Locking system for air intake structure for turbojet engine nacelle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

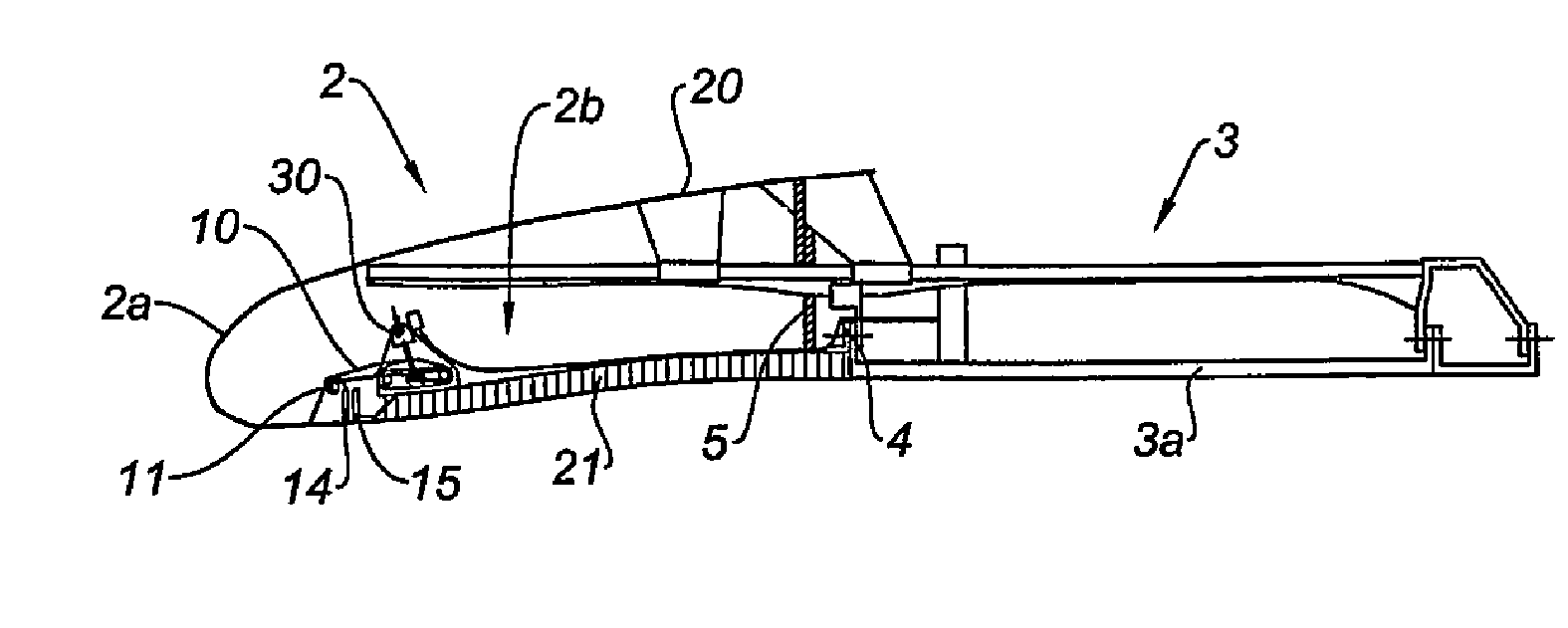

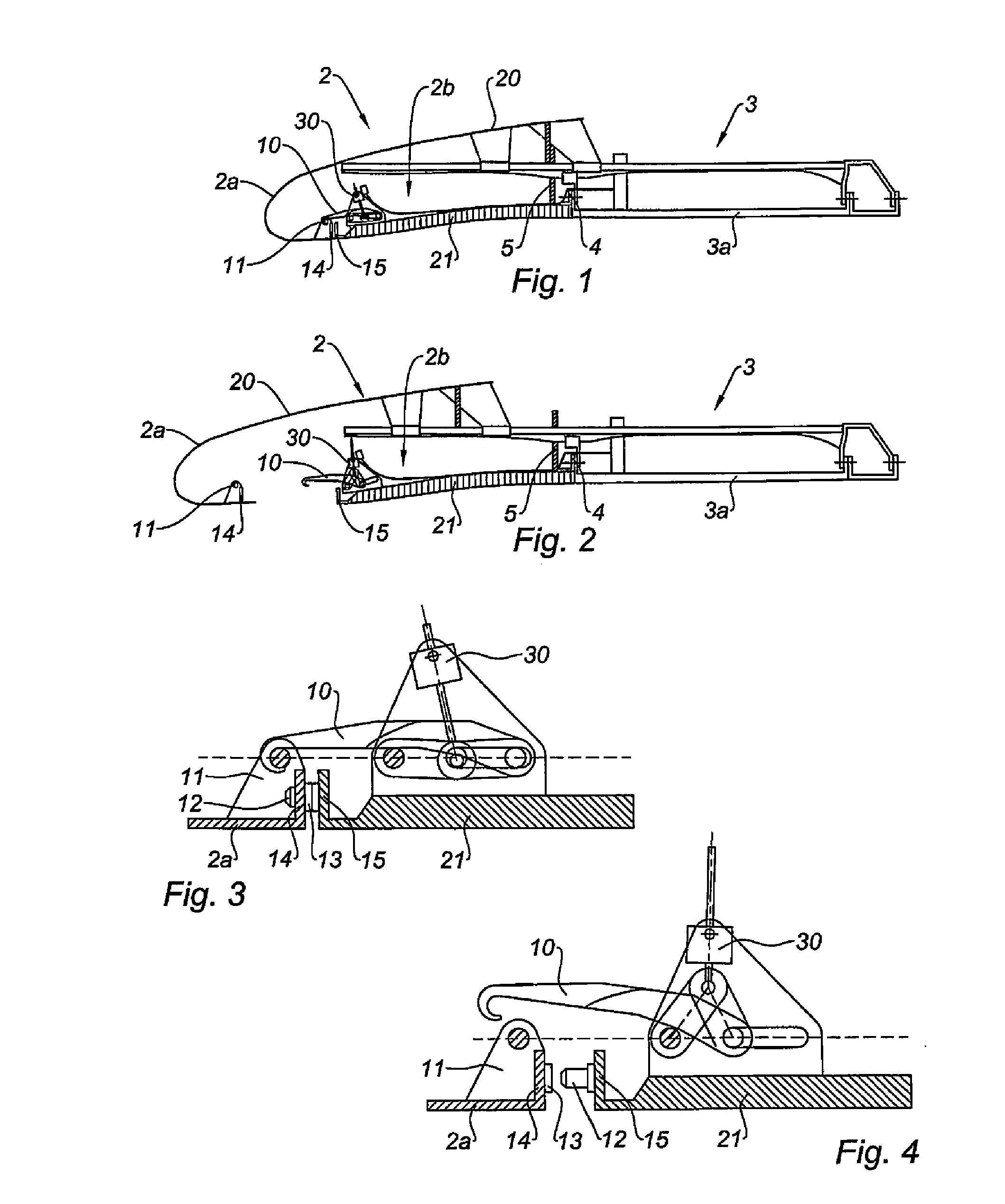

Image

Examples

second embodiment

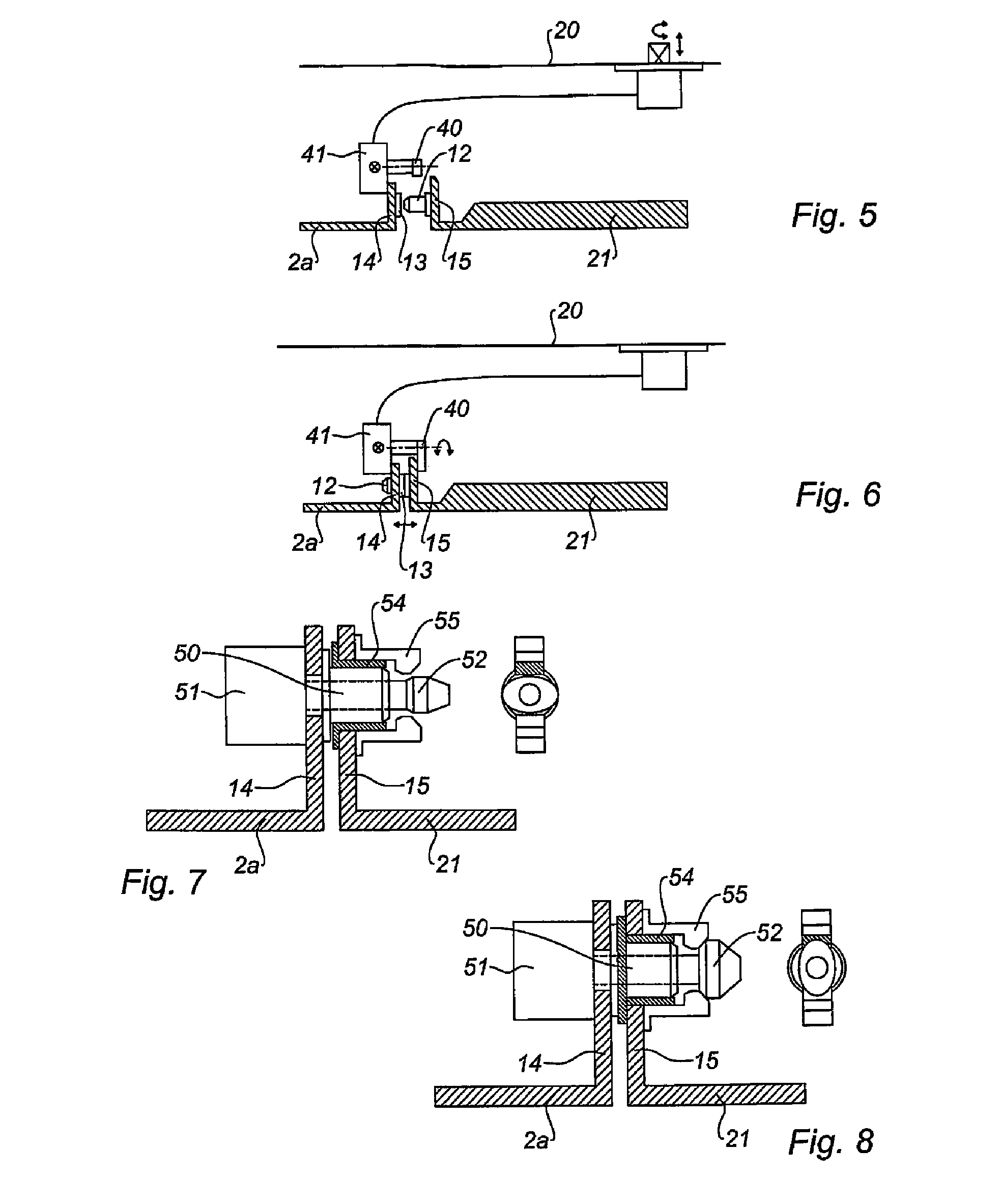

[0068]FIGS. 5 and 6 present the locking comprising a rotating hook 40 driven by an electric motor 41 capable of engaging with the return 15 of the inner panel 21, which then serves as complementary retaining means.

[0069]The centering pins can also be used directly in the locking means.

third embodiment

[0070]Thus, FIGS. 7 and 8 show a third embodiment in which the centering pin 50 is passed through by a blocking cam 52 capable of being driven in rotation by an electric motor 51 supported by the return 14 of the air intake structure 2a.

[0071]The pin 50 is capable of cooperating with a bore 54 formed in the return 15 of the inner panel 21.

[0072]The return 21 also supports retaining means 55 of the cam 52 designed such that said cam 52 has an unblocking position in which it can be removed from the retaining means 55 through the bore 54 and a blocking position in which it abuts against the retaining means 55, which then prevent its removal.

[0073]Of course, the cam 52 can be an integral part of the pin 50, which is then itself driven in rotation. Advantageously, the pin shall, however, be kept fixed in rotation.

[0074]FIGS. 9 and 10 present a screw locking system.

[0075]To do this, the return 15 of the inner panel 21 supports a threaded centering pin 60 capable of being driven in rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com