Device for the abrasive machining of surfaces of elements and in particular optical elements or workpieces

a technology for abrasive machining and optical elements, applied in the direction of grinding/polishing apparatus, grinding machine, abrasive apparatus, etc., can solve the problems of large outlay, large polishing error, and always arisen problems with conventional methods and devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] The invention is based on the object of providing a device for abrasive machining of surfaces, and particularly for grinding and / or polishing of surfaces of optical components, which permits fast machining of the surface irrespective of the shape of the particular surface being machined.

[0006] An achievement of the object in accordance with the invention is set out in patent claim 1. Further developments of the invention are the subject matter of claims 2 to 10. Possible uses of the device of the invention are claimed in claims 11 to 14.

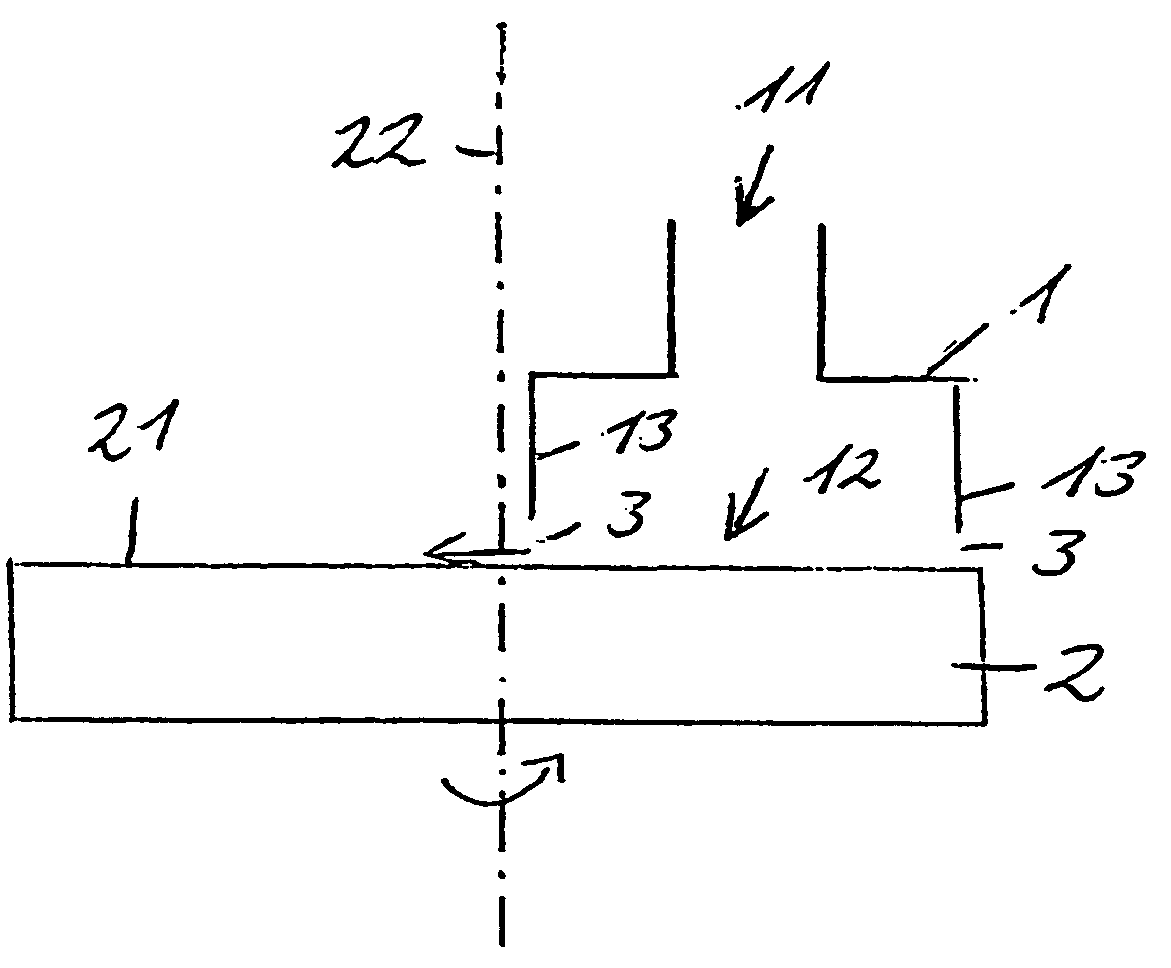

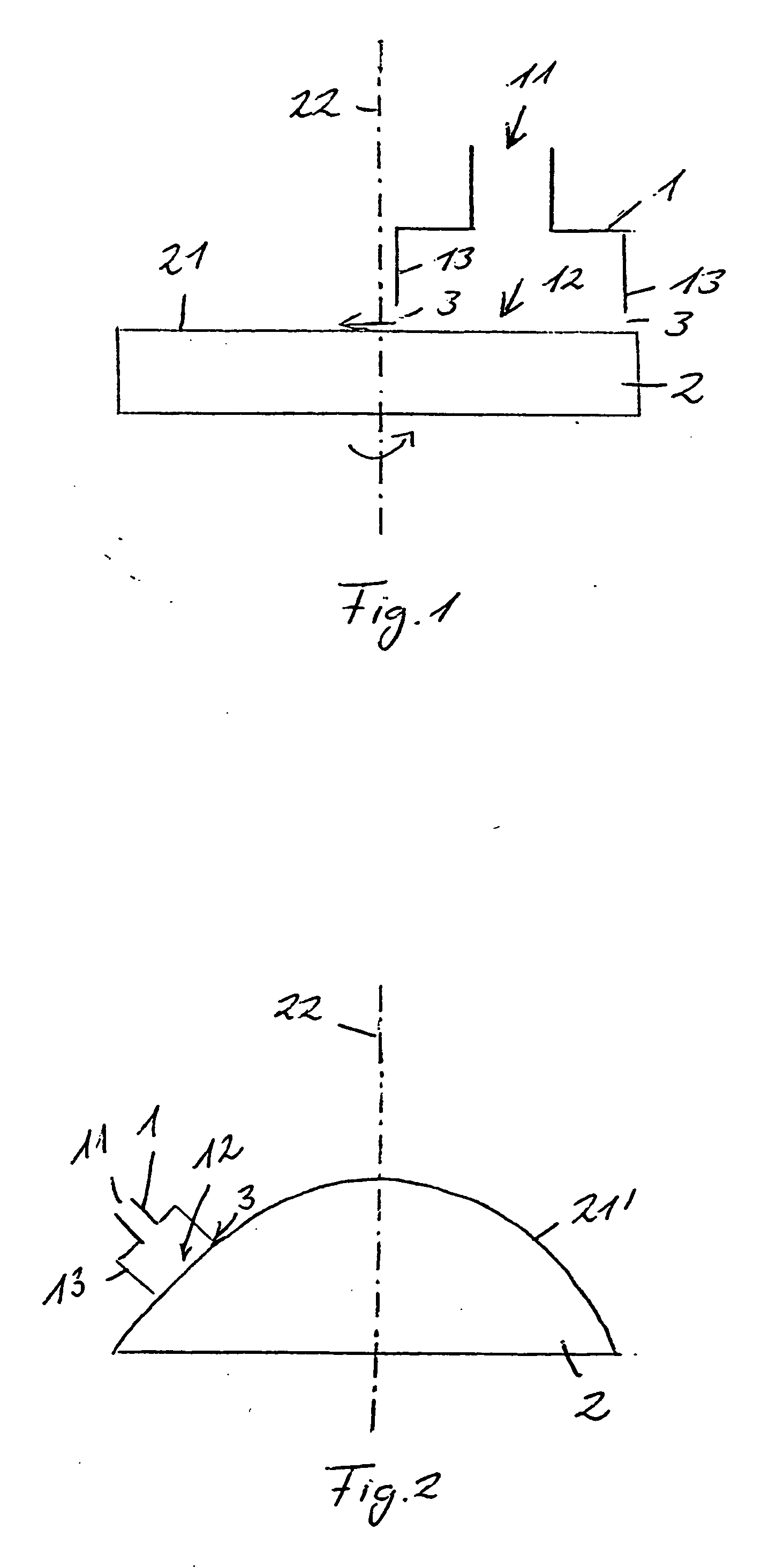

