Steel cable stretching force detecting apparatus

A technology of tension detection and wire rope, which is applied in the field of tension measurement of belts or similar flexible elements, cables, wires, and ropes. It can solve the problems of many times of force conversion, the impact of bending deformation stress on inspection accuracy, and the inability to perform unified calibration, etc., to achieve Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

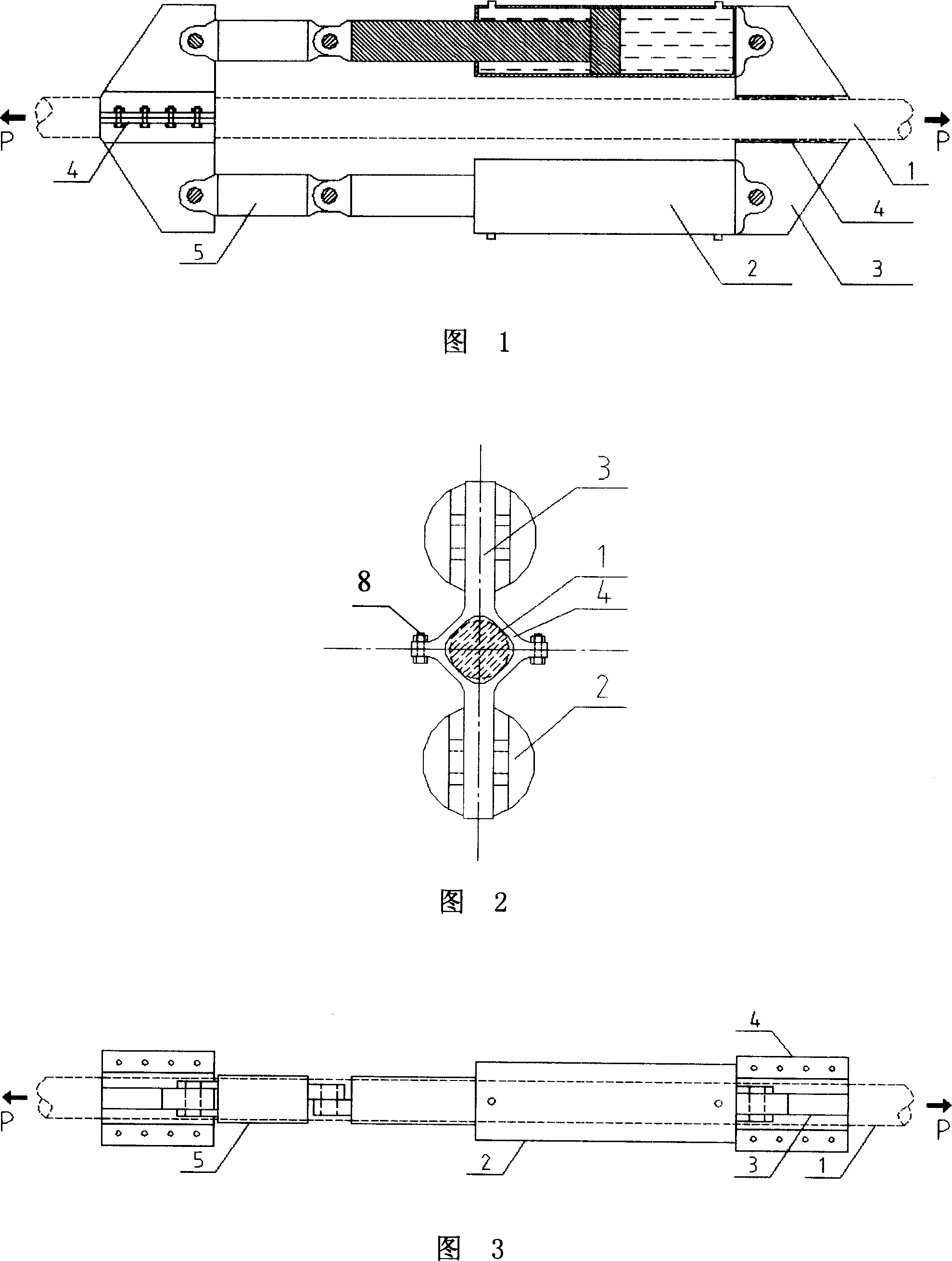

