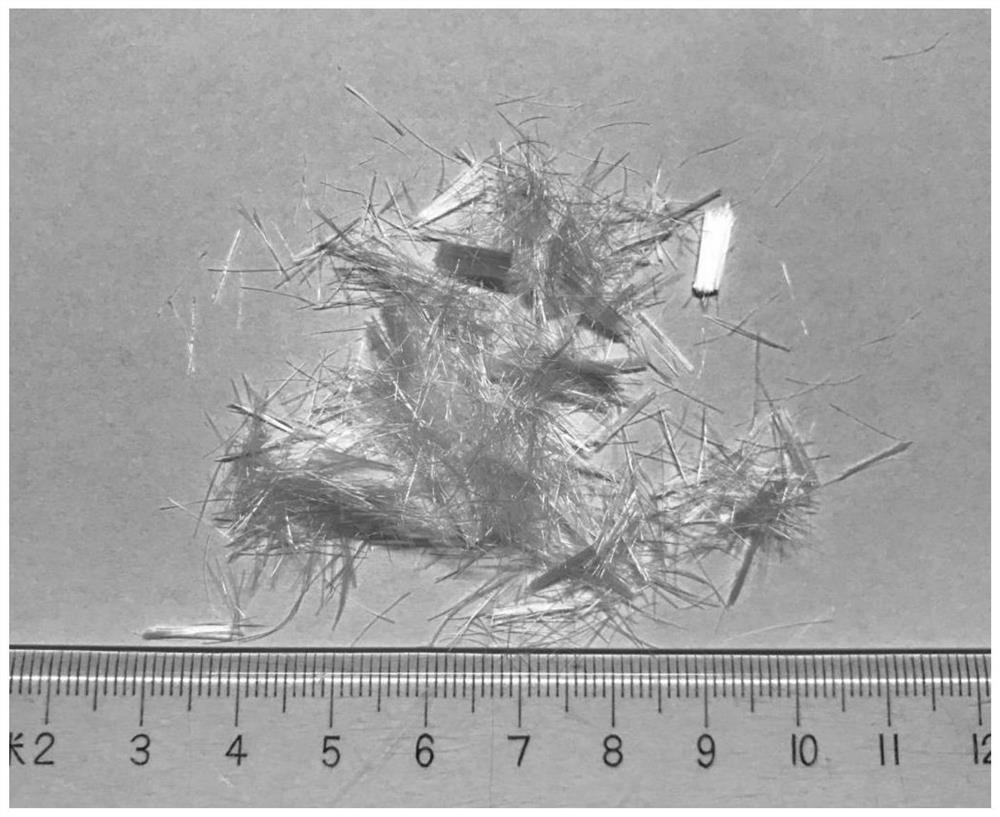

[0067] Numbering cement g fly ash expansion agent aggregate water fiber Superplasticizer 3-A-1,2,3 575.80 164.51 82.27 411.28 205.64 10.72 38.43 3-B-1,2,3 575.80 164.51 82.27 411.28 205.64 10.72 52.76 3-C-1,2,3 575.80 164.51 82.27 411.28 205.64 10.72 37.95 3-D-1,2,3 575.80 164.51 82.27 411.28 205.64 10.72 38.4 3-E-1,2,3 575.80 164.51 82.27 411.28 205.64 5.36 14.25 3-F-1,2,3 575.80 164.51 82.27 411.28 205.64 7.15 13.98

[0068] Preparation method and uniaxial compression test are the same as in Example 1; the results are shown in Table 6;

[0069] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com