Road surface structure of rolling flexiable fibre cement concrete as based and construction method thereof

A cement concrete and flexible fiber technology, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problem that the paving temperature is not lower than 145 °C, the initial pressure temperature is not lower than 135 °C, and the final pressure temperature is generally Not lower than 80 °C, affecting the durability of asphalt stabilized aggregates, fatigue cracking at the bottom of the layer, etc., to achieve the effect of improving the internal structure composition, significant indirect economic and social benefits, and enhancing the ability to resist shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

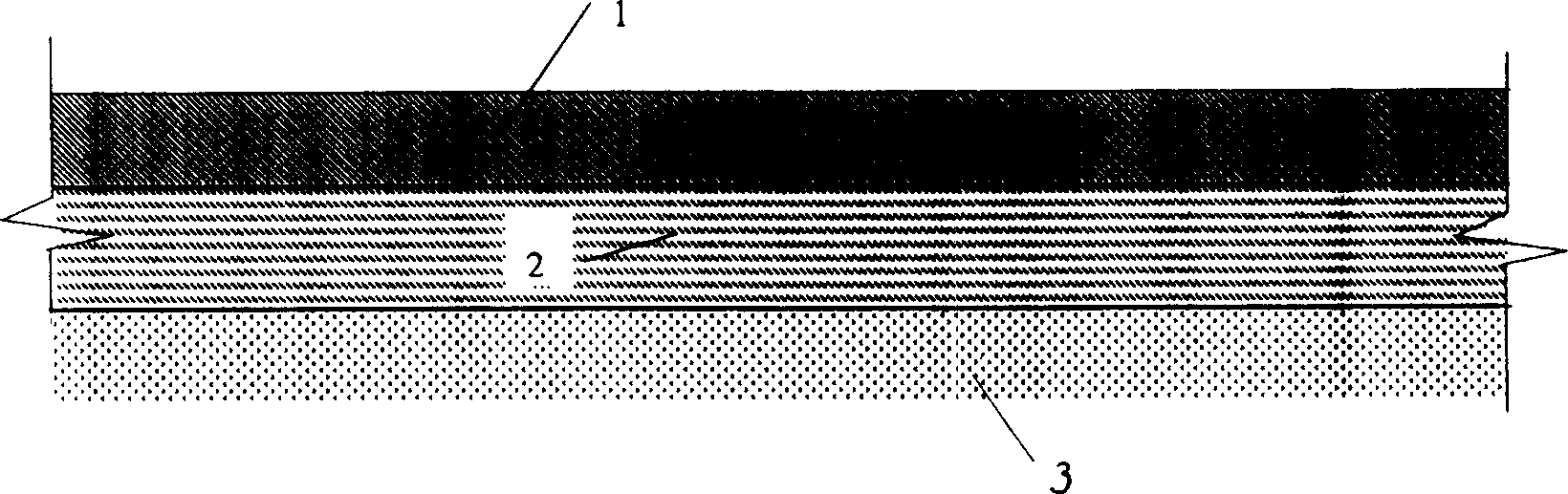

[0043] As shown in the drawings, flexible fiber cement concrete is paved on the surface of the bottom layer 3, and the rolled flexible fiber cement concrete pavement base 2 is formed by rolling, and then the surface layer 1 is paved on the rolled flexible fiber cement concrete pavement base 2.

[0044] Concrete construction method of the present invention:

[0045] A kind of typical embodiment proportioning is (one cubic meter rolls the flexible fiber cement concrete): polypropylene monofilament fiber 1kg, common silicate 32.5 # Put 220kg of cement, 1300kg of gravel with a maximum particle size of no more than 31.5mm, 710kg of river sand, 140kg of fly ash, and 2.2kg of water reducing agent into a mixer and dry mix until uniform, then add 110kg of water for wet mixing until the mixture is mixed Evenly, after the flexible fiber cement concrete mixture is transported to the site, the method of mechanical paving is adopted, and the thickness is 20cm. It is evenly paved on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com