Thermal conducting polymer composite material and preparation method thereof

A technology of thermally conductive polymers and composite materials, applied in the field of polymer materials, can solve the problems of reducing mechanical properties and comprehensive properties of composite materials, and achieve the effects of shortening the processing cycle, improving mechanical properties, and expanding industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Vacuum dry polypropylene and PA6 at 80°C for 12 hours;

[0018] (2) 5 parts by weight of PA6 and 5 parts by weight of boron nitride that have been dried are put into an internal mixer and melt blended at 240° C., and the blending time is 5 minutes to obtain a PA6 / boron nitride mixture; Continue melt-blending the blended material and 95 parts by weight of polypropylene at 240° C., and the blending time is 5 minutes;

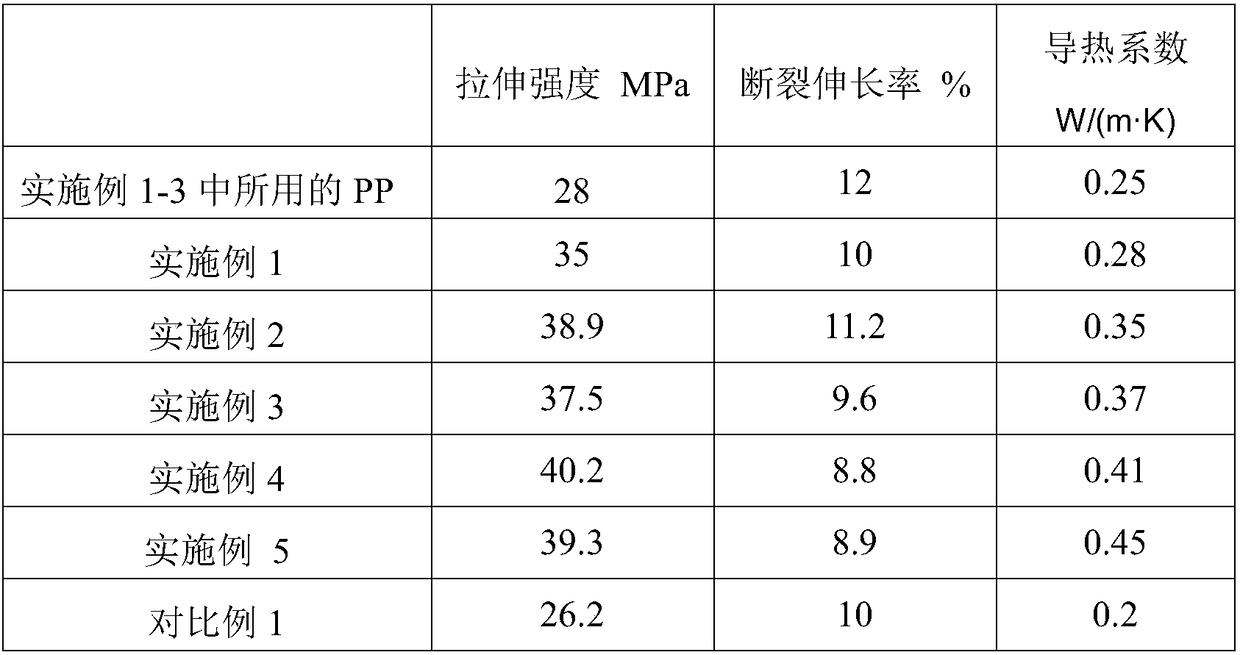

[0019] (3) After drying and granulating, carry out micro-injection molding processing, the injection speed is 300mm / s, the injection temperature is 260°C, the injection pressure is 1200bar, and the mold temperature is 80°C; the shape of the obtained spline is dumbbell-shaped, and the size is 15* 3*0.3mm 3 . The obtained splines were tested for mechanical properties and thermal conductivity, and the performance results are shown in Table 1.

Embodiment 2

[0021] The preparation process is the same as in Example 1, the only difference being: 10 parts by weight of PA6, 5 parts by weight of boron nitride, and 90 parts by weight of polypropylene; the obtained sample strips are tested for mechanical properties and thermal conductivity, and the performance results are shown in Table 1 .

Embodiment 3

[0023] The preparation process is the same as in Example 1, the only difference being: 20 parts by weight of PA6, 5 parts by weight of boron nitride, and 80 parts by weight of polypropylene; the obtained sample strips are tested for mechanical properties and thermal conductivity, and the performance results are shown in Table 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com