On-line monitoring method for cutter abrasion damage based on main shaft driving current and working step.

A technology of spindle drive and tool wear, which is applied in the field of on-line monitoring of tool wear and damage of CNC machine tools and on-line monitoring of tool wear and damage. It can solve problems such as changing machine tools, affecting normal processing, and poor applicability, so as to reduce tool use costs and workpieces. Scrap rate and machine tool failure rate, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

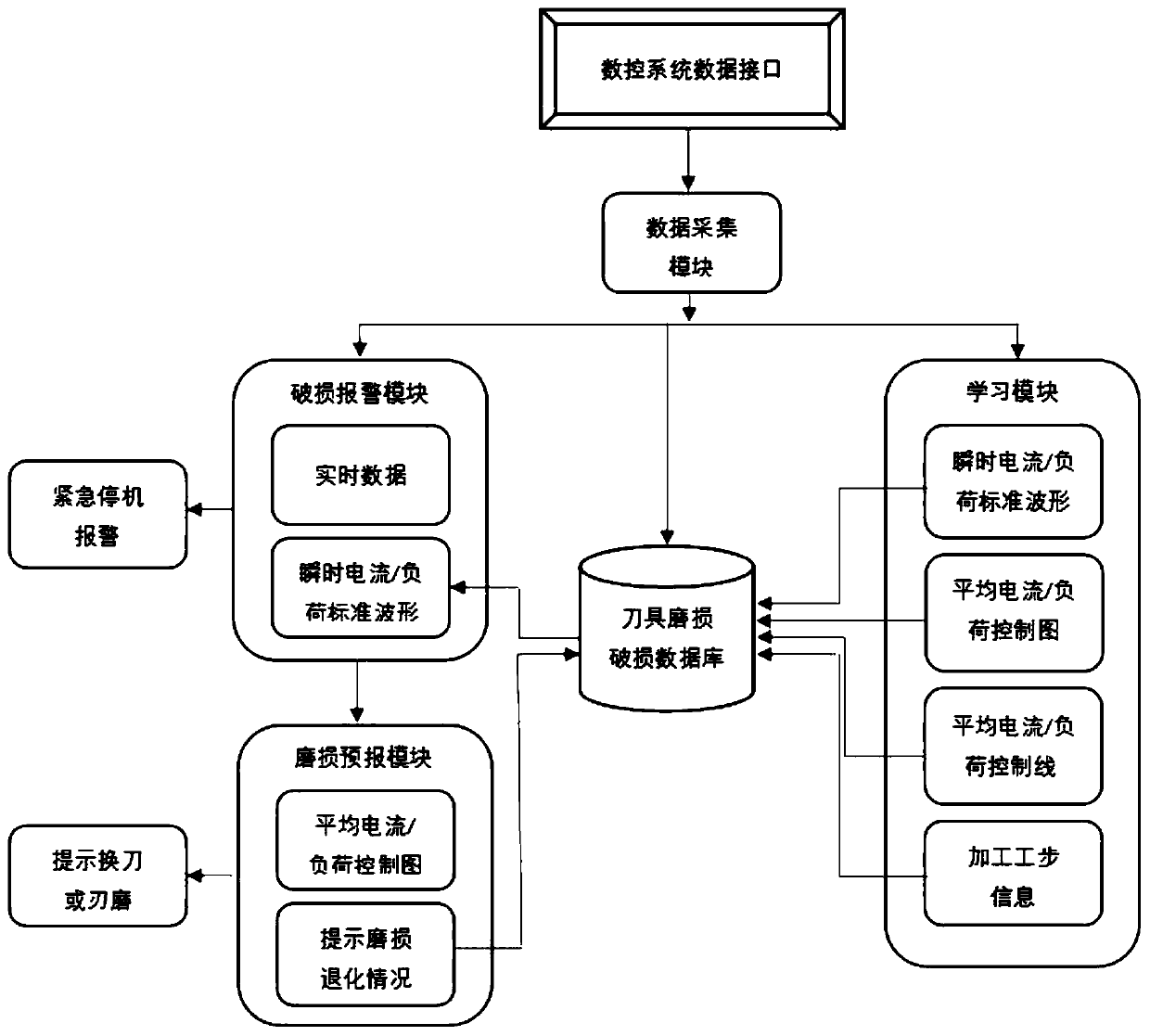

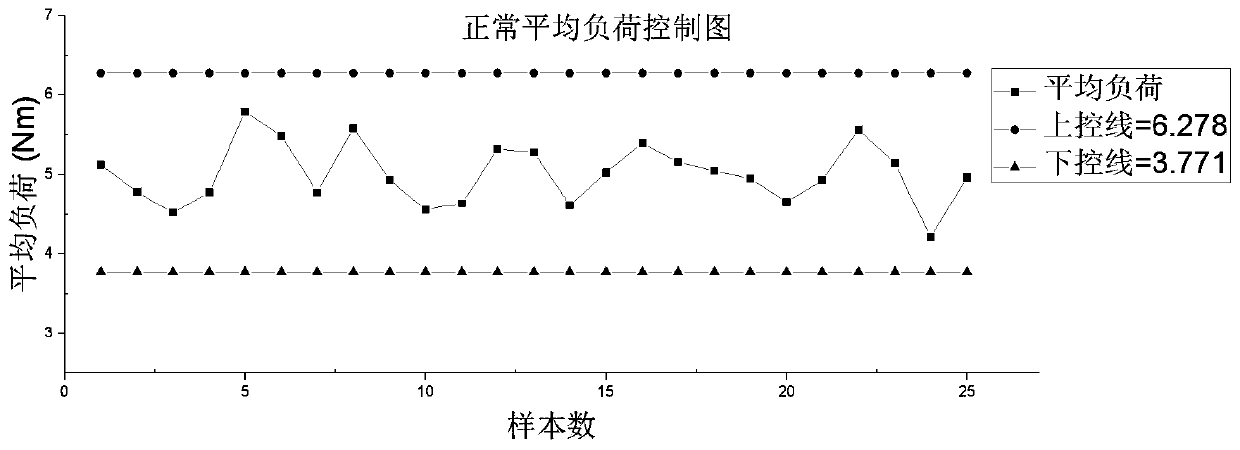

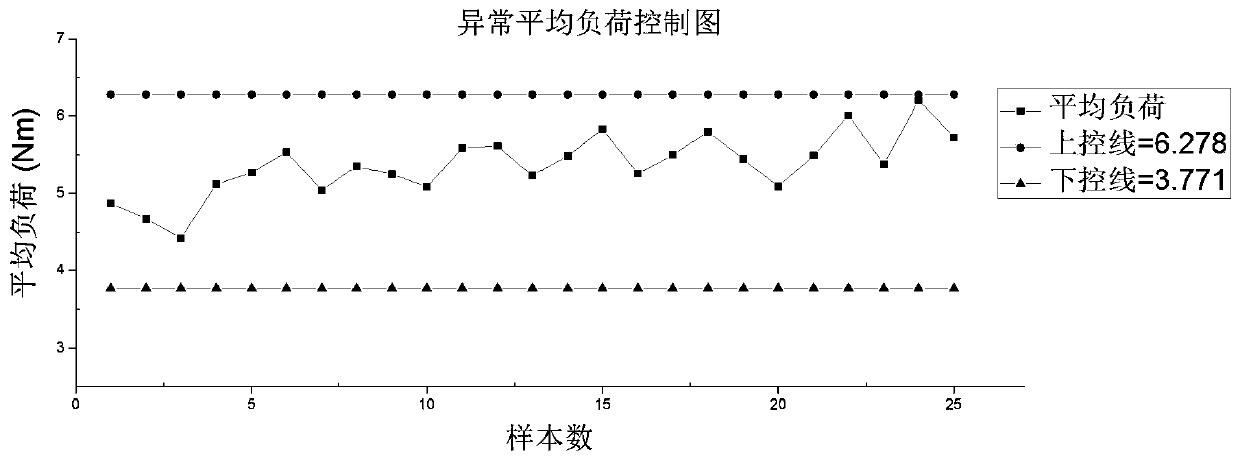

[0019] The monitoring system provided by the present invention obtains the spindle drive current / load and processing step information through the data interface of the numerical control system, and after averaging and eliminating random errors, it fits the standard waveform curve of the instantaneous current / load changing with the processing time during the normal processing of the working step . During the machining process of CNC machine tools, the instantaneous current / load is monitored and compared with the standard curve. When it is judged that the tool is damaged, an alarm signal is sent to trigger the emergency shutdown protection of the machine tool. In addition, after the machining of the workpiece, create an average current / load average control chart and analyze the wear state of the tool, and dynamically adjust the tool change or sharpening rules of the machining tool.

[0020] The on-line monitoring method of tool wear and damage based on spindle drive current and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com