Bored pile pore-forming quality detecting device and method

A quality detection method and detection device technology, applied in the direction of measuring devices, surveying, earthwork drilling and mining, etc., can solve problems such as difficult quality control, collapsed holes, and reduced bearing capacity of the whole pile, so as to avoid uneven building decline and detection Complete functions, improve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

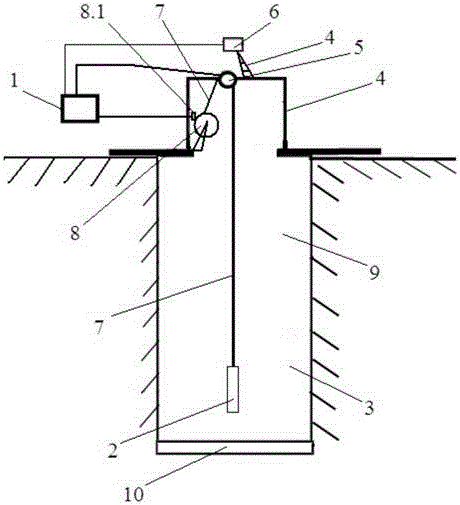

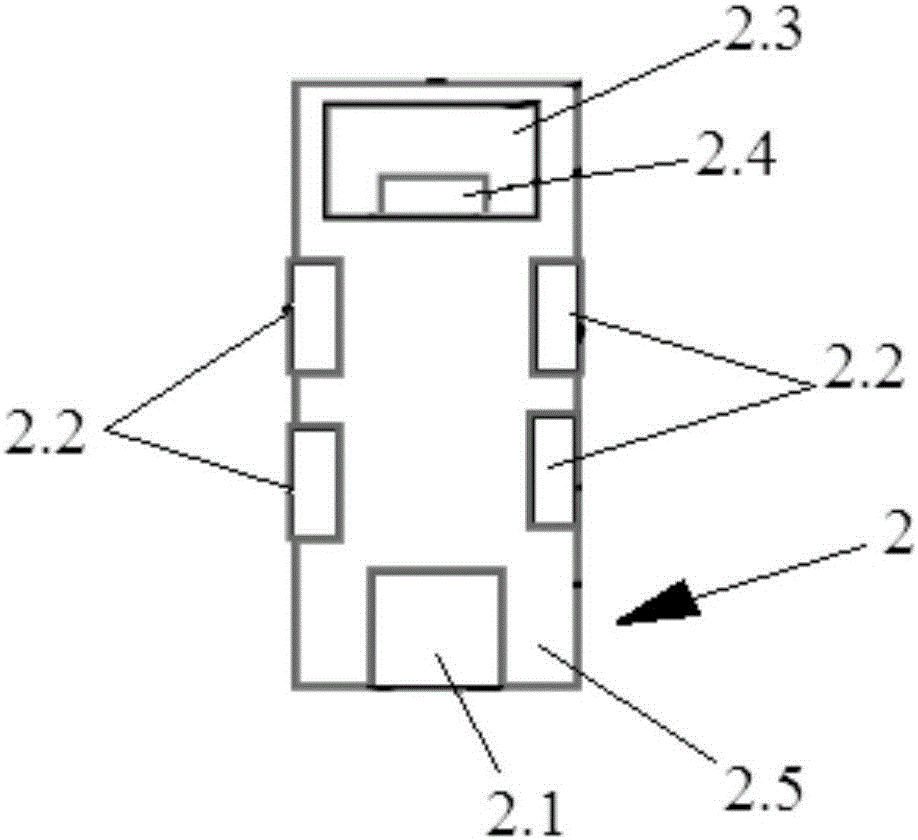

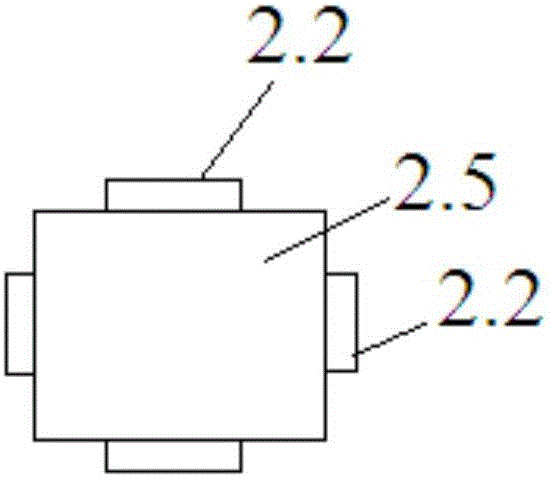

[0027] A kind of bored pile hole-forming quality detection device of the present invention, such as Figure 1~4 As shown, it includes a hole-forming detection host 1, a probe 2, a wire frame 4, a depth counting pulley 5, a GPS sensor 6, a cable bus 7, and a reel 8. The probe 2 includes a probe housing 2.5, which is installed on the probe The fluid density sensor 2.1 at the bottom of the housing 2.5, the ultrasonic transmitting and receiving sensor 2.2 installed on the side wall of the probe housing 2.5, the circuit cavity 2.3 arranged on the upper part of the probe housing 2.5, and the three-dimensional attitude sensor 2.4 installed in the circuit cavity 2.3; The wire frame 4 is erected at the hole of the pile, and the wire frame 4 is installed with a take-up and pay-off reel 8, a depth counting pulley 5, and a GPS sensor 6; the fluid density si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com