Three-dimensional cooperative distribution method for various grinding materials for preparing superhard tool

A technology of superhard tools and abrasives, applied in the direction of manufacturing tools, grinding devices, metal processing equipment, etc., can solve the problem that abrasive tools are difficult to exert long-term and stable characteristics, sintering tools or brazing and electroplating tools are difficult to carry out, The load of the saw blade is too large to continue to use, etc., to achieve the effect of good suitability, good processing adaptability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (4) The preparation in step (3) is brazed and heated, and the preparation can be a three-dimensional structure formed by the cooperative arrangement of multiple abrasives on the surface of a superhard tool; it can also be a variety of abrasives and The three-dimensional space structure formed after the brazing alloy powder is mixed.

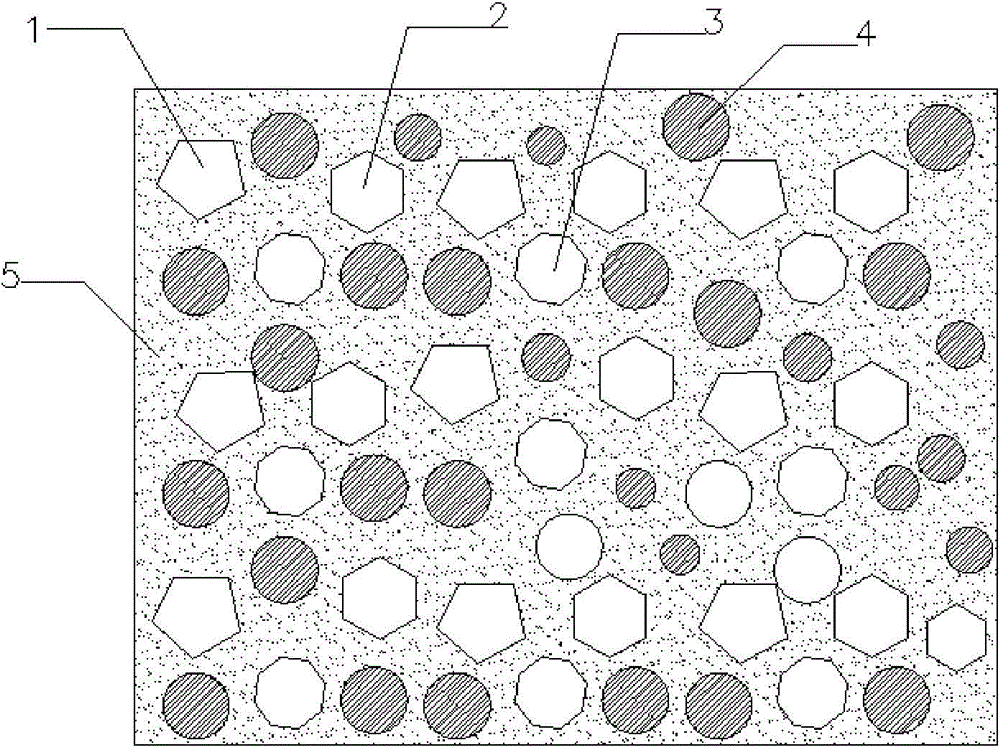

[0043] The main abrasives responsible for the main processing in step (1) include natural diamond, artificial diamond, CBN (cubic boron nitride), polycrystalline diamond, polycrystalline CBN and other superabrasive types applied to material processing, which are characterized by processing The abrasive grains have high strength and slow wear. The abrasive grains are mainly used to form cutting action to remove materials. The grain size ranges from 1 mesh to 300 mesh.

[0044] Auxiliary abrasives are mainly: silicon carbide (green silicon carbide, black silicon carbide, etc.), alumina (brown corundum, white corundum, single crystal corundum...

example 1

[0060] (1) Prepare a saw blade head for long-term cutting of the edge of high-speed rail track slabs. Saw blade dimensions: (Maximum outer diameter)× (installation aperture) × 4mm (thickness), saw blade head size: (Inner diameter of cutter head)×40mm (length of cutter head)×12mm (height of cutter head)×4mm (thickness of cutter head) requires that the prepared cutter head can perform stable, efficient and long-life cutting process on concrete and rebar.

[0061] The three-dimensional collaborative arrangement method of various abrasives is as follows:

