Ethyl cellulose sodium monofluorophosphate corrosion inhibitor and its preparation method

A technology of sodium monofluorophosphate and ethyl cellulose, which is applied in the field of inorganic rust inhibitors, can solve the problems that the influence of MFP cannot be ignored, the effect of rust inhibition is reduced, and the effect of rust inhibition is reduced, and the release rate can be controlled and optimized, and the solution is easy Loss of easy oxidation, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The equipment adopts extrusion spheronizer (Shenzhen Xinyite Technology Co., Ltd., LTAES 380 type)

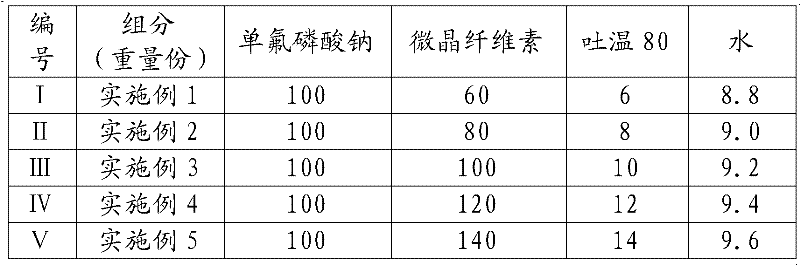

[0055] 1. Capsule core preparation: According to the weight ratio of No. V capsule core in Table 1, first fully mix sodium monofluorophosphate and microcrystalline cellulose, add Tween 80 after mixing, knead evenly and then divide into batches Add purified water so that purified water can exist evenly in the mixture.

[0056] 2. Extrusion and thinning: Turn on the extrusion spheronizer, start the extrusion mode of the equipment, feed materials at the feeding port, and start the cooling water circulation mode of the equipment to prevent the excessive temperature of the extrusion cylinder from affecting the discharge.

[0057] 3. Discharging and rounding: Use a tray to hold the extruded rice strip-shaped capsule core material, pour it into the roller in the equipment, start the rounding mode of the equipment, adjust the rotation rate of the rounding (the speed is controlle...

Embodiment 2

[0062] 1. Capsule core preparation: according to the weight ratio of No. III capsule core in Table 1,

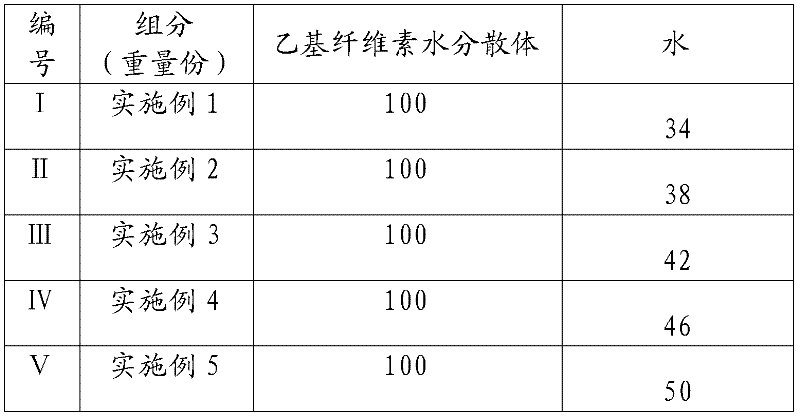

[0063] 2. Coating solution preparation: select the weight ratio of No. III coating in Table 2, and weigh the coating material according to the weight ratio of capsule core and ethylcellulose aqueous dispersion as 1:1.

[0064] Other processing steps, parameter and equipment are with embodiment 1.

Embodiment 3

[0066] 1. Capsule core preparation: according to the weight ratio of No. I capsule core in Table 1,

[0067] 2. Coating solution preparation: select the weight ratio of the V coating in Table 2, and weigh the coating material according to the weight ratio of the capsule core to the dry matter of the coating material as 1:4.

[0068] Other processing steps, parameter and equipment are with embodiment 1.

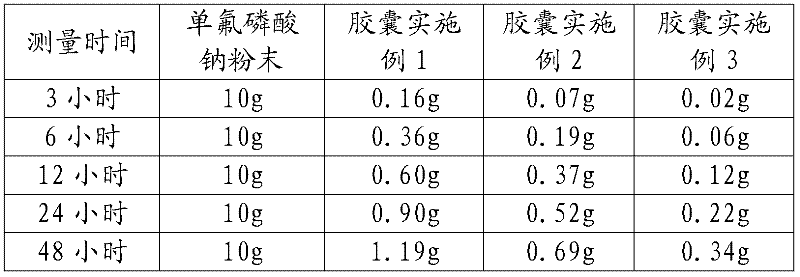

[0069] 2. Particle size range of ethyl cellulose sodium monofluorophosphate corrosion inhibitor capsules:

[0070] The particle size of the ethylcellulose sodium monofluorophosphate microcapsules prepared by this method changes from 350 μm (corresponding capsule core material: the mass ratio of ethylcellulose aqueous dispersion=1: 0.25) to 1000 μm (corresponding capsule core Material: mass ratio of ethyl cellulose aqueous dispersion = 1: 4)

[0071] 4. Microscopic morphology of ethyl cellulose sodium monofluorophosphate corrosion inhibitor capsules

[0072] The morphology o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com