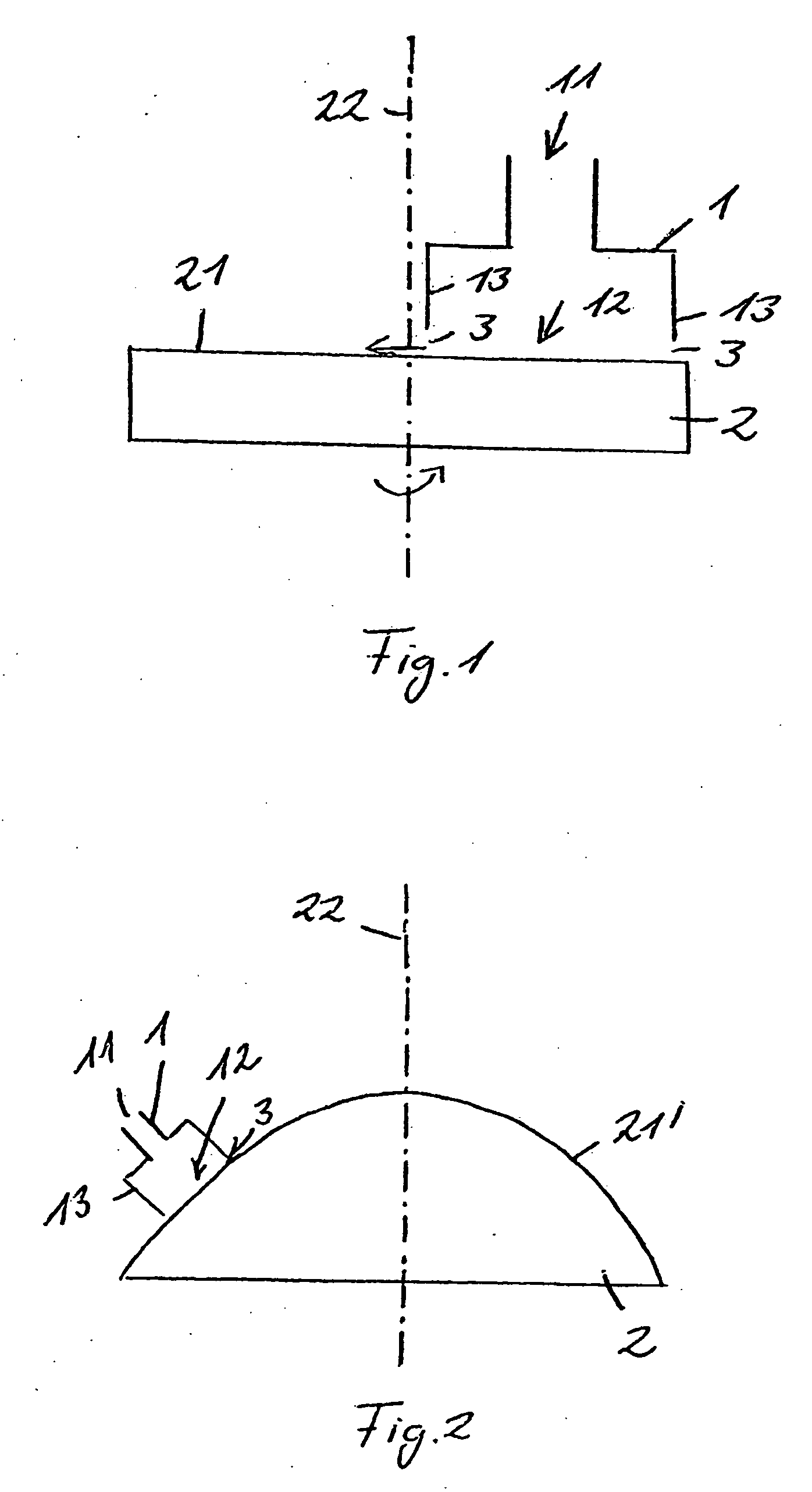

[0007] In accordance with the invention, the device for abrasive machining of surfaces and particularly for grinding and / or polishing optical components comprises a tool having a fluid inlet and a fluid outlet. A supply unit conveys a liquid in which abrasive agents are dissolved to the fluid inlet. This liquid flows through the tool to an outlet from which it emerges from the tool. According to the invention, this tool is positioned by a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com