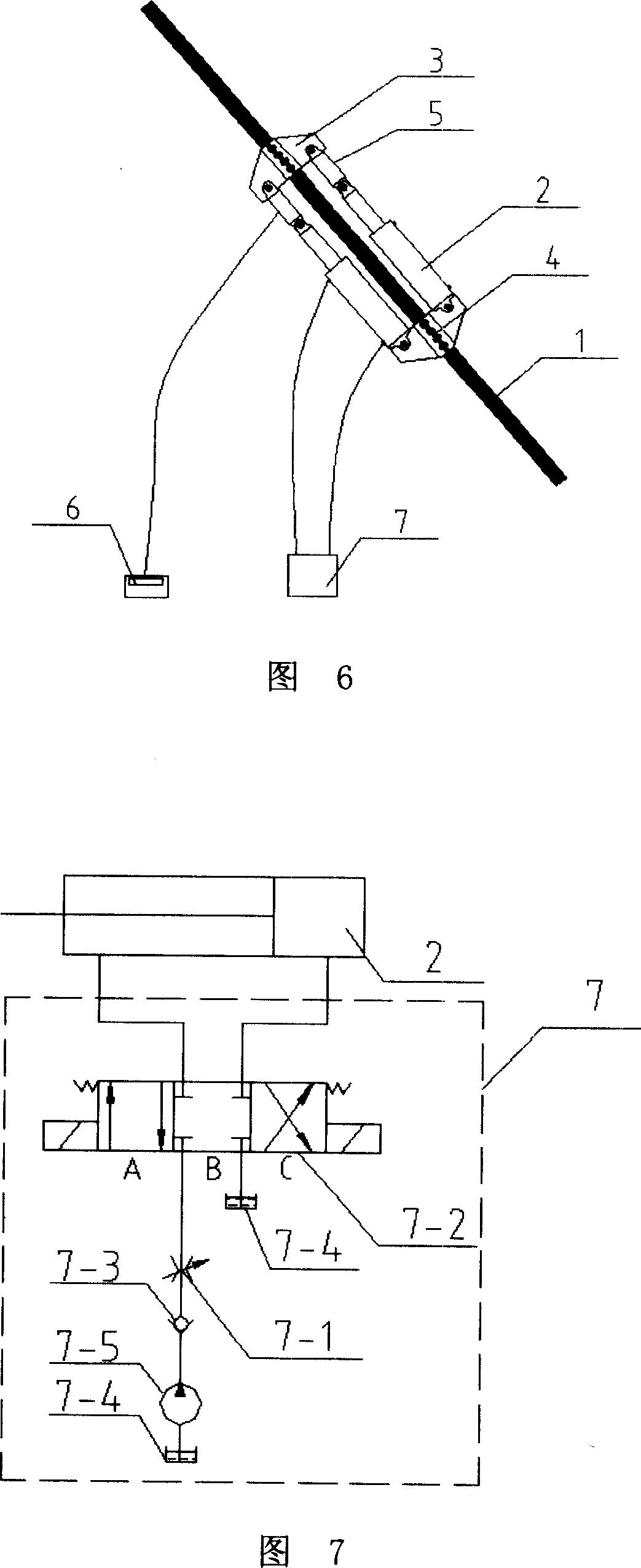

[0019] Referring to Fig. 1, the whole device of the present invention will be composed of two cable clamps 4, two ZQ-280 / 160×1100S2 type high-pressure oil cylinders 2 and two LGJ type tension sensors 5 to form a four-bar frame structure hinged to each other, wherein the two cable clamps 4. Two rods are formed, and the rods on both sides are respectively composed of a ZQ-280 / 160×1100S2 type high-pressure oil cylinder 2 and a -LGJ type tension sensor 5 hinged.

