Method for detecting depth of subsurface crack of optical material

A technology of optical materials and detection methods, applied in the direction of optical testing flaws/defects, preparation of test samples, etc., to achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

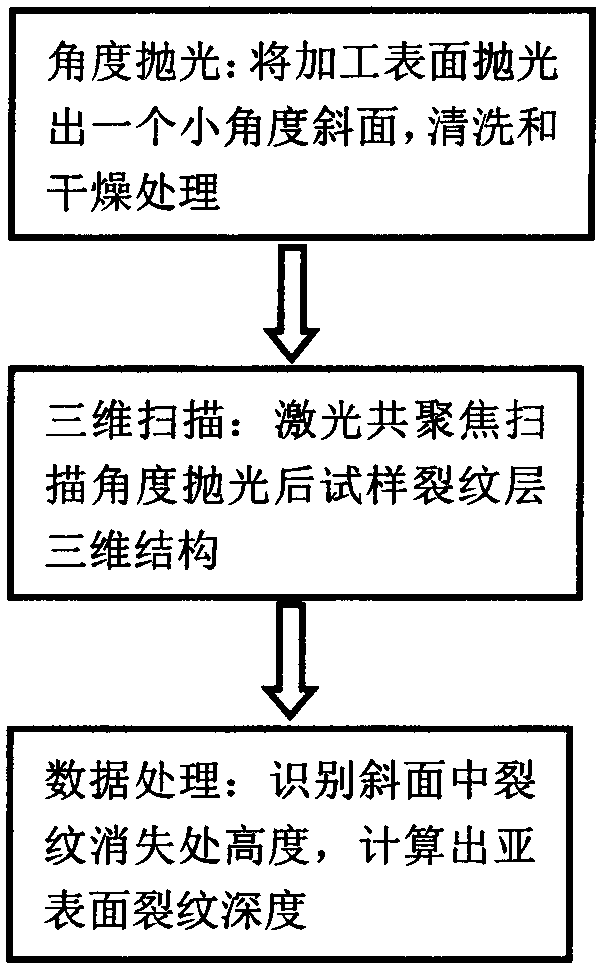

[0023] The subsurface crack depth detection method of K9 glass after abrasive grain processing, the detection process of this method is as follows figure 1 shown, including the following steps:

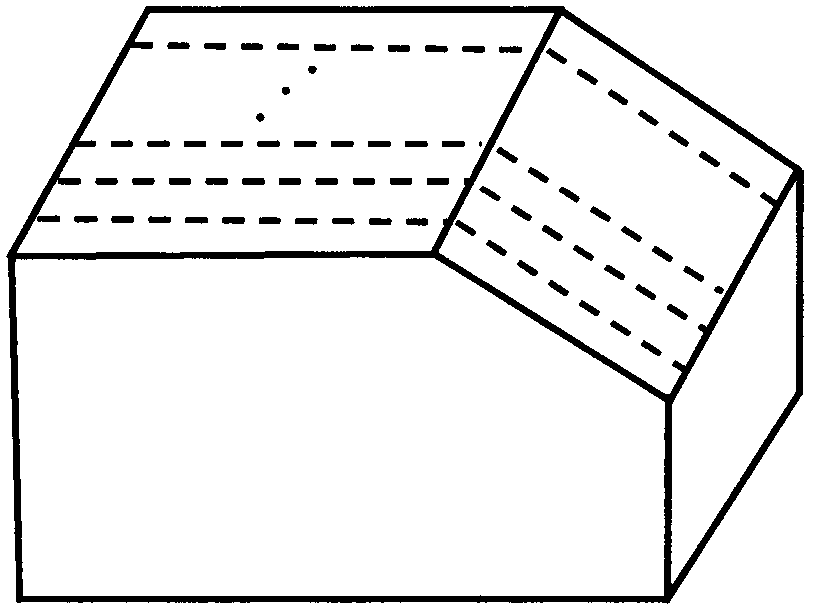

[0024] (1) Angle polishing: Bond the K9 glass sample to be tested on the angle polishing fixture, put it into a biaxial polishing machine, and use diamond micropowder with a particle size of W1 and cerium oxide polishing solution with a particle size of 0.5 μm for grinding. and polishing, the design angle of the angle polishing fixture is 6°; after grinding and polishing, the sample is etched in 1% HF solution for 5 minutes, taken out for ultrasonic cleaning, and then put into a vacuum drying oven for drying;

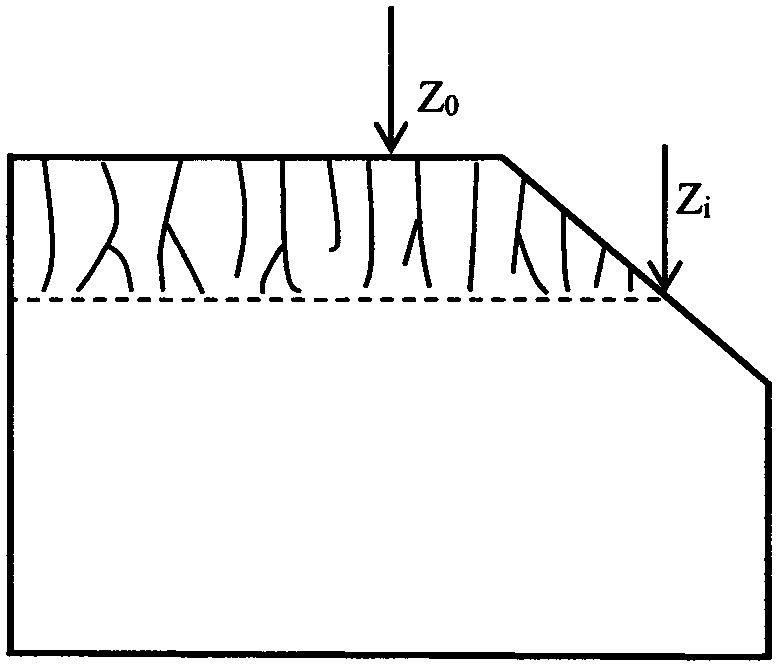

[0025] (2) Three-dimensional scanning: Olympus OLS4500 laser confocal microscope (Z-direction resolution 10nm) was used to perform three-dimensional tomographic scanning on the sample after angle polishing to obtain the three-dimensional structure of the crack layer;

[0026] ...

Embodiment 2

[0029] The subsurface crack depth detection method of the Si wafer after abrasive grain processing, the detection process of this method is as follows figure 1 shown, including the following steps:

[0030] (1) Angle polishing: the Si wafer sample to be measured is bonded on an angle polishing fixture, put into a biaxial lapping machine for grinding and chemical mechanical polishing, and the design angle of the angle polishing fixture is 6°; grinding and polishing Finally, put the sample into the "Young's" solution to etch for 30s, take it out for ultrasonic cleaning, and then put it in a vacuum drying oven to dry;

[0031] (2) Three-dimensional scanning: Olympus OLS4500 laser confocal microscope (Z-direction resolution 10nm) was used to perform three-dimensional tomographic scanning on the sample after angle polishing to obtain the three-dimensional structure of the crack layer;

[0032] (3) Data processing: Since the measured object is a non-transparent material, the three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com