Longitudinal integration system and method for quality management

A quality management, vertical technology, applied in data processing applications, instruments, resources, etc., can solve problems such as unfavorable product quality status, untraceable supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

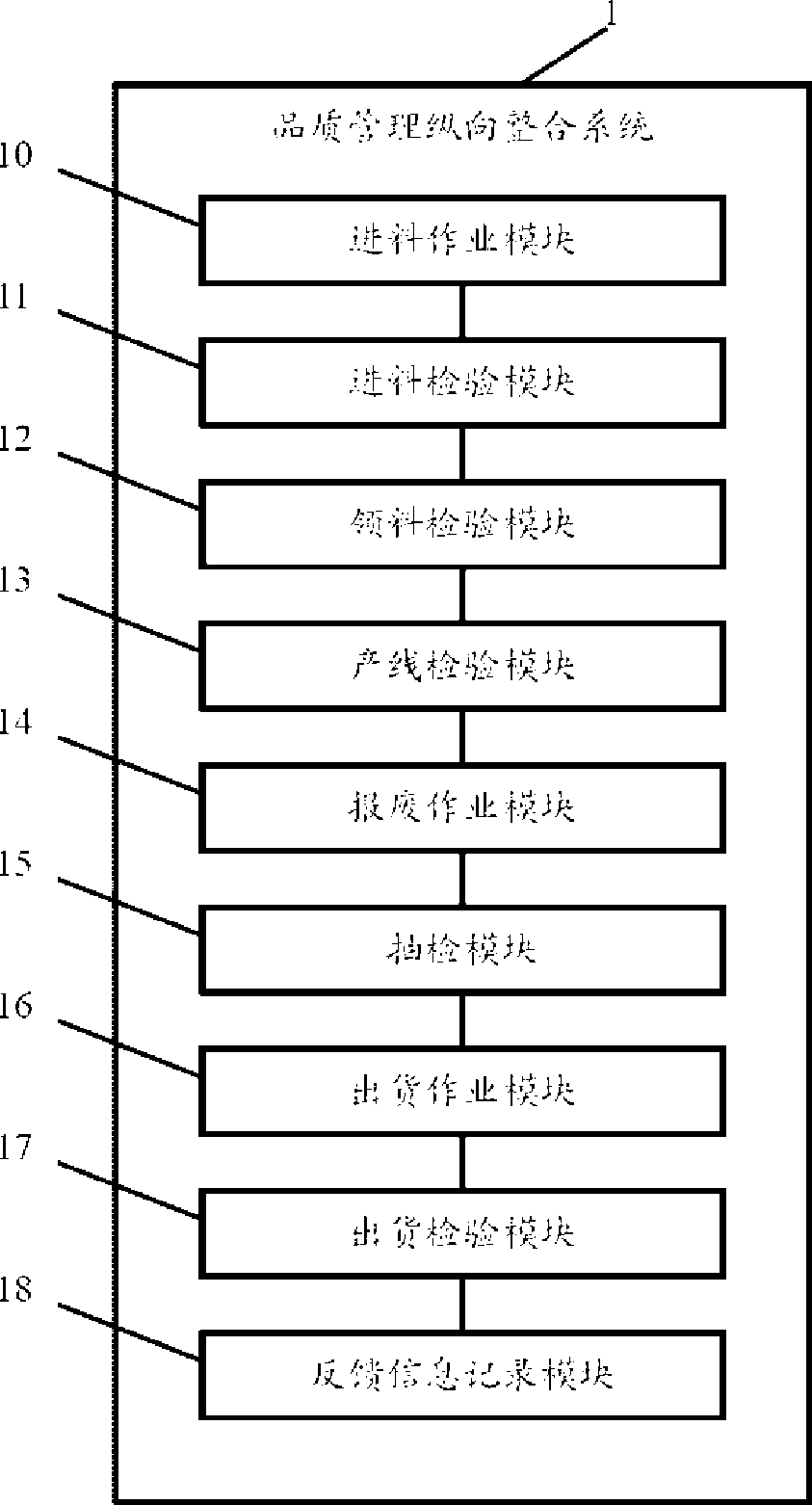

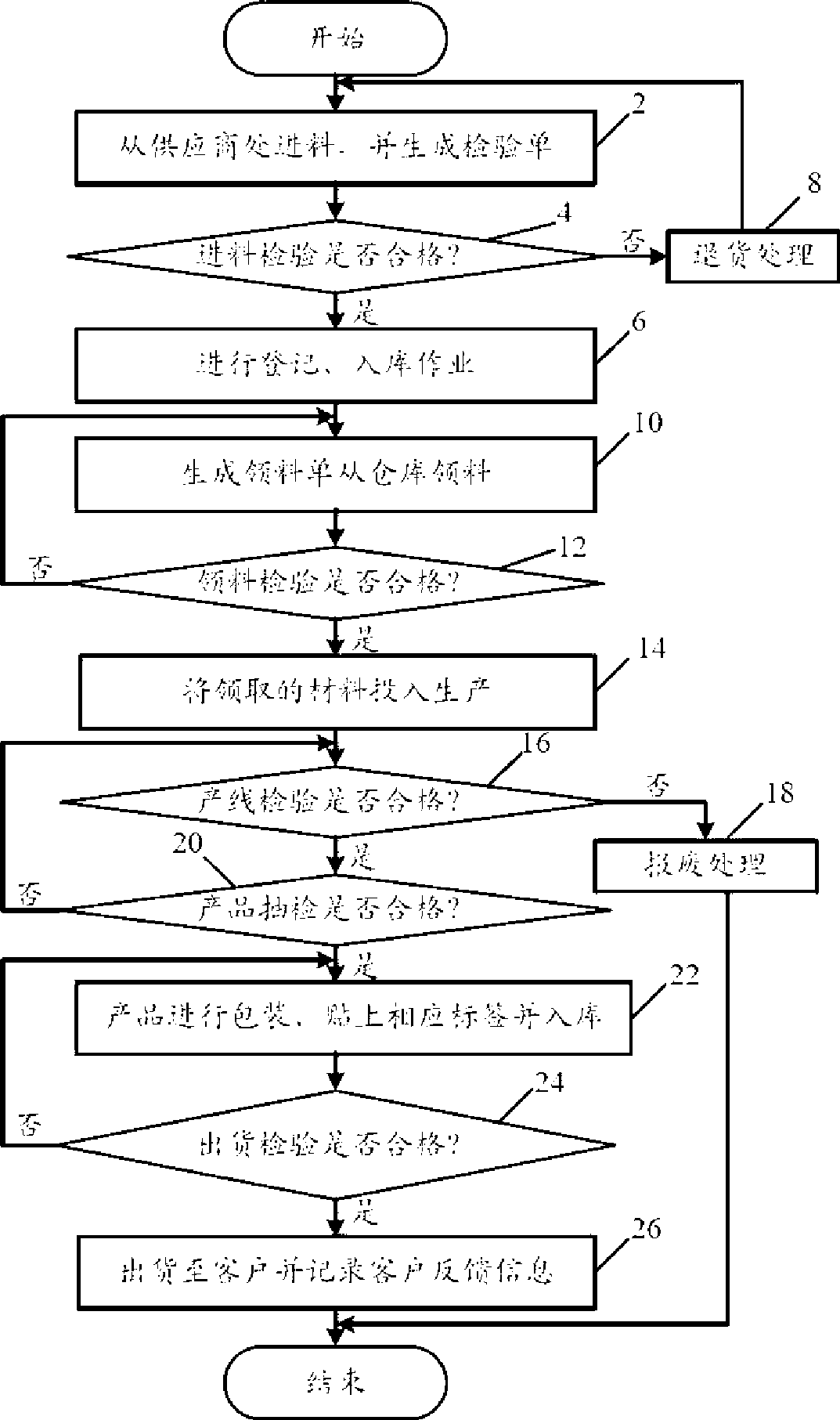

[0011] refer to figure 1 Shown is a functional block diagram of the quality management vertical integration system of the present invention. The quality management vertical integration system 1 of the present invention (hereinafter referred to as "this system 1") is used to vertically integrate the quality inspection of raw materials, finished products, and semi-finished products in different stages such as raw material purchase, production, and product shipment. This system 1 mainly includes: incoming material operation module 10, incoming material inspection module 11, material receiving inspection module 12, production line inspection module 13, scrapping operation module 14, sampling inspection module 15, shipping operation module 16, and shipping inspection module 17 And the feedback information recording module 18.

[0012] The material feeding operation module 10 is used to purchase raw materials from suppliers according to orders, and generate corresponding inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com