Prestress rib tensioning equipment, system and method and concrete continuous box girder

A prestressed tendon and concrete technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve problems such as long time, and achieve the effect of simplifying construction steps, improving construction efficiency, and ensuring project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

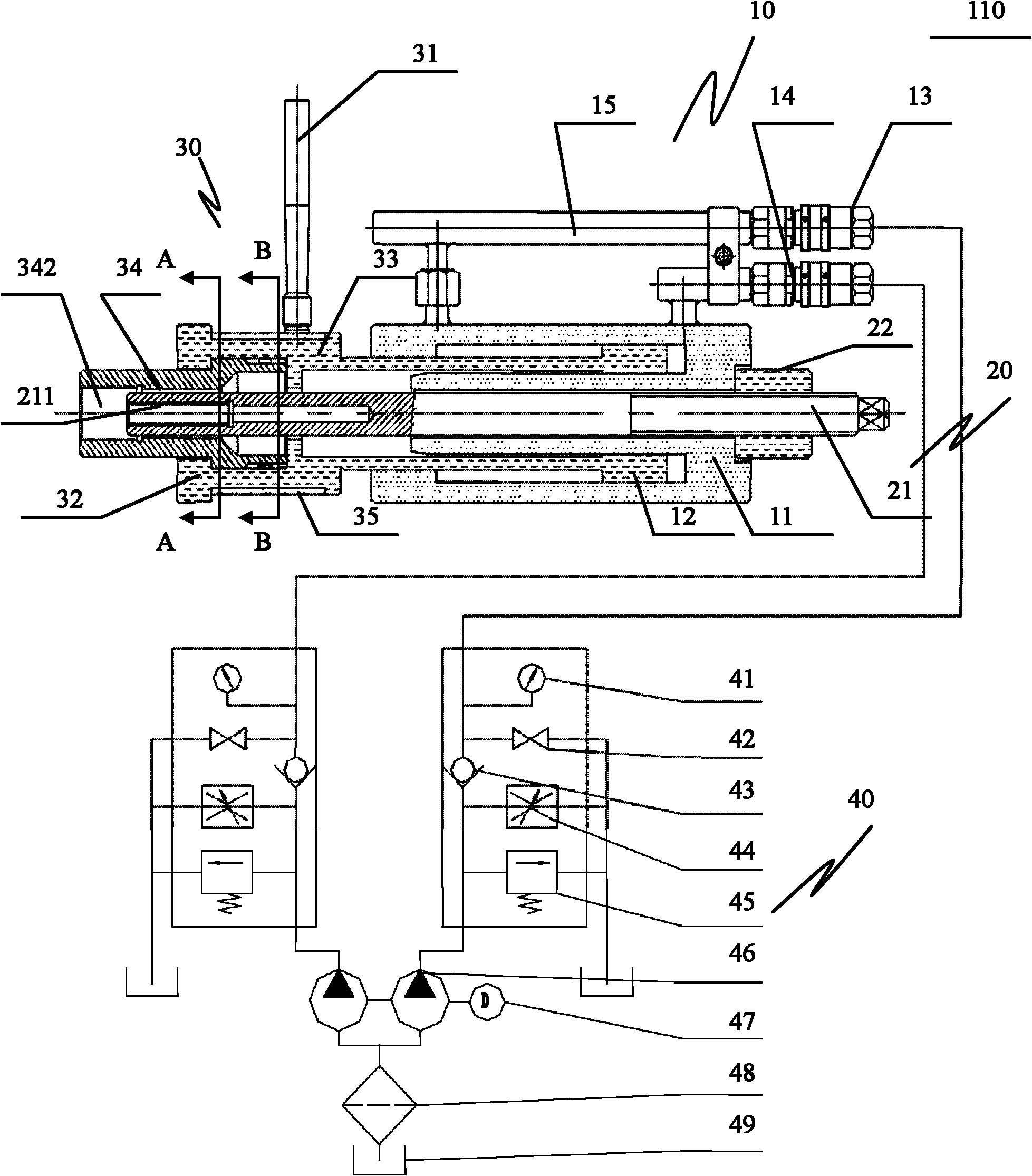

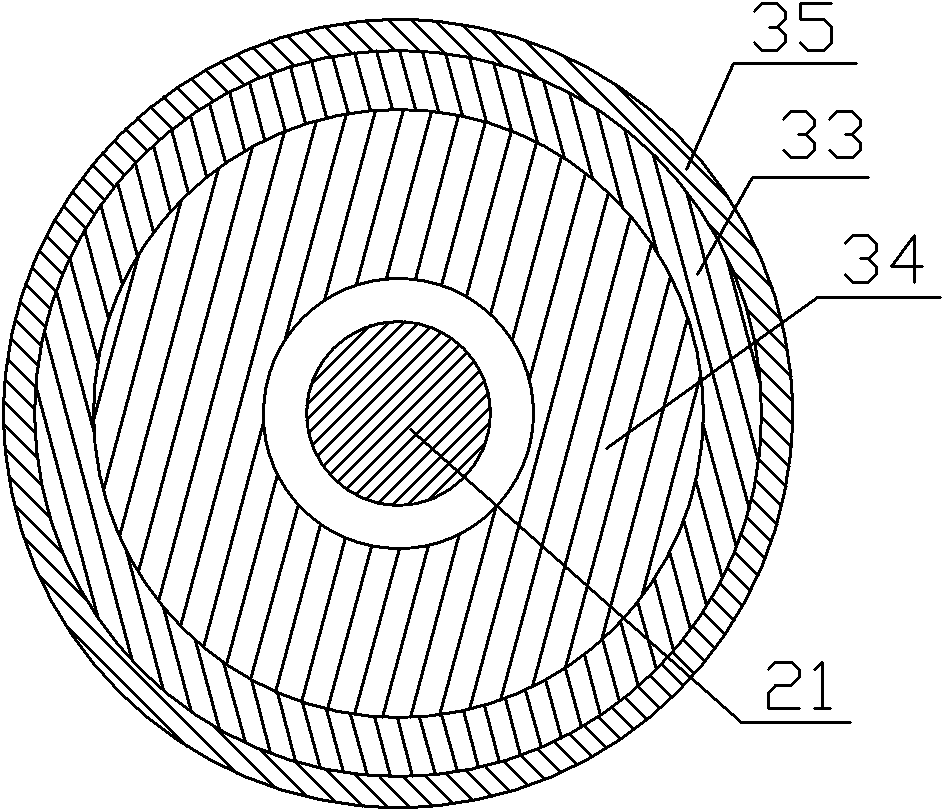

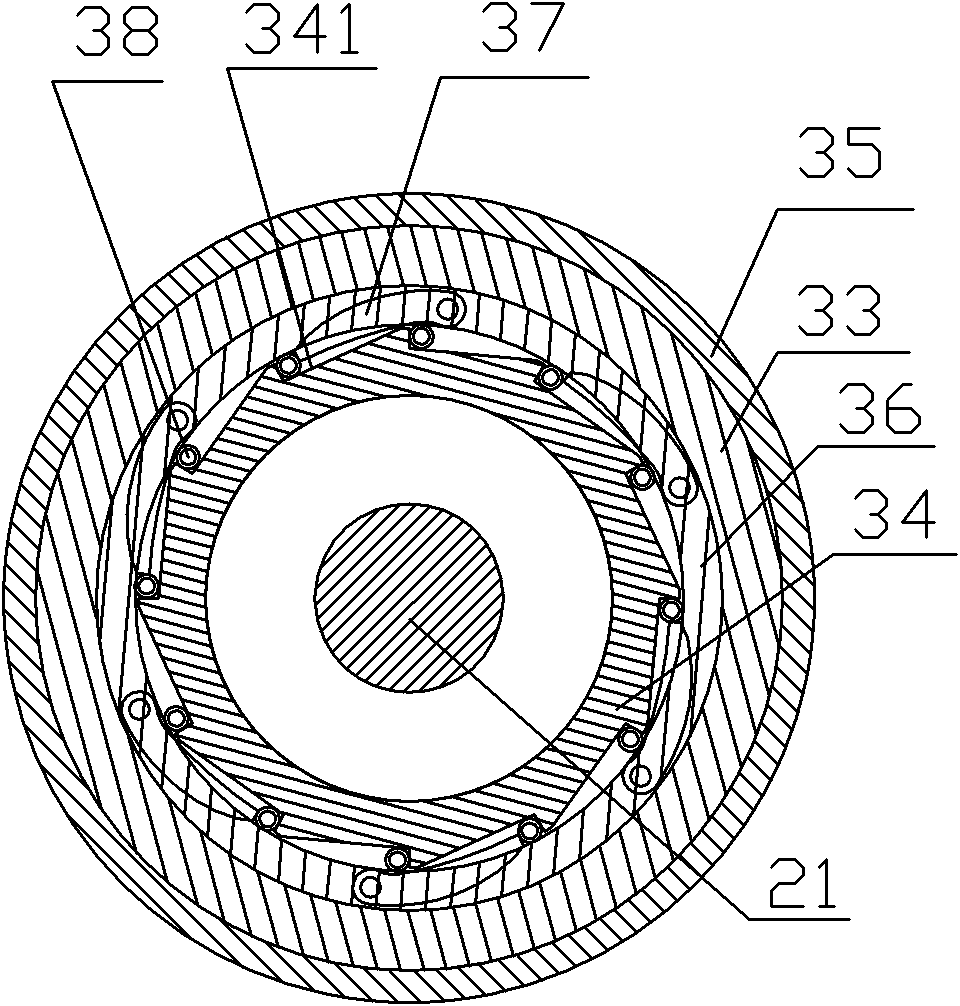

[0073] refer to Figure 1 to Figure 3 As shown in the figure, the tensioning equipment 110 of the concrete bridge of the present invention comprises a jack 10, a tensioning mechanism 20 and a locking mechanism 30, the jack 10 comprises a cylinder 11, a piston 12, an oil return port 13 and an oil inlet 14, and the piston 12 is set in the cylinder body 11. The locking mechanism 30 is arranged on the outside of the cylinder body 11 and is connected with the piston 12. The locking mechanism 30 includes a rotary handle 31, a support plate 32, a support sleeve 33, a rotary sleeve 34 and a rotary outer cover 35, wherein the support sleeve 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com