A plasticizer for shale gas well cementing

A plasticizer and shale gas technology, applied in the field of plasticizers, can solve the problems of latex demulsification, difficult performance control, increased friction, etc., and achieve the effect of small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

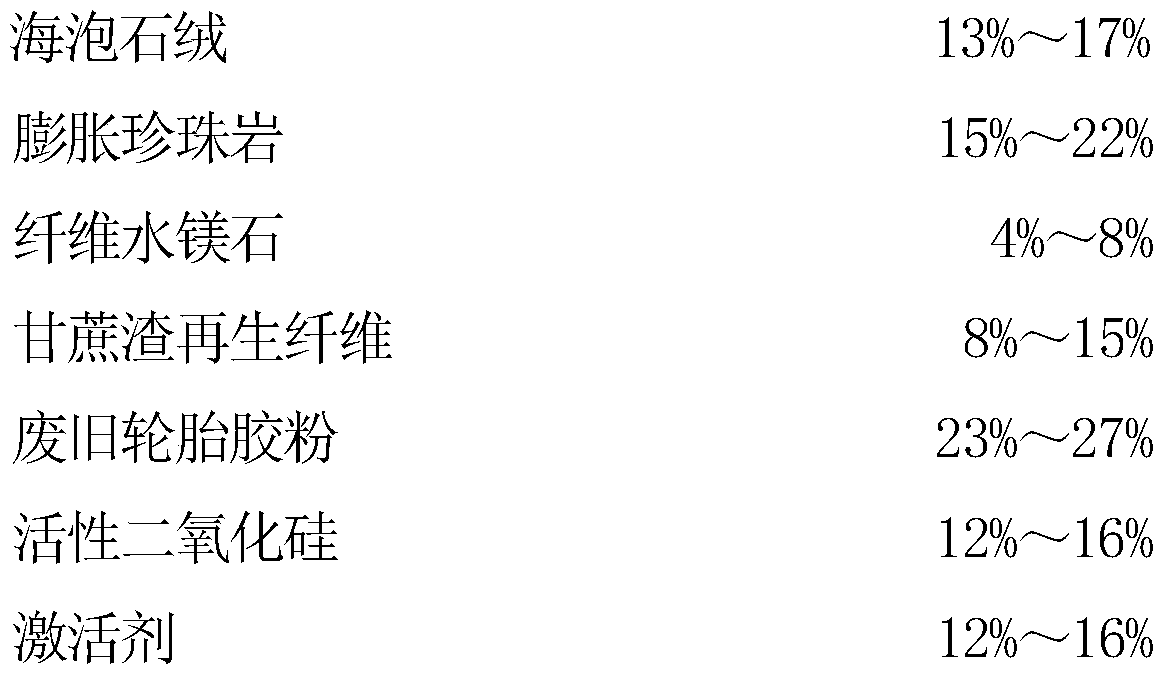

Method used

Image

Examples

Embodiment 1

[0020] Mix 11g sepiolite wool (length 4-8mm), 12g expanded perlite (closed cells, density 1.0-1.3g / cm 3 ), 10g fiber brucite (1-2mm in length, 14-28mm in width), 9g bagasse regenerated fiber (obtained after soaking bagasse in 20% NaOH aqueous solution for 30 minutes), 25g waste tire rubber Powder (40-60 mesh), 20g of active silicon dioxide, and 13g of activator CK21 were evenly mixed to obtain a plasticizer.

Embodiment 2

[0022] Mix 23g sepiolite wool (length 4-8mm), 14g expanded perlite (closed cells, density 1.0-1.3g / cm 3 ), 2g fiber brucite (1-2mm in length and 14-28mm in width), 2g bagasse regenerated fiber (obtained after soaking bagasse in 20% NaOH aqueous solution for 30 minutes), 32g waste tire rubber Powder (40-60 mesh), 17g of active silicon dioxide, and 10g of activator CK21 were evenly mixed to obtain a plasticizer.

Embodiment 3

[0024] Mix 13g sepiolite wool (length 4-8mm), 23g expanded perlite (closed cells, density 1.0-1.3g / cm 3 ), 3g fiber brucite (1-2mm in length and 14-28mm in width), 17g bagasse regenerated fiber (obtained after soaking bagasse in 20% NaOH aqueous solution for 30 minutes), 16g waste tire rubber Powder (40-60 mesh), 12g of active silicon dioxide, and 16g of activator CK21 were evenly mixed to obtain a plasticizer.

[0025] The activator CK21 in the above-mentioned Examples 1-3 can also be replaced by any one or a mixture of two or more of triethanolamine, calcium formate, silicate, carbonate, and chlorate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com