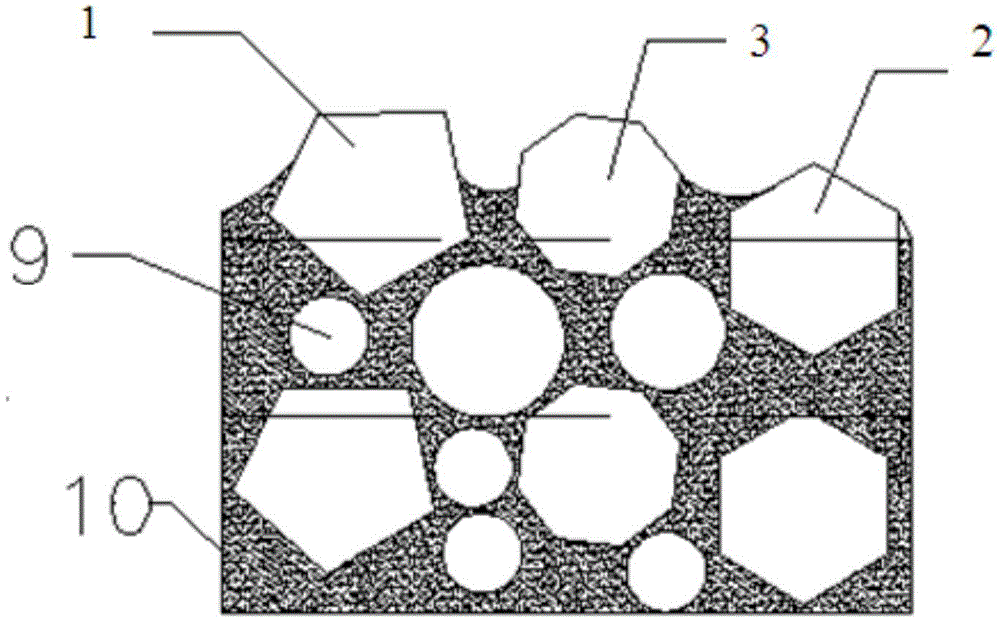

[0062] 1. Since the material to be cut is reinforced concrete and the material is a composite type, two main abrasives are required, diamond and cubic boron nitride are used to cut concrete and steel respectively, and because the chip removal space is small during cutting, it prevents cutting In case of stuck phenomenon, green silicon carbide abrasive is used as auxiliary abrasive, and green silicon carbide abrasive can re...

example 2

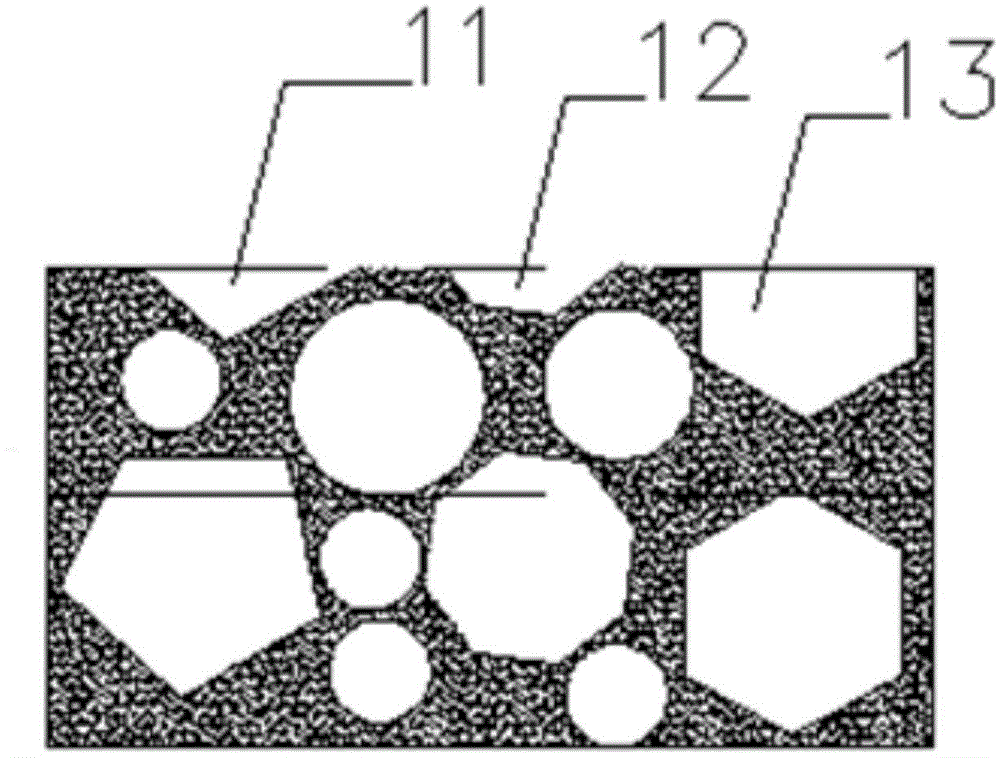

[0070] A grinding wheel for grinding and polishing hard and brittle stone is prepared. Grinding disc type: (Outer diameter) × 40mm (total height), 9 flat grinding blocks are welded on the plane, and the prepared grinding blocks are required to be able to perform stable, efficient, and long-life grinding and polishing on granite, marble, and ceramics.

[0071] The three-dimensional collaborative arrangement method of various abrasives is as follows:

[0072] 1. Determine the abrasive particle parameters according to the processing requirements. The requirements are mostly used for processing hard and brittle materials, and the scope of application is wide. It is suitable for processing them with major abrasives such as diamond and polycrystalline diamond. Due to the need for a certain polishing effect, stability and accuracy It must be considered that the auxiliary addition of alumina abrasives can have a better chip removal effect, and the formed cavity has a certain lubrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com