Mandrel power mechanism for cold rolling machine

A technology of power device and rotating device, which is applied to the driving device of metal rolling mill, metal processing equipment, metal rolling, etc., which can solve the problem of poor working environment on the contact surface of the core roll, reduced service life of finished bearings, and reduced service life of the core roll and other problems, to achieve the effect of increasing the surface finish of precision machining, improving fatigue resistance and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

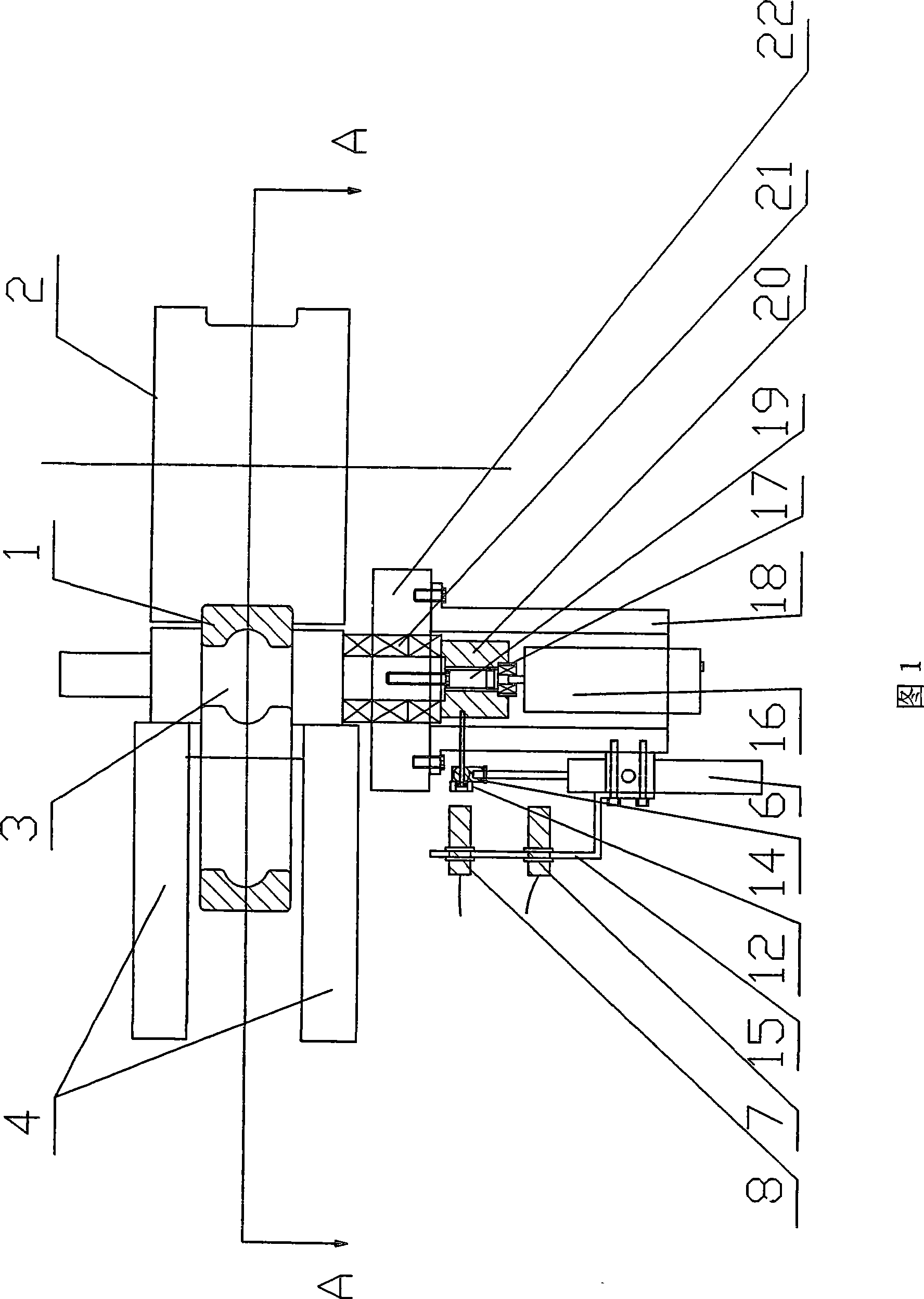

