Construction method and structure for mounting reverse-construction steel pipe column in rotary drilled pile hole

A technology of steel pipe column and rotary excavation pile, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of inability to meet energy saving and emission reduction, large waste, long construction time, etc., and achieves wide practicability and popularization. The effect of speeding up the construction period and efficient construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

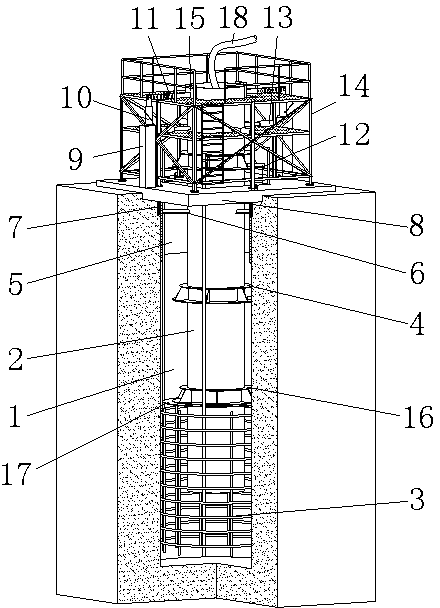

[0031] A construction method for installing upside-down steel pipe columns in rotary excavation pile holes of the present invention, when specifically implemented, as follows figure 1 As shown, follow the steps below for construction:

[0032] Step 1. First determine the hole position of the pile hole 1 on the ground according to the project needs, and then bury the steel casing 5 centered on the hole location. The inner diameter of the steel casing is larger than the hole diameter of the pile hole, and the bottom of the steel casing should extend into the clay layer by more than 0.5m. The length shall meet the requirement that the bottom of the steel casing enters the clay layer not less than 0.5m. A rotary drilling rig is erected above the steel casing. The error between the center of the drill bit of the rotary drilling rig and the center of the pile position is not more than 10 mm, and the diameter of the drill bit is 2.2 meters. After the pile hole 1 was drilled, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com