Expendable unitary quick mount abrasive discs and support pad therefor

a technology of abrasive discs and support pads, which is applied in the direction of gear teeth, manufacturing tools, gear teeth, etc., can solve the problems of excessive downtime necessitated by such disc replacement, difficulty in removing the nuts in order to replace the disc, and damage to the workpi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

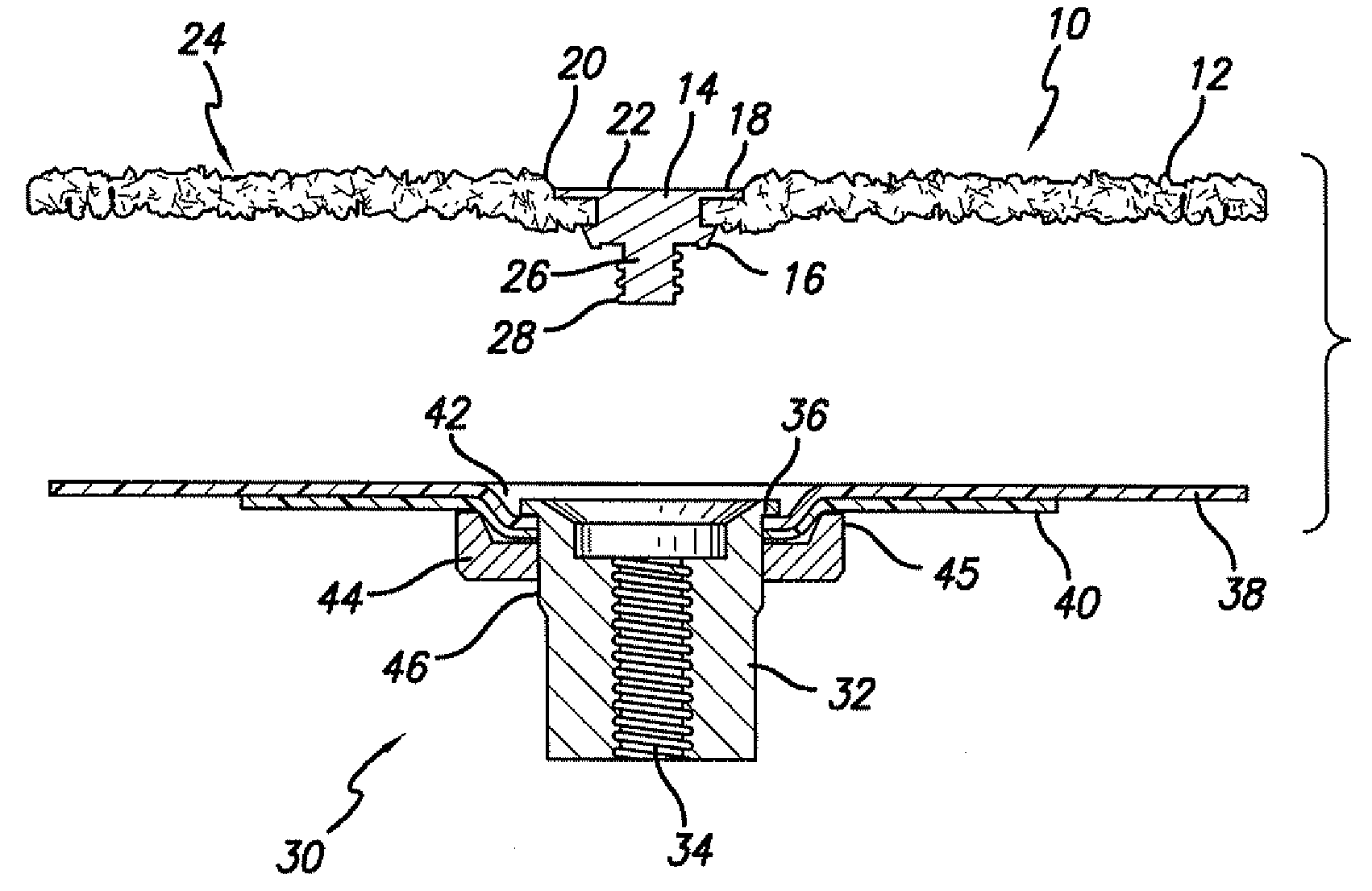

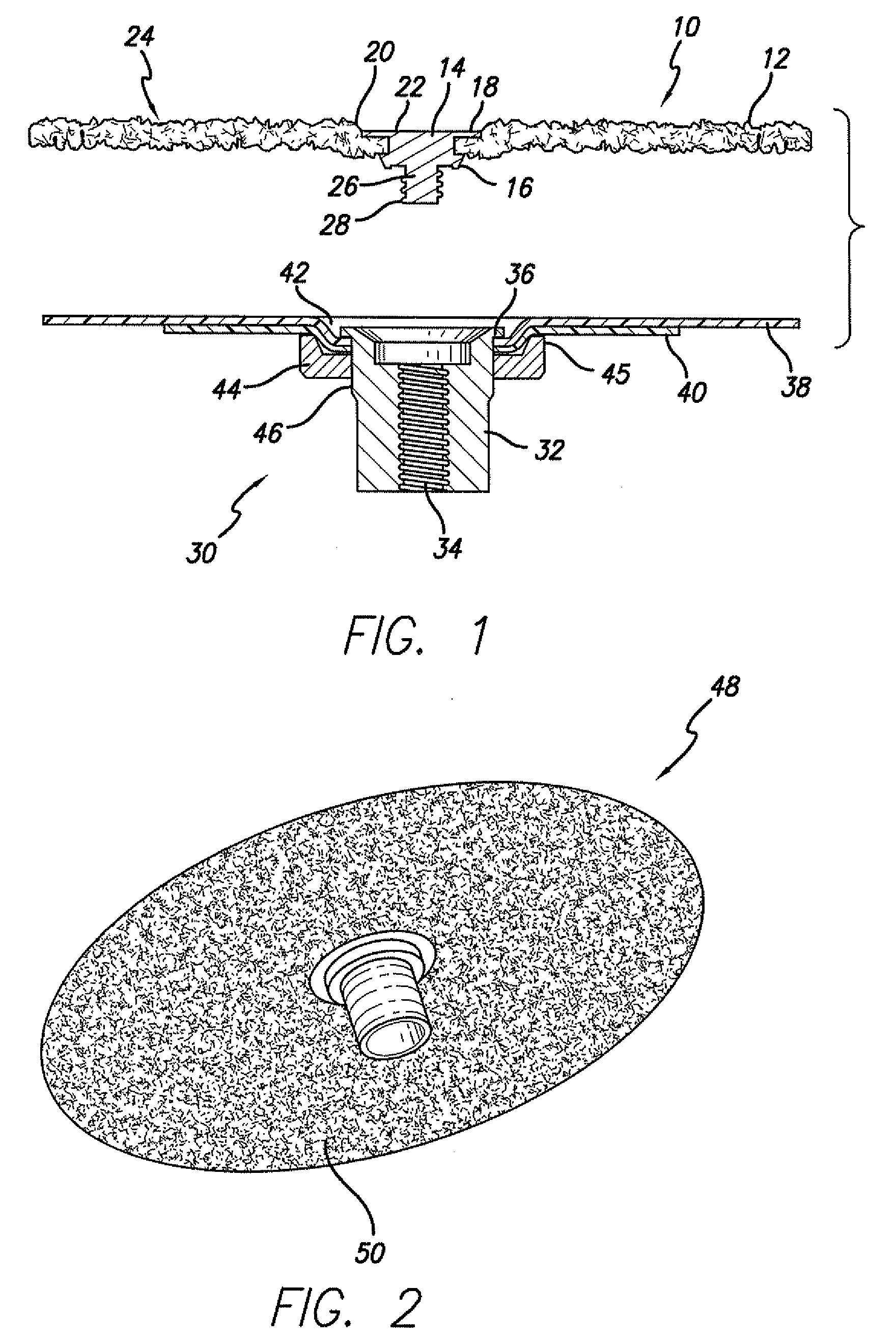

