On-line monitoring method of tool wear and damage based on spindle drive current and working steps

A spindle drive and tool wear technology is applied in the field of online monitoring of tool wear and damage and online monitoring of tool wear and damage status of CNC machine tools. Longevity, the effect of reducing the rate of workpiece rejection and machine failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

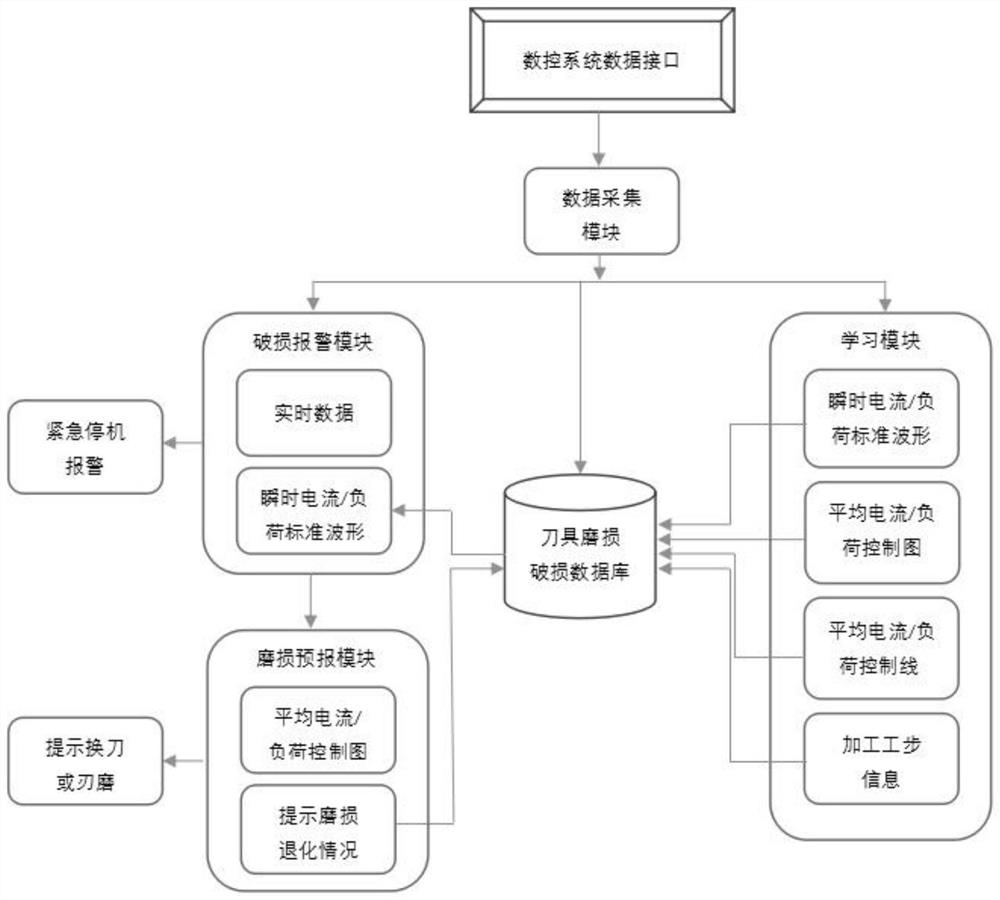

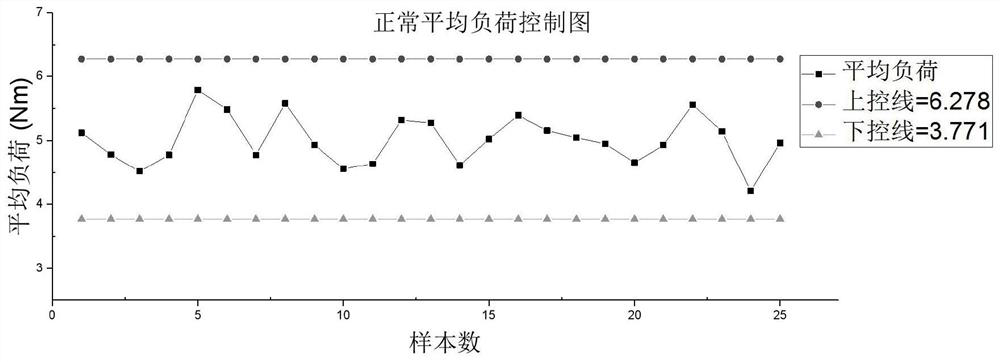

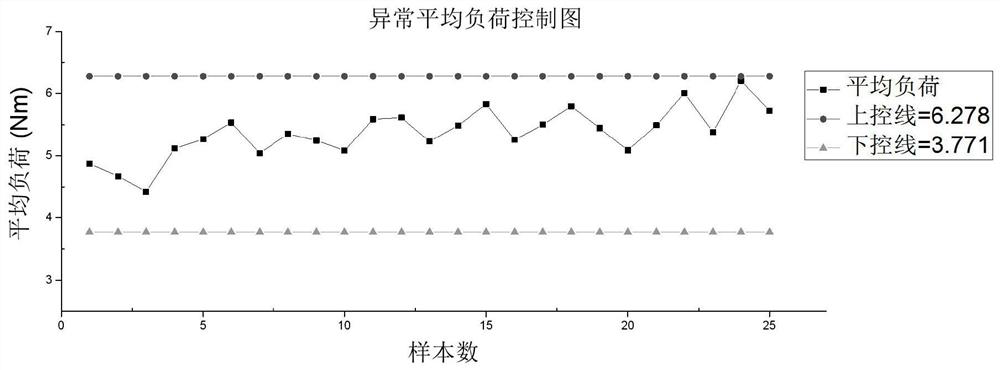

[0019] The monitoring system provided by the present invention acquires the spindle driving current / load, processing step information through the CNC system data interface, and the standard waveform curve of the transient current / load with machining time during normal processing process is equipped with average elimination of random errors. . Monitor the instantaneous current / load during the machining process of CNC machinery and compare the standard curve, and the alarm signal trigger machine emergency shutdown protection is issued when the tool is determined. In addition, the workpiece is finished after the workpiece is finished, and the tool wear is analyzed, and the tool wear condition is dynamically adjusted, and the machining tool is changed or the blade rule.

[0020] Based on the main shaft drive current and the step of cutting on the wire monitoring method, for the batch processing mechanical parts, simultaneously monitor the machining information and spindle curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com