A blast furnace molten iron quality monitoring method based on KPLS robustness reconstruction error

A technology for reconstructing errors and blast furnace molten iron, which is applied in the directions of instruments, adaptive control, control/regulation systems, etc., can solve problems such as difficulty in fault identification, and achieve the effect of ensuring the quality of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

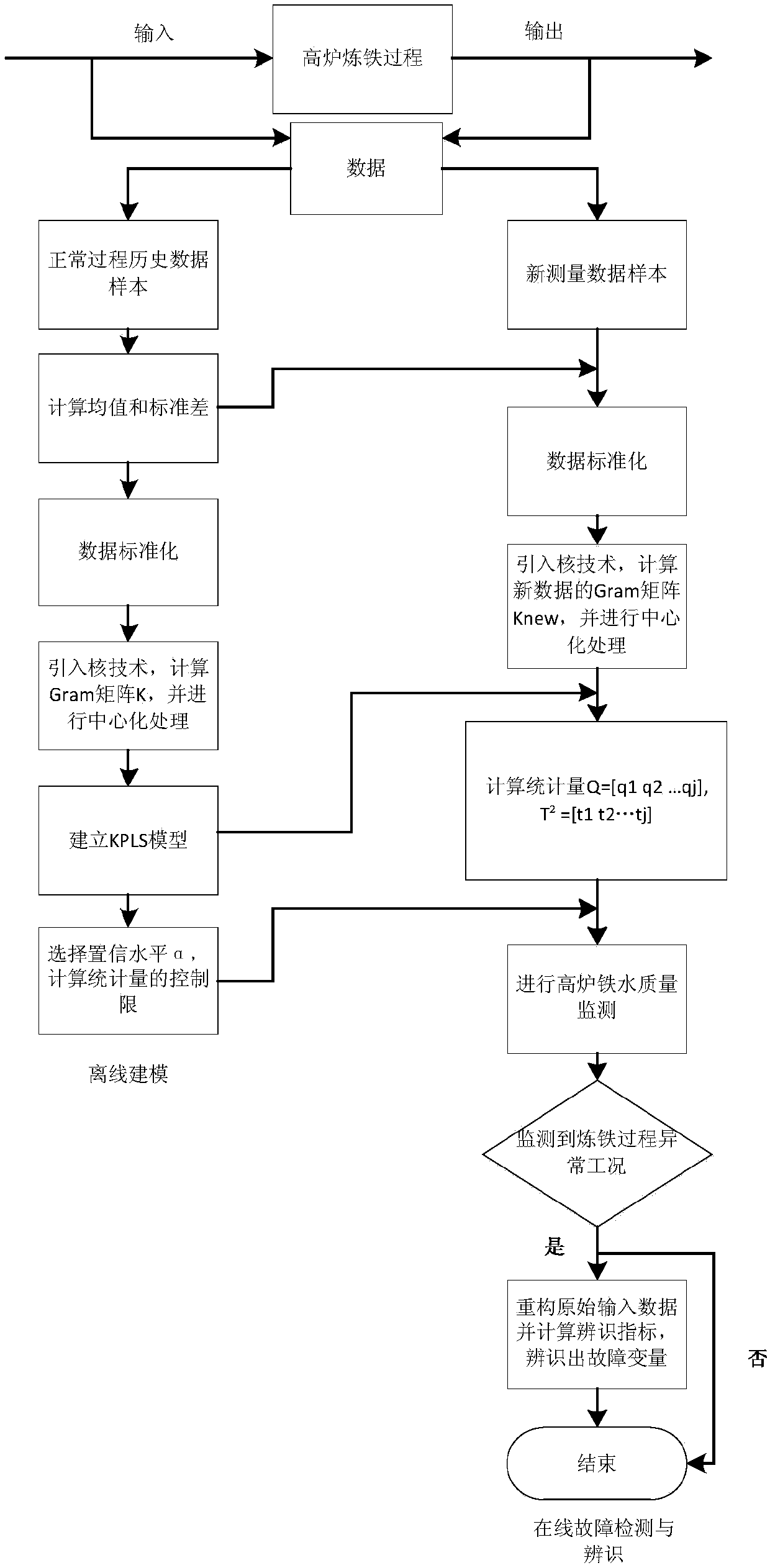

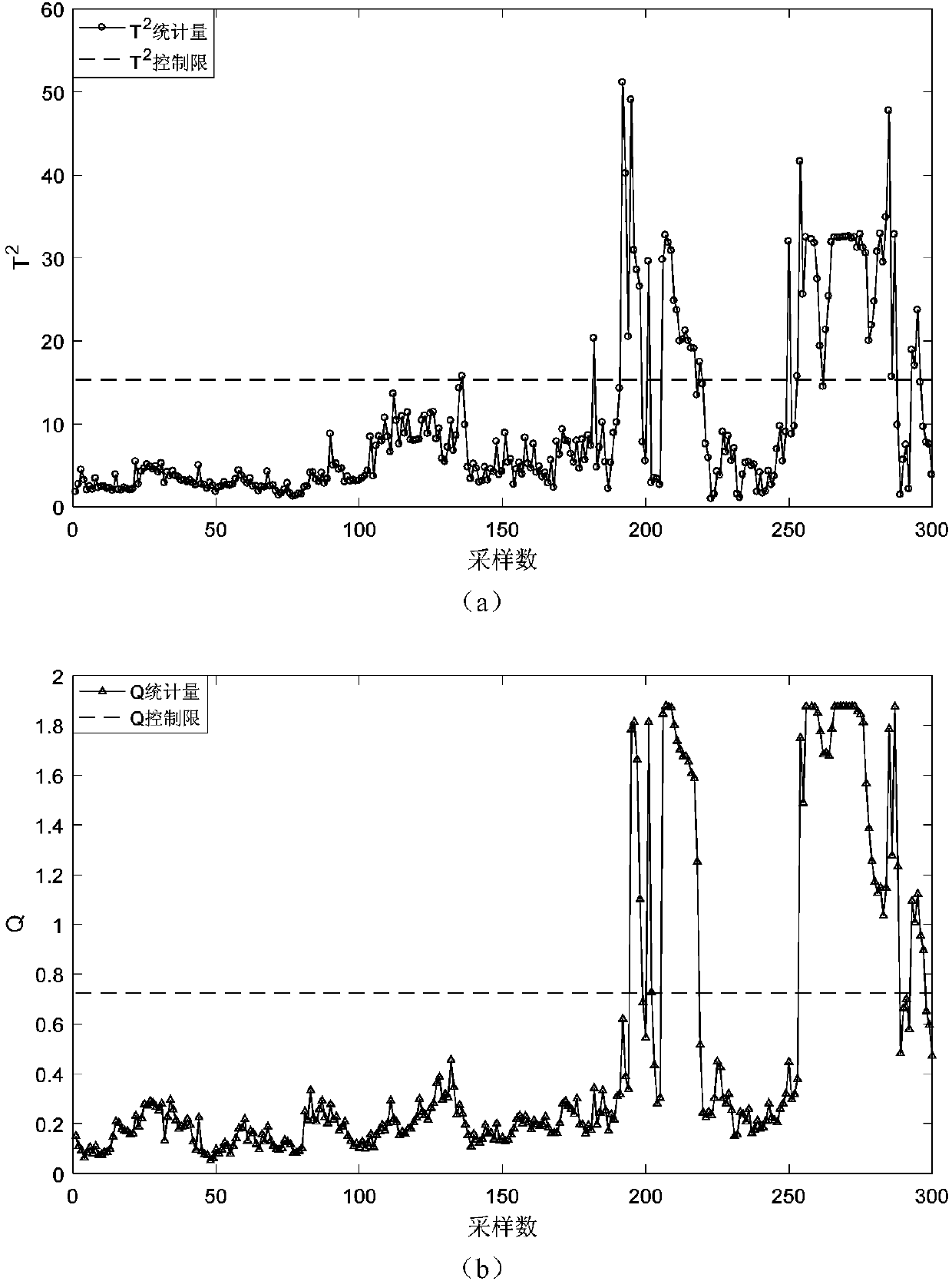