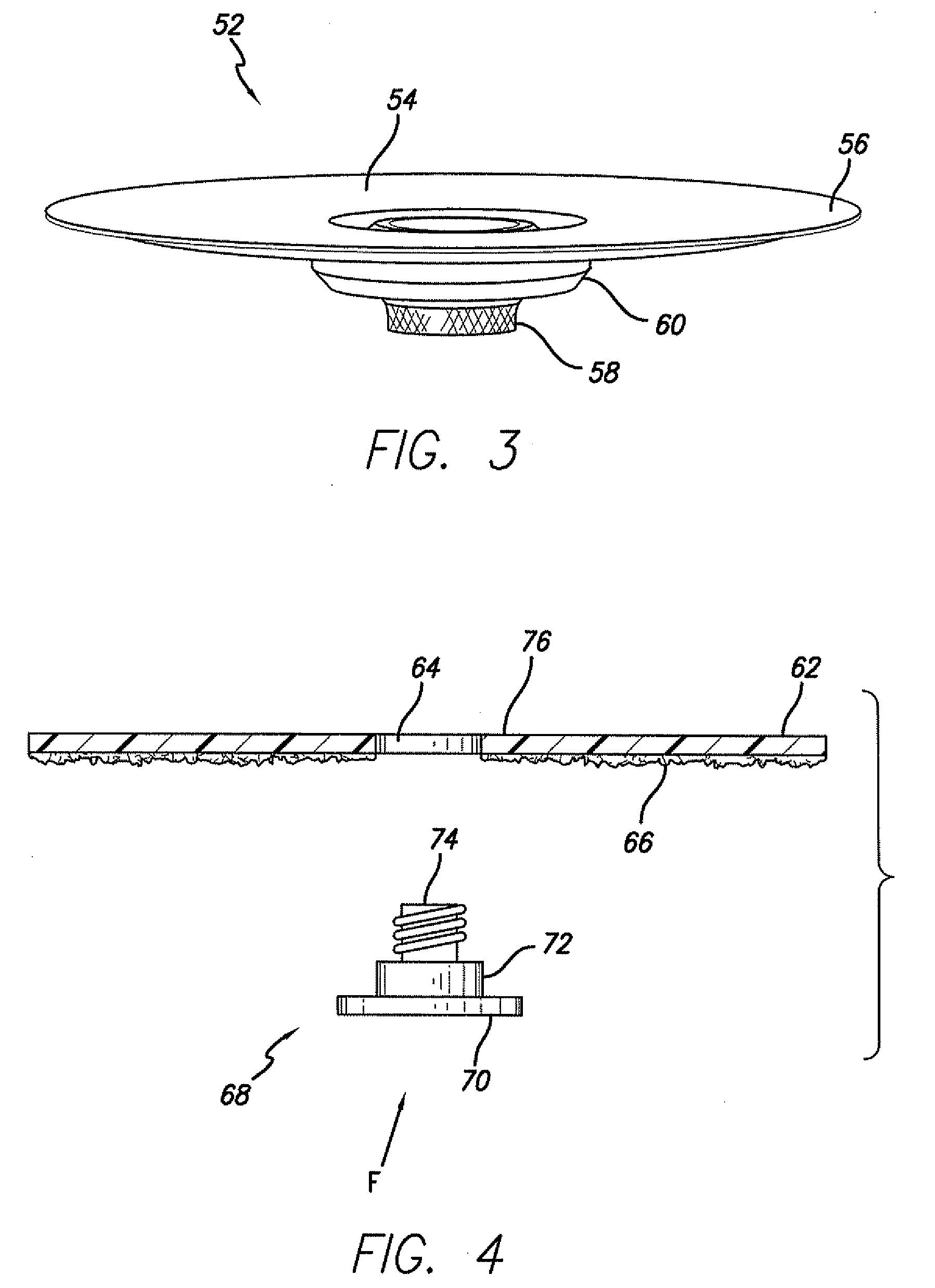

[0024]The present invention provides an abrasive finishing disc having a fastener affixed thereto in such a manner that the abrasive finishing disc forms a depressed center such that the flange which holds the abrasive disc to a support pad is disposed completely below the surface of the abrasive finishing material which forms a part of the abrasive disc thereby maximizing the amount of surface area which is usable. The abrasive discs may be made of coated cloth or fiber or non-woven three dimensional fibrous abrasive material as is taught in U.S. Pat. No. 5,858,140 or such material having a reinforcing scrim as taught in U.S. Pat. No. 3,688,453. The fastener device includes a threaded shaft having male or female threads for attachment to a support pad. The support pad includes a depressed center area which cooperates to receive the depressed portion on the abrasive disc so that when the disc is fastened in place for use on the support pad, the fastener flange remains disposed below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com