Quality management method for production workshop

A quality management and production workshop technology, applied in the field of clothing industry, can solve problems such as inability to manage product quality, restrict enterprise development, and low product quality, achieve real-time monitoring, reduce communication, and have strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

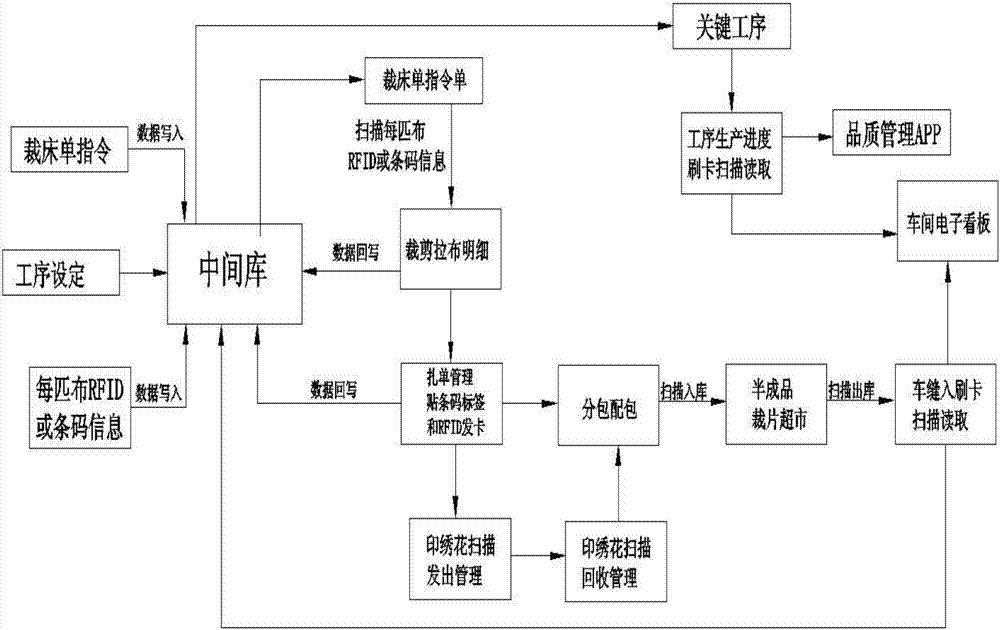

[0018] as attached figure 1 The quality management method of a kind of production workshop described in the present invention as shown, comprises the following steps:

[0019] The first step is to write the cutting sheet instruction, each piece of cloth RFID or barcode information, and the relevant data of the process setting into the intermediate warehouse for confirmation. The intermediate warehouse generates the cutting sheet instruction sheet and captures the key processes in the process setting ;

[0020] In the second step, after scanning the RFID or barcode label of each piece of cloth to be cut, the cutting cloth details are automatically generated, and at the same time, the corresponding cutting cloth details are written back to the intermediate library;

[0021] The third step is to manage the cut pieces after cutting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com