Suspended concrete flooring system and method

a technology of suspended concrete and flooring, applied in the direction of girders, walls, joists, etc., can solve the problems of high cost, high labor intensity, and many consumers forced to settle on suspended concrete floors,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

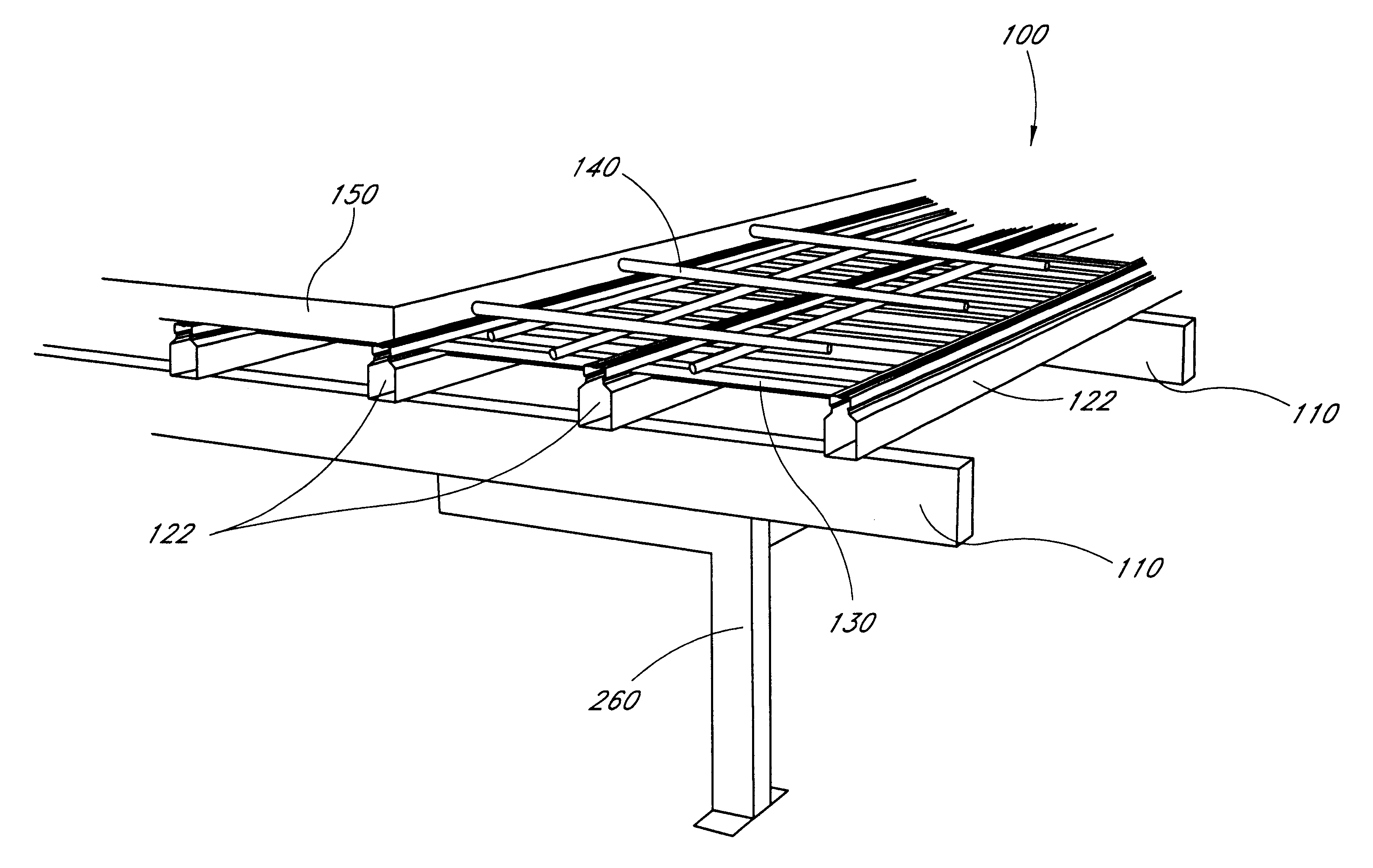

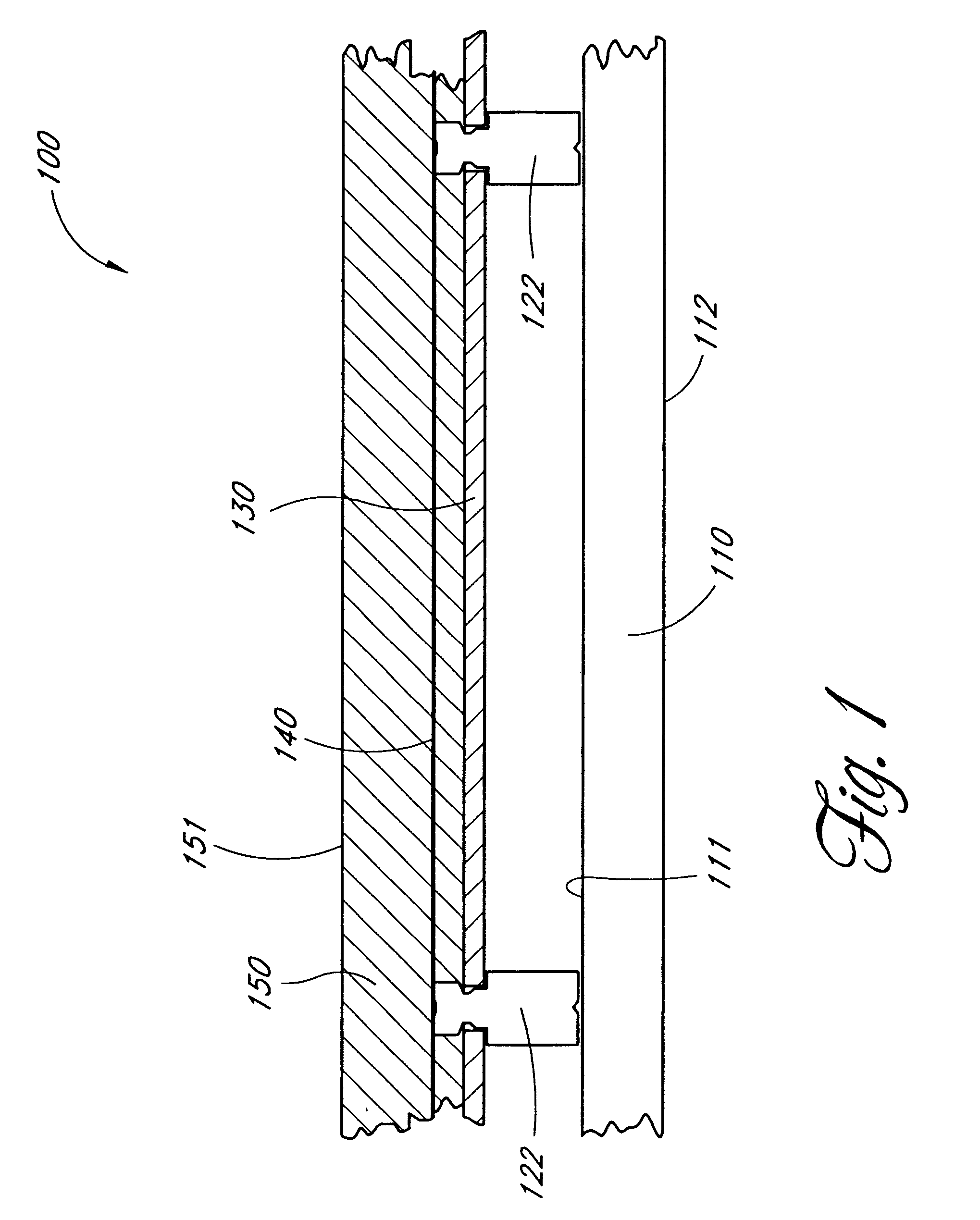

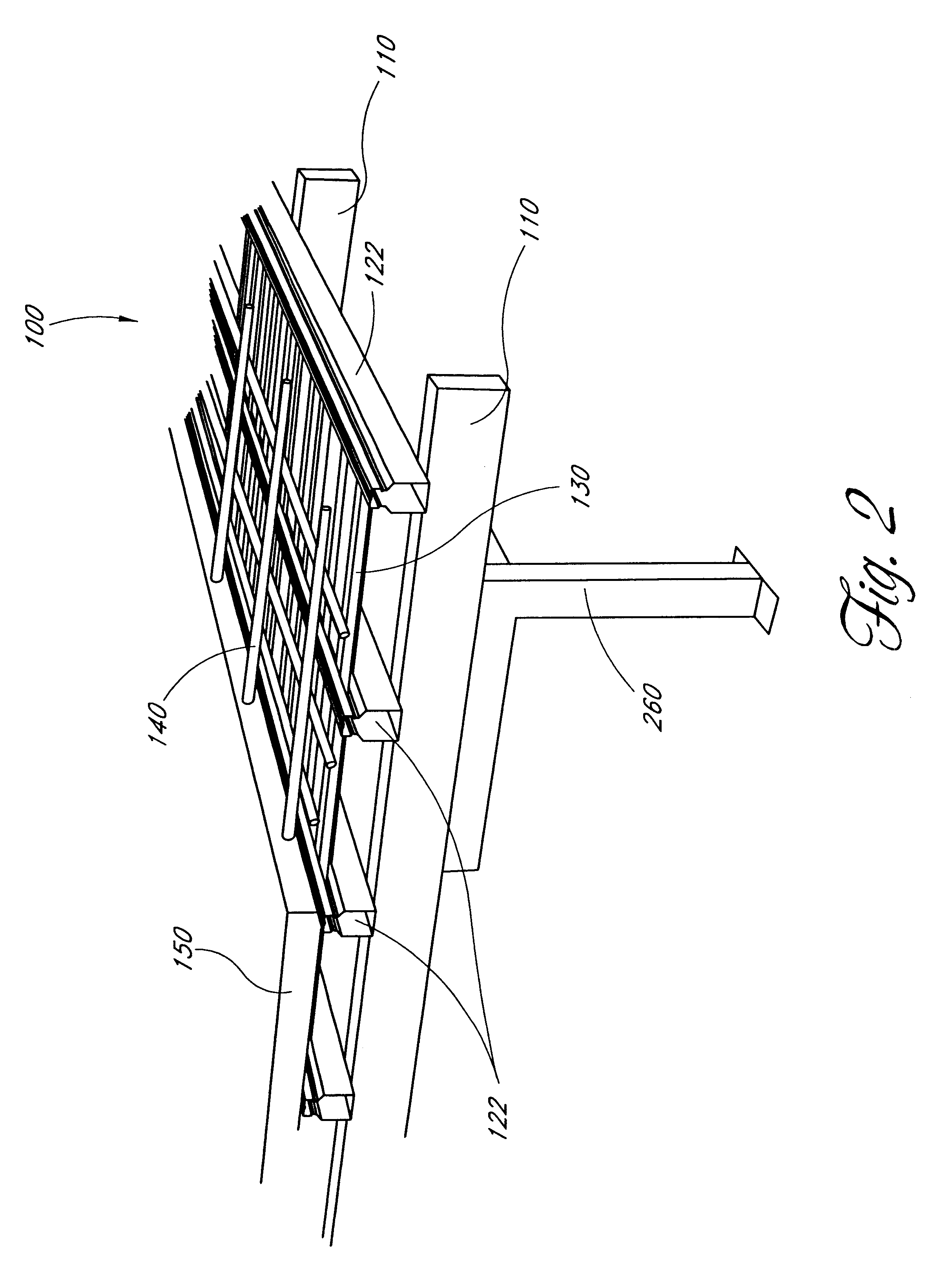

The preferred embodiments disclosed herein solve the above-described problems by combining, among other things, the prior art methods of positioning pre-cast concrete slabs or beams and pouring a floor in situ. Specifically, a pre-cast floor has the benefit of requiring a minimal amount of supportwork, while the poured floor offers the benefits of creating a monolithic floor without the need for slab transportation and heavy machinery installation. This is accomplished by making use of a rigid framework supporting corrugated fiber cement sheets to provide an underlying support layer for a poured in situ concrete floor. The framework includes strong, lightweight load-bearing members or supporting walls and joists arranged so as to allow for a large floor span between supports.

The result is a monolithic concrete floor that is easily constructed, can be installed manually without the need for large machinery, and can span larger unsupported distances thus reducing the necessary framewo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com