Method for carrying out construction in vertical shaft or inclined shaft through raise boring machine

A technology of a raise drilling rig and construction method, which is applied in drilling equipment and methods, drilling equipment, directional drilling and other directions, can solve the problems of high safety risks, twisted and broken drill pipes, and high deflection rate of pilot holes, and achieves increased economic benefits, The effect of speeding up the construction progress and ensuring the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

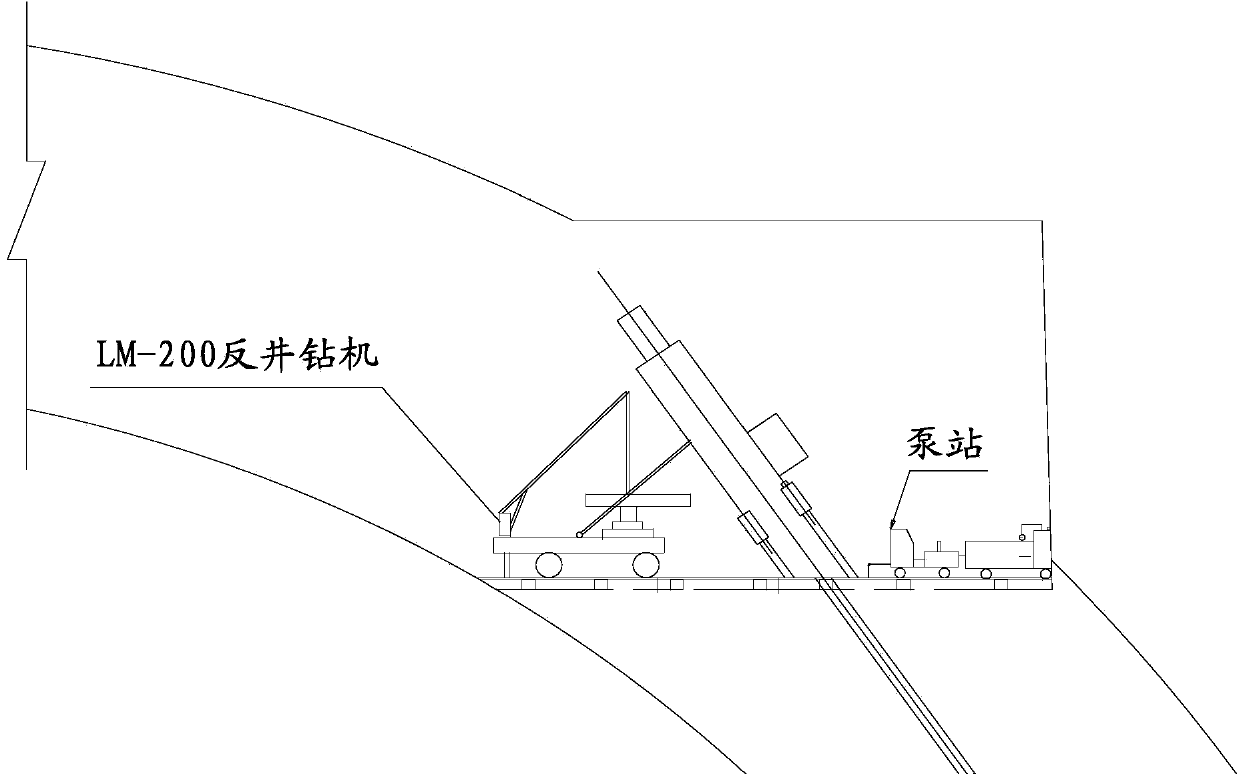

[0057] A method of using a raise drilling rig in underground well construction. The method uses the raising drilling rig to complete the construction of the guide well in the inclined well section. Drill a pilot hole with a diameter of Ф216mm in the downward direction. After the pilot hole is formed, replace the Ф216mm drill bit with a Ф1400mm expansion cutter in the downward bending section, and then form a slag guide well with a diameter of Ф1400mm by reverse pulling and expanding from bottom to top. The construction process is as follows:

[0058] Expansion and support of the upper bend section → construction of foundation and circulating water pool → cooling circulating water pool → installation and commissioning of raise drilling rig → pilot hole construction → reaming construction → drilling rig removal. The specific process of raising drilling rig construction is as follows:

[0059] 1. Pilot hole construction using Ф216mm pilot hole drill bit:

[0060] (1) The key to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com