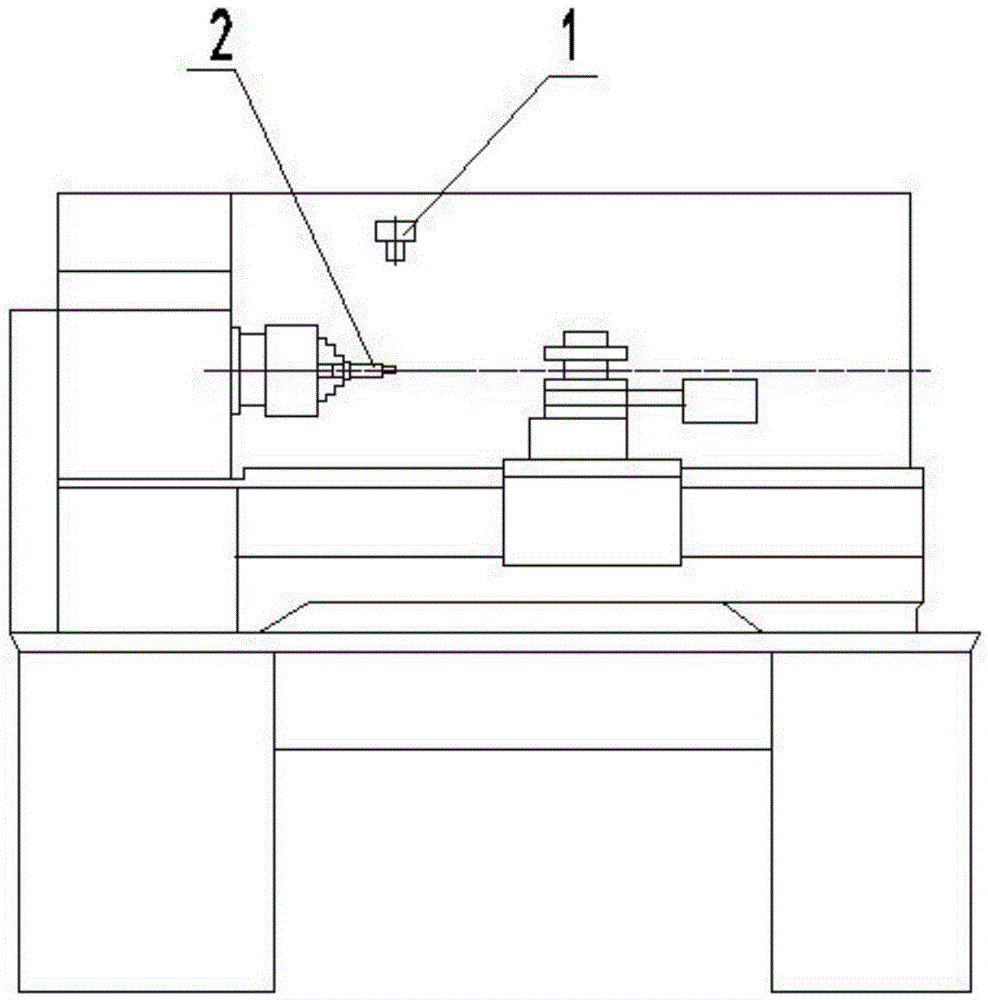

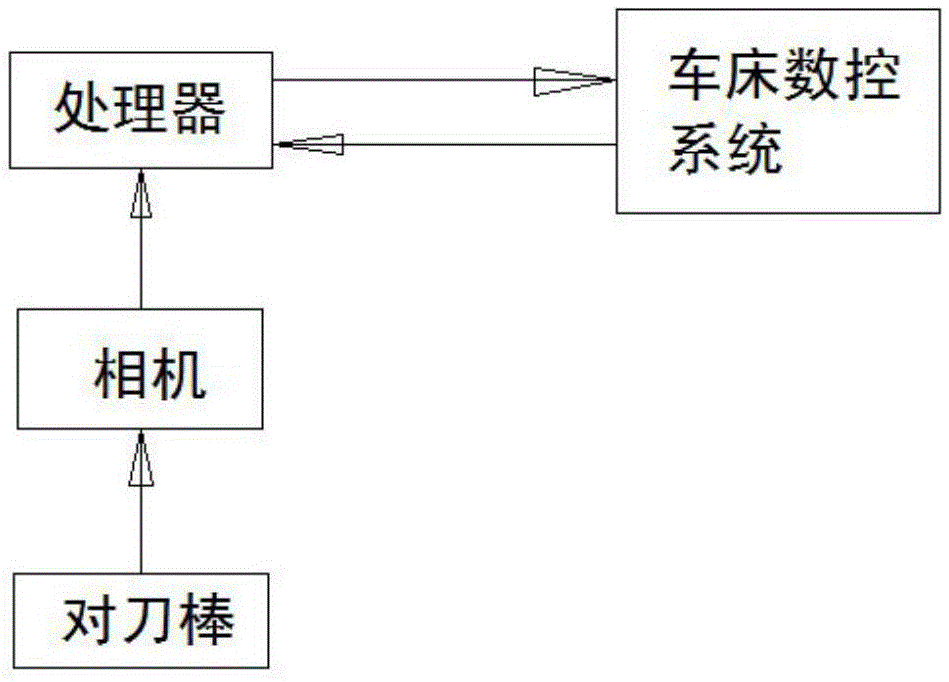

A tool setting device and method for CNC lathe based on machine vision

A CNC lathe and machine vision technology, applied in auxiliary devices, turning equipment, accessories of tool holders, etc., can solve the problems of high technical level and work emotion dependence, low tool setting accuracy, and high cost, and avoid unnecessary loss, high work efficiency, and the effect of preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

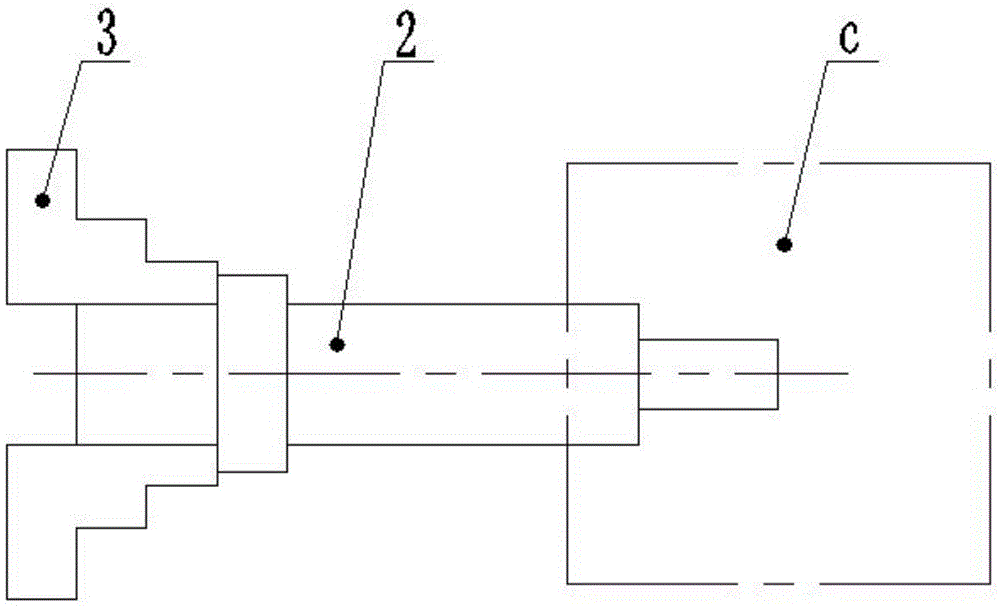

[0040] Such as Figure 7 Shown: During the machining process, install a turning tool detection camera 5 in an open area that does not interfere with the workpiece fixture on the CNC lathe, which can be used to detect the wear and damage of the turning tool, as well as the tool offset value of the replaced tool during the machining process Determination. Turning tool detection camera 5 is installed in the rear top in the nacelle. Install the turning tool detection camera 5 according to the aforementioned method and perform dimensional accuracy calibration on the turning tool detection camera 5 .

[0041] Before the processing starts, the program can be used to control the movement of each tool including the reference tool into the field of view of the turning tool detection camera 5, collect the initial digital image of each tool, and record information such as mechanical coordinates; Control the moving tool to enter the field of view of the turning tool detection camera 5, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com