Preparation method of modified polyvinylidene fluoride through chlorotrifluoroethylene

A technology of chlorotrifluoroethylene and polyvinylidene fluoride is applied in the field of preparation of chlorotrifluoroethylene-modified polyvinylidene fluoride, which can solve the problems of difficult processing of high molecular weight components, inability to effectively control molecular weight size and molecular weight distribution, and the like, To achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

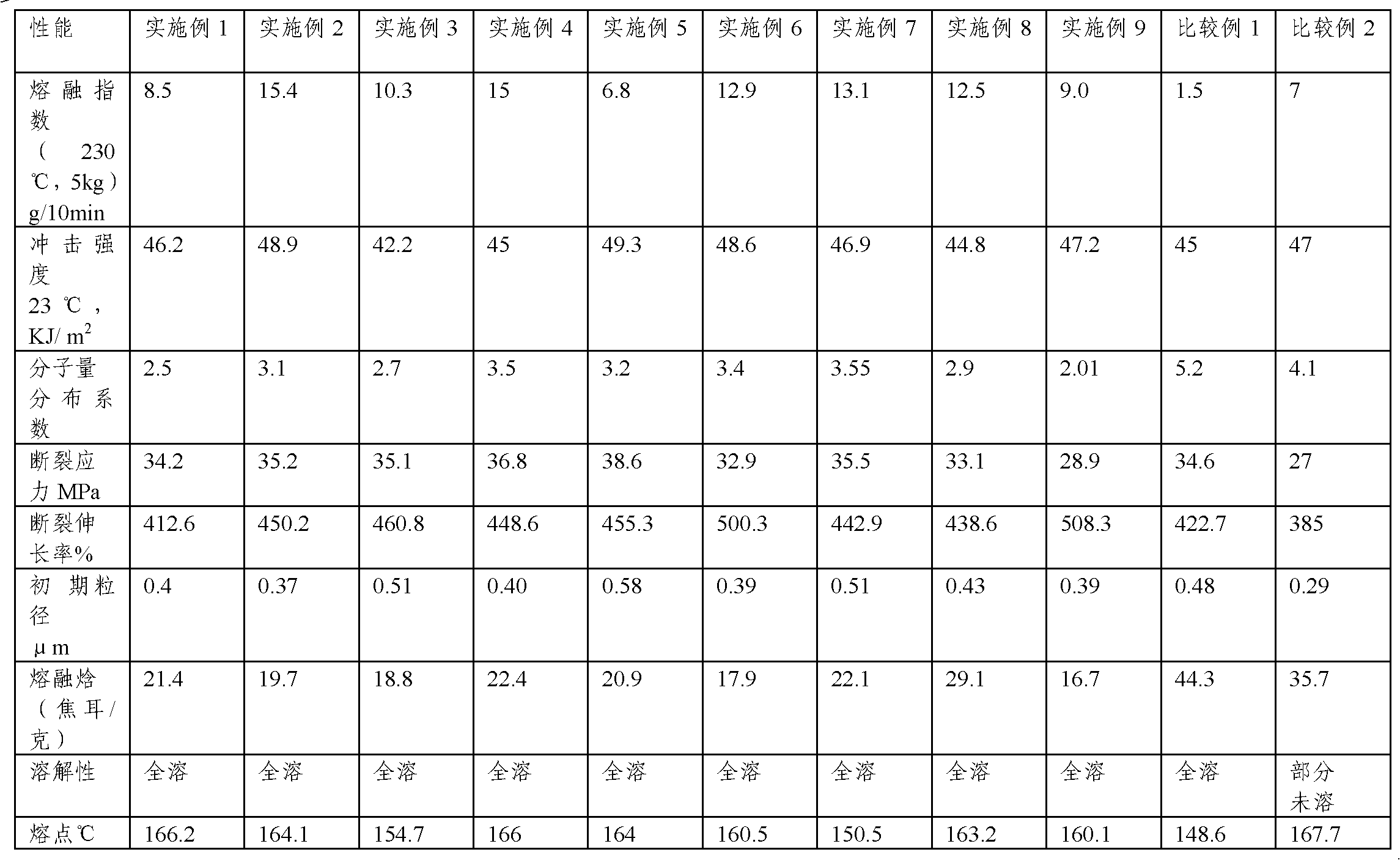

Examples

Embodiment 1

[0050] The preparation of embodiment 1 PVDF-CTFE polymer

[0051] In a 50L stainless steel vertical reaction kettle, add 32kg of water, blow nitrogen and oxygen three times, evacuate until the oxygen content is less than or equal to 25ppm, add 40g of perfluorooctanoic acid, 400ml of liquid paraffin (liquid at normal temperature), start stirring, the speed is 200rpm, and the temperature is raised to 60 ℃, add 95mol% vinylidene fluoride and 5mol% chlorotrifluoroethylene to 2.5MPa, after the system is stable, add 20g of diethyl malonate to the reaction kettle through a metering pump, and add 40ml of IPP after a few minutes (Diisopropyl peroxydicarbonate) dissolved in 15ml of chlorofluorocarbon F113 (CCl 2 FCClF 2 ) into the reactor to start the polymerization reaction. At the same time, keep adding mixed monomers to keep the pressure of the reactor at 2.8MPa, and then add 10ml IPP and 20g diethyl malonate at one time for every 20% increase in conversion rate, and add 4 times un...

Embodiment 2

[0058] In a 50L stainless steel vertical reaction kettle, add 32kg of water, blow nitrogen and oxygen three times, evacuate until the oxygen content is equal to 30ppm, add 40g of sodium perfluorooctanoate, 400ml of liquid paraffin, start stirring at a speed of 200rpm, heat up to 65°C, and add 85mol% of Vinylidene fluoride and 15mol% chlorotrifluoroethylene to 2.5MPa, after the system is stable, 15g of diethyl malonate is added to the reactor by a metering pump, and 40ml of IPP (dicarbonate peroxide) is added to the reactor after a few minutes. isopropyl ester) dissolved in 15ml chlorofluorocarbon F113 (CCl 2 FCClF 2 ) into the reactor to start the polymerization reaction. At the same time, continue to add mixed monomers to keep the pressure of the reactor at 2.8 MPa, and then add 15ml IPP and 15g diethyl malonate at one time for every 20% increase in conversion rate, add 4 times, recover unreacted monomers, and obtain PVDF-CTFE Polymer 15.4Kg. Coagulate the obtained polymer...

Embodiment 3

[0064] In a 50L stainless steel vertical reaction kettle, add 32kg of water, blow nitrogen and oxygen three times, evacuate until the oxygen content is less than or equal to 30ppm, add 40g of ammonium perfluorooctanoate, 400ml of liquid paraffin, start stirring at a speed of 200rpm, heat up to 60°C, and add 80mol% Vinylidene fluoride and 20mol% chlorotrifluoroethylene to 2.8MPa, after the system is stable, after the diethyl malonate of 20g is added to the reactor by a metering pump, 40ml of IPP (diisoperoxydicarbonate Propyl ester) dissolved in 15ml chlorofluorocarbon F113 (CCl 2 FCClF 2 ) into the reactor to start the polymerization reaction. At the same time, continue to add mixed monomers to keep the pressure of the reactor at 2.8 MPa, and then add 12ml IPP and 15g diethyl malonate at one time for every 20% increase in conversion rate, add 4 times, recover unreacted monomers, and obtain PVDF-CTFE Polymer 15Kg. Coagulate the obtained polymer in frozen brine at -45°C, thaw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com