Quality traceability analysis method of whole process product based on process rules and big data

A product quality and analysis method technology, applied in the field of whole process traceability, can solve problems such as inability to guarantee full traceability of product quality information, omission of important information in the production process, etc., to achieve the effects of improving evaluation effectiveness, optimizing sampling, and improving analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

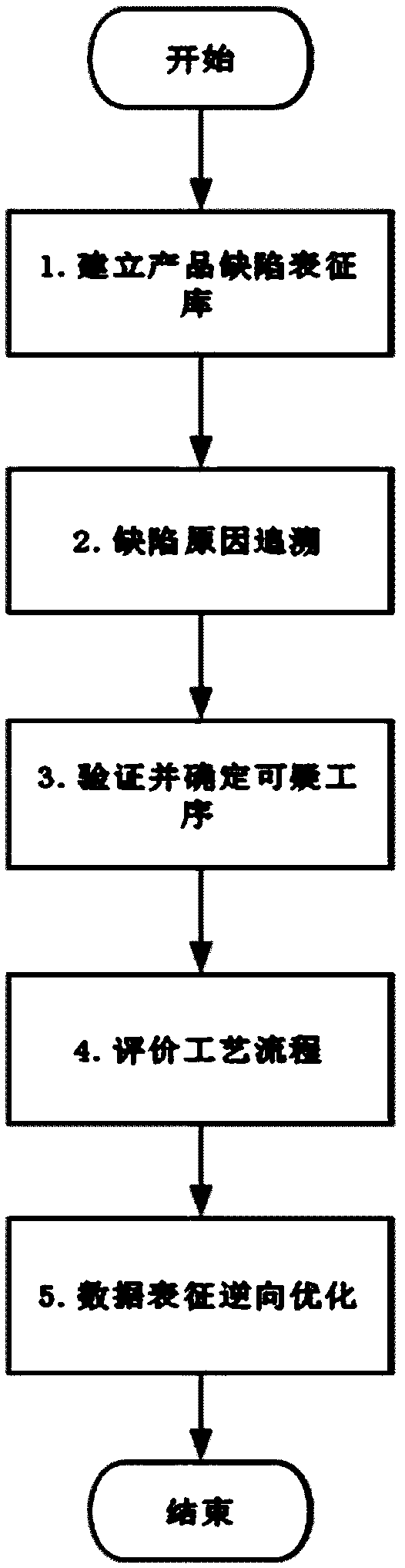

[0026] Example figure 1 As shown, the whole-process product quality traceability analysis method specifically includes the following steps:

[0027] 1. Establish a product defect characterization library: This process requires manual conversion of a large amount of image data collected by the sensor into corresponding text defect features, which are stored in the relational database MySql to realize simple query and processing functions. If there are only text defect features also can.

[0028] The product defect characterization library at this time is only preliminary, and will be supplemented in later steps.

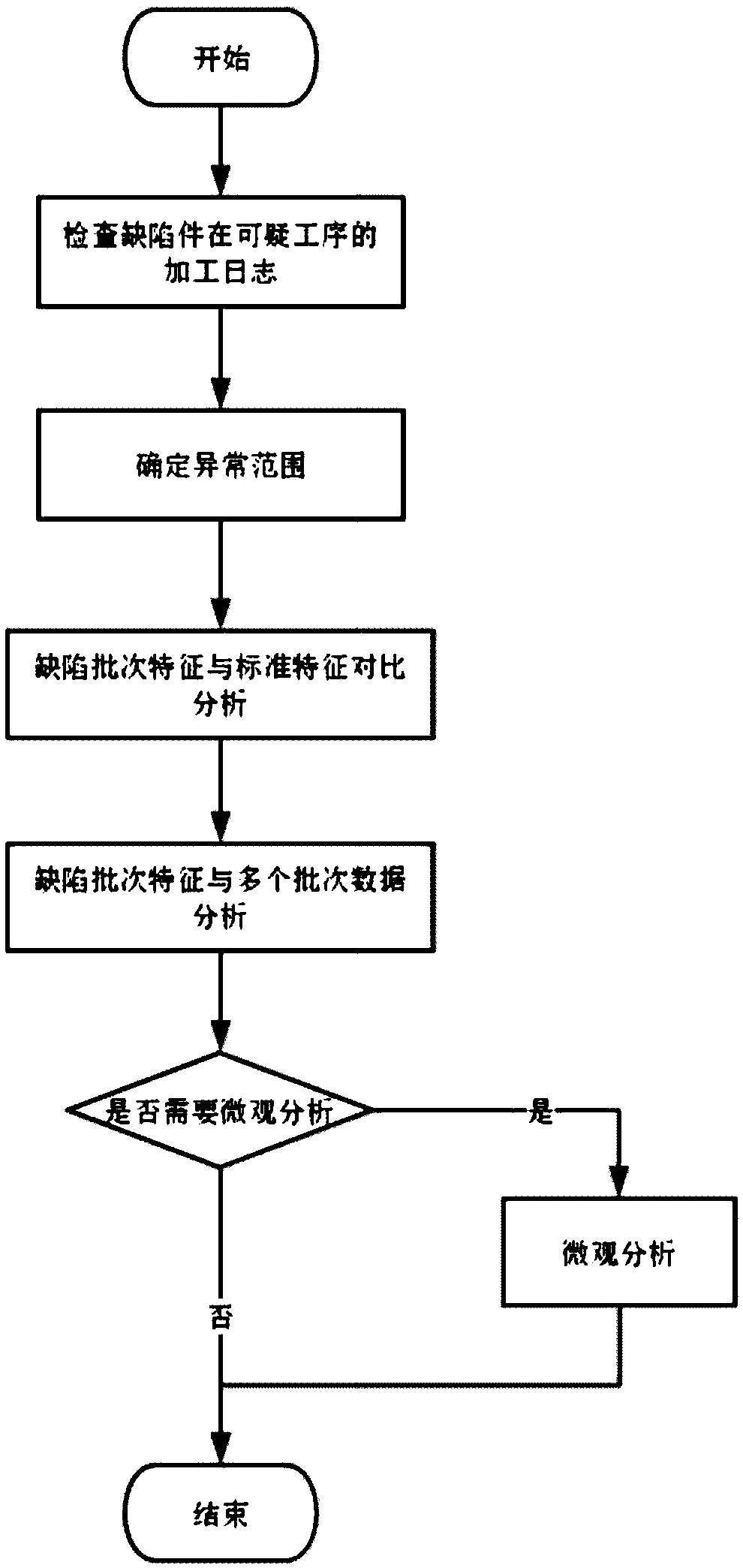

[0029] 2. Defect cause tracing: On the basis of the existing product defect characterization database built in step 1, for a new defective individual, first use MySql query statement to query whether there is the same type of defe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com