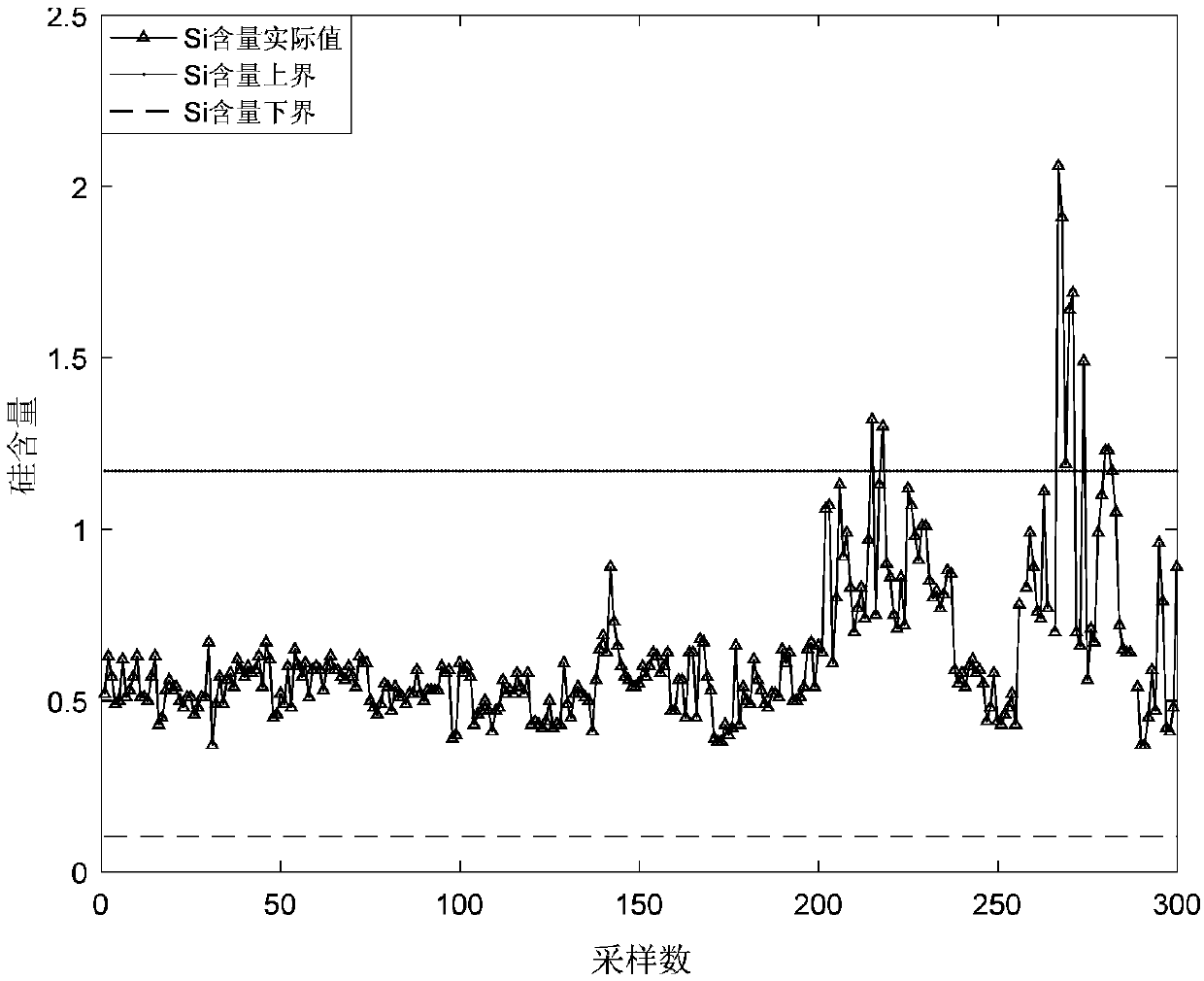

[0053] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0054] This embodiment provides a method for monitoring the quality of blast furnace molten iron based on KPLS (kernel projection to latent structures, kernel partial least squares) robust reconstruction error, including:

[0055] Step 1. Collect the blast furnace operating parameters and molten iron quality variables at the same time in the blast furnace ironmaking historical data, and use the blast furnace operating parameters as the input data matrix X, and the molten iron quality variables as the output data matrix Y:

[0056] The operating parameters of the blast furnace include variables measured by conventional detection instruments, variables adjusted at the upper and lower parts and variables obtained through calculation, including coke batch, ore batch, coke load, sintering ratio, cold air flow rate, air supply ratio, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com