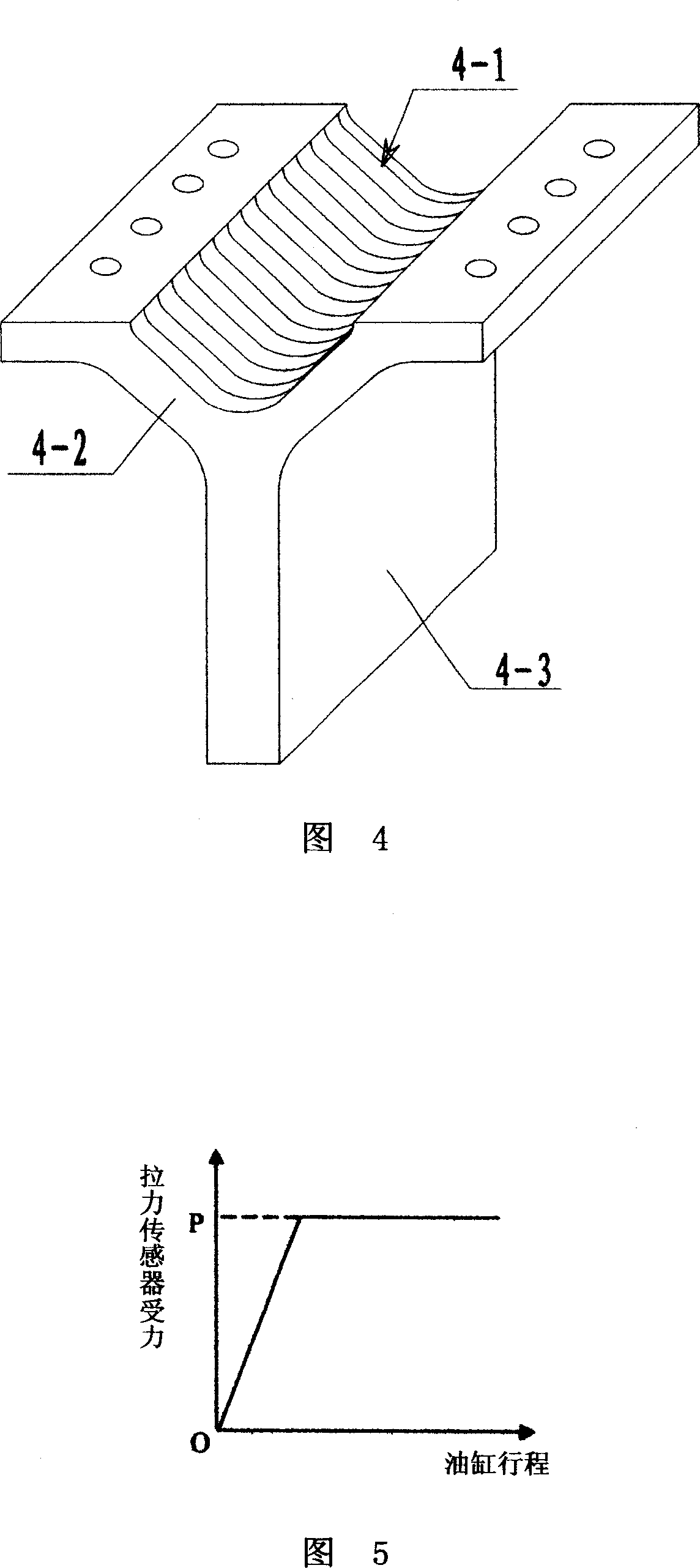

[0020] Referring to Fig. 1, Fig. 2 and Fig. 3, the clamp body of the cable clamp 4 is half-shaped, each side is fixedly connected by 4 screws 8, and the clamping cable hole 4-1 is set on the half parting surface , the outer wall of the clamp body 4-2 respectively extends a wing plate 4-3 to both sides. The clamping steel cable hole 4-1 in the clamping body 4-2 is a quadrangular shape (see Figure 3), which can clamp steel cables 1 of different diameters and also play a role of self-centering clamping; The inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com