Concrete and preparation method thereof

A technology of concrete and parts by weight, applied in the field of civil engineering materials, can solve problems such as the influence of pumping efficiency and poor fluidity, achieve good dispersion effect, improve fluidity and flow retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

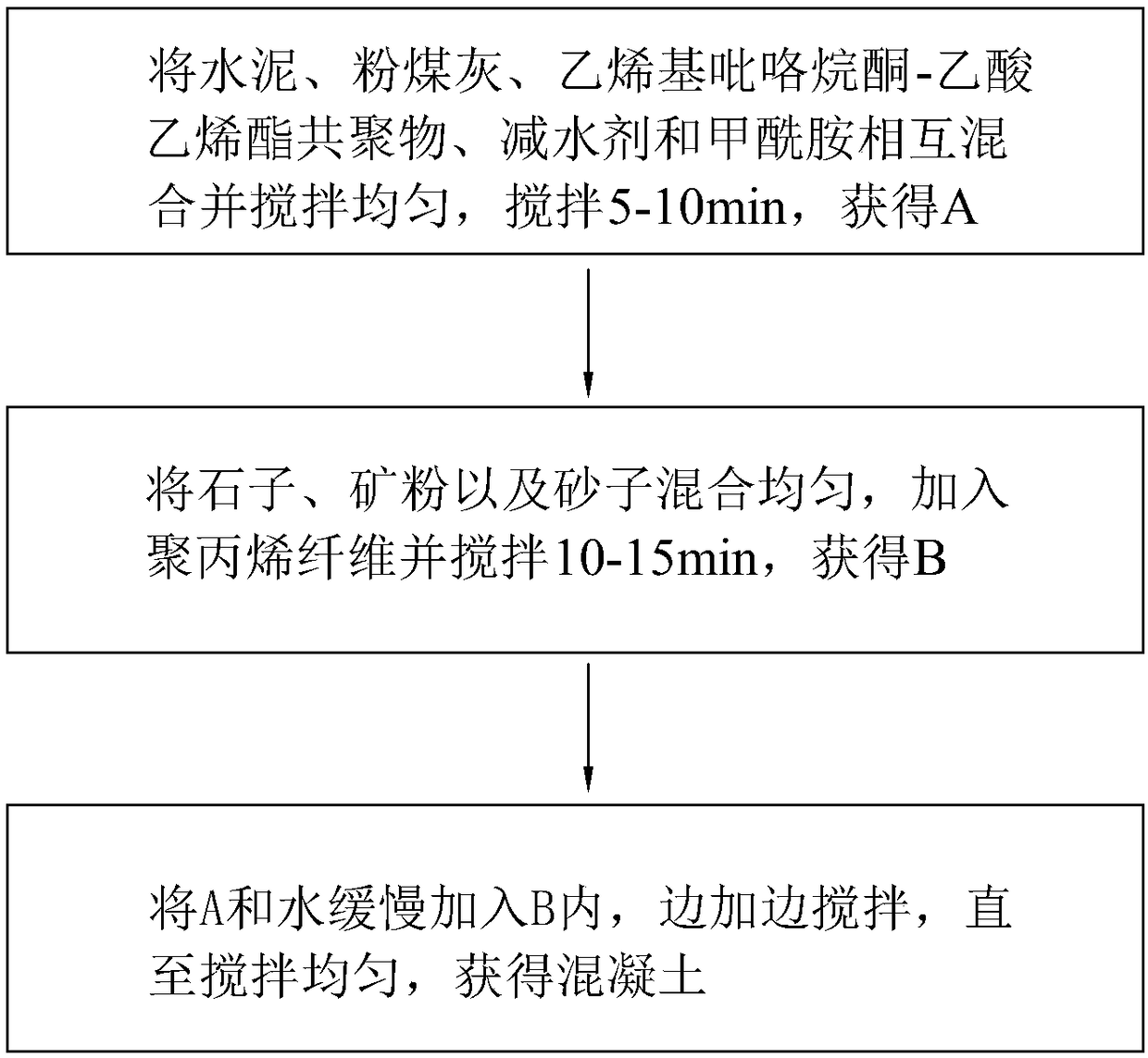

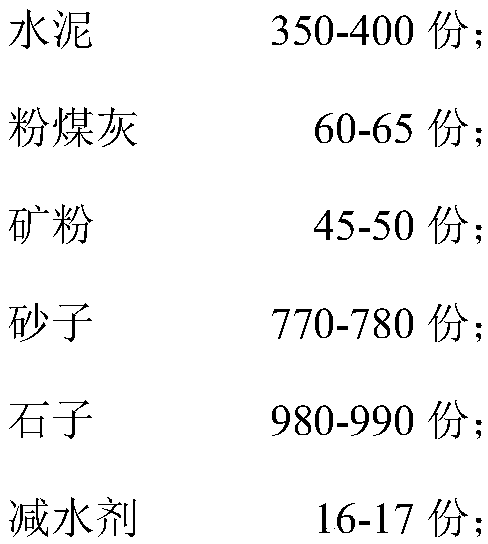

[0051] A kind of concrete, the raw material components are shown in Table 1 in terms of weight fraction, wherein the water reducer is polycarboxylate water reducer (JH23). Wherein, the preparation method of this concrete comprises the following steps:

[0052] Step 1, first mix cement, fly ash, vinylpyrrolidone-vinyl acetate copolymer and formamide with each other and stir evenly for 5-10 minutes;

[0053] Step 2, mix the stone, mineral powder and sand evenly, add polypropylene fiber (2-3mm in length) and stir for 10-15min;

[0054] In step 3, slowly add the mixture in step 1 and water into the mixture in step 2, and stir while adding until the mixture is evenly stirred to obtain concrete.

Embodiment 2

[0056] The difference from Example 1 is that, in parts by weight, the concrete raw material components are shown in Table 1.

Embodiment 3

[0058] The difference from Example 1 is that, in terms of parts by weight, the concrete raw material components are as shown in Table 1 (the polypropylene fibers are removed).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com