Composite heat preserving template and building main body integrated construction heat preserving system

A technology of composite thermal insulation and building main body, applied in thermal insulation, construction, building components and other directions, can solve the problems of difficult to control the thickness of thermal insulation layer, difficult to control construction quality, and many gaps in thermal insulation blocks, so as to reduce one-time construction investment and cost. The effect of low and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

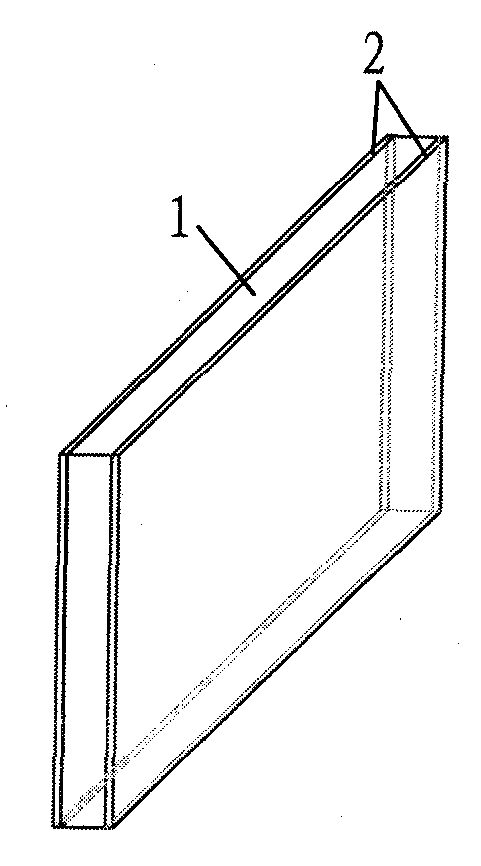

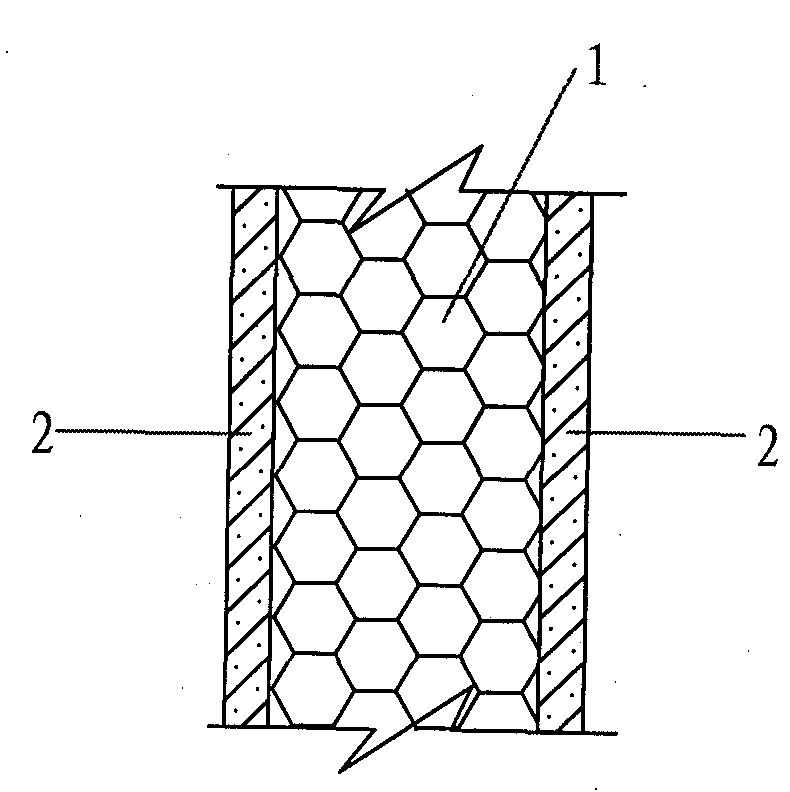

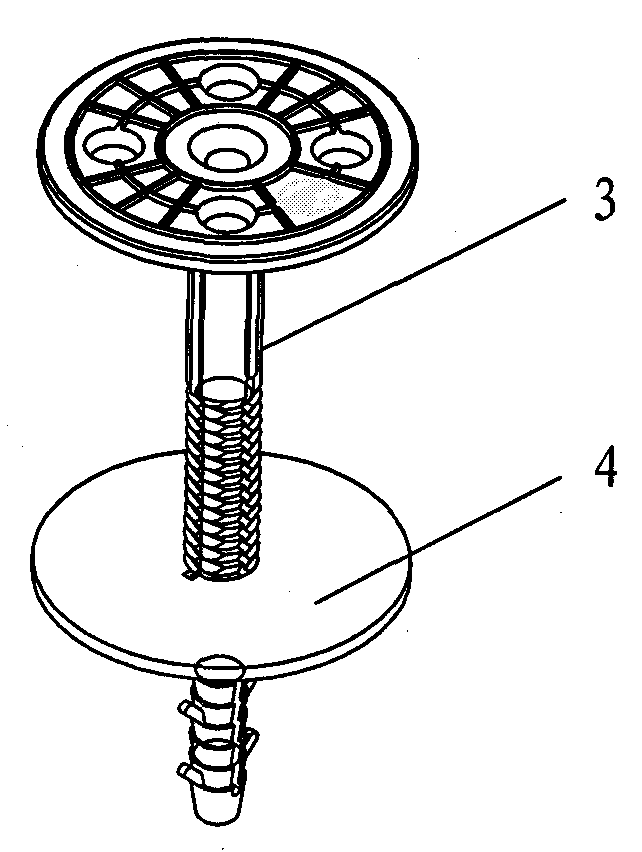

[0057] Example 1: see figure 1 , Figure 1a , figure 2 , Figure 2a , image 3 , Figure 4 , Figure 4a , according to the thickness of the insulation layer designed by the construction project, the inner and outer panels 2 are bonded to the insulation layer 1 in the factory to form a composite insulation formwork composed of the insulation layer 1 and the inner and outer panels 2; the plastic bolt body 3, belt The lock nut 4 of the disk, the L-shaped adapter 5, and the special drill bit have been processed; Inverted tooth buckle, 4 sets of locking nuts with discs can not be returned when pulled forward on the bolt rod; special drill bits include drill rod 16, alloy milling cutter 17, drill body disc 18, jacking screw 19, drill Both the rod 16 and the alloy milling cutter 17 are fixed on the drill body disk 18, and the jacking screw 19 tightens the tail end of the drill rod 16 to fix the drill rod on the drill body disk; the quality of.

[0058] Concrete part construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com