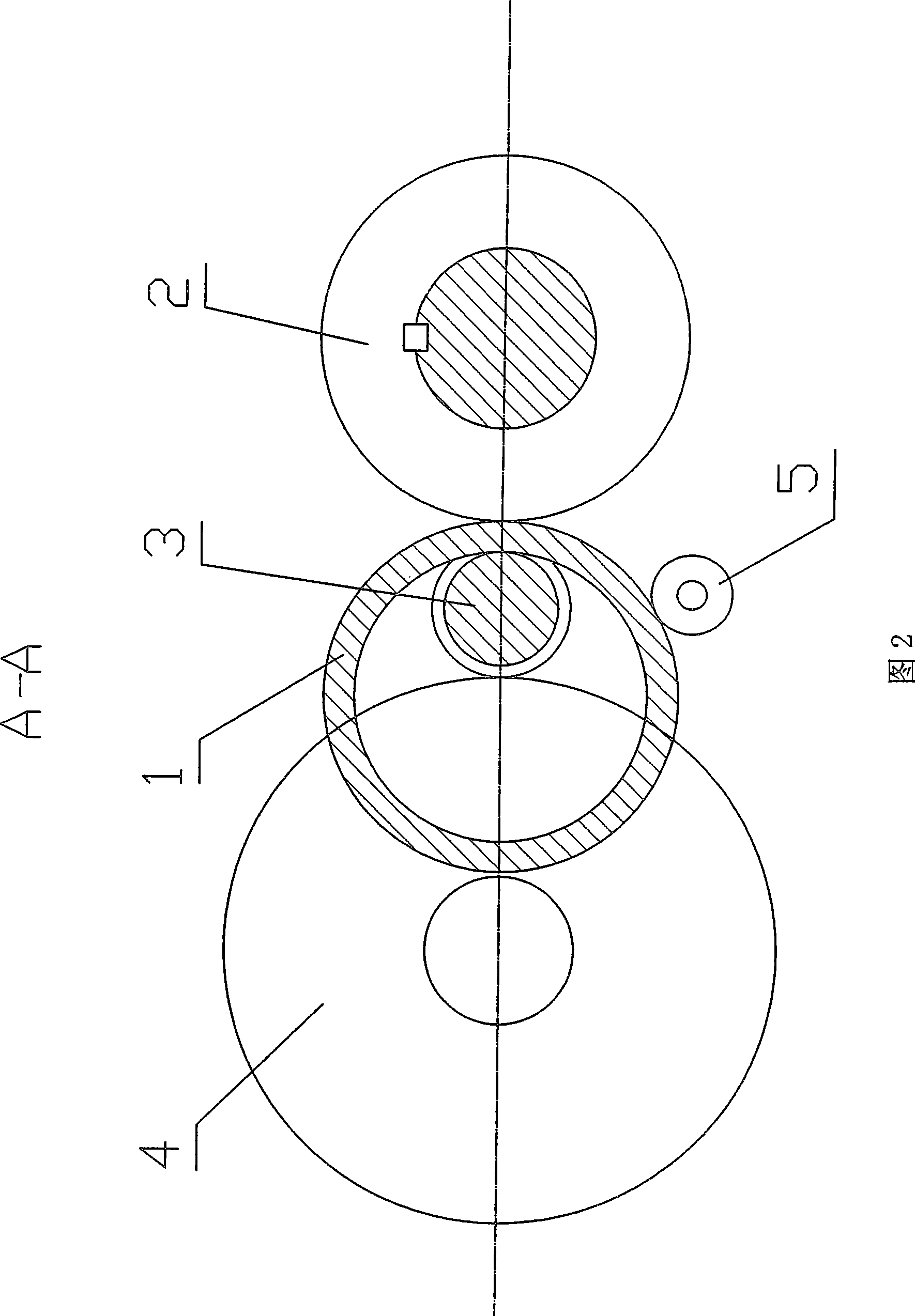

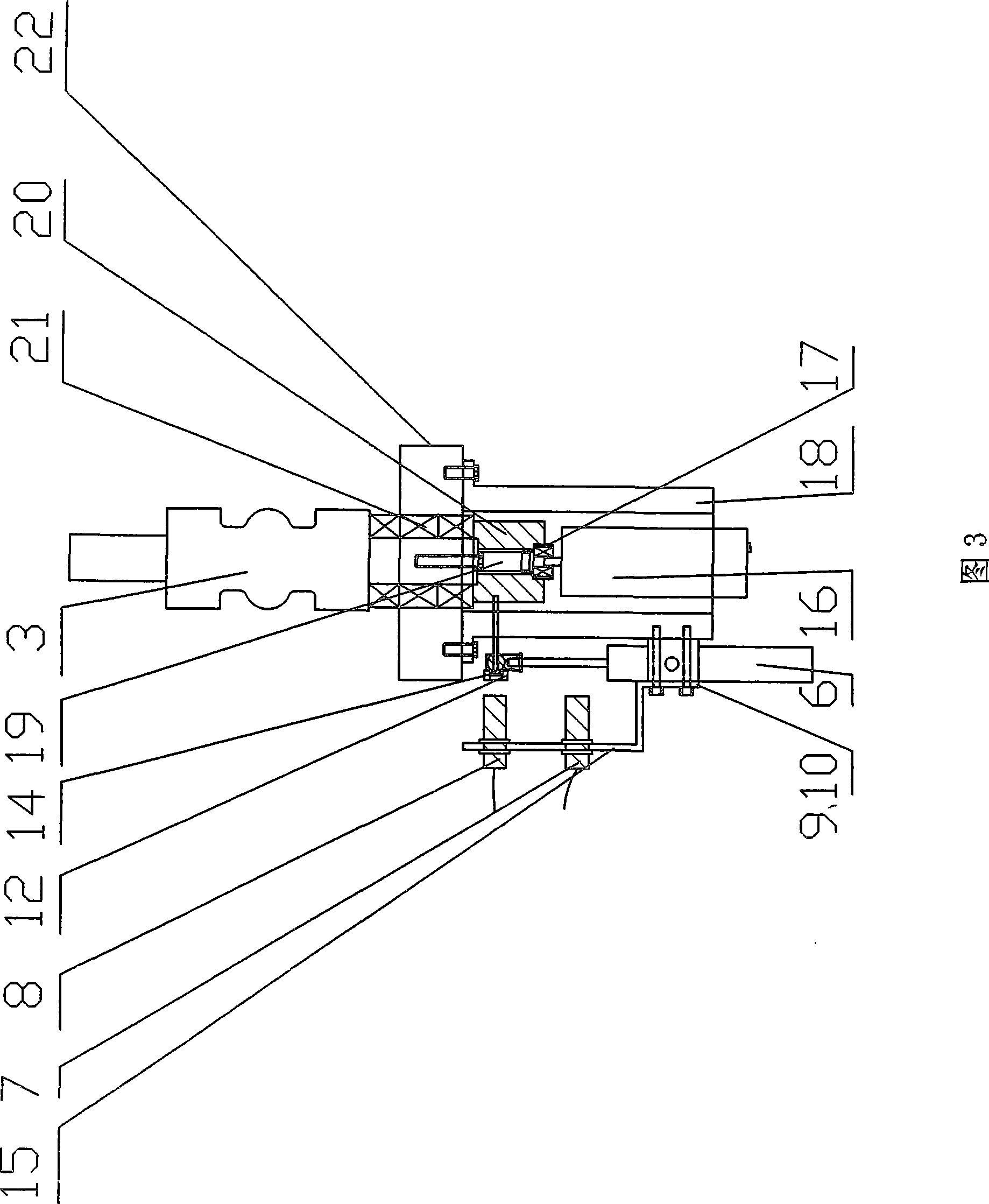

[0020] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0021] In the figure: 1-processing workpiece, 2-rolling wheel, 3-core roller, 4-support wheel, 5-roundness roller, 6-hydraulic cylinder, 7-rear limit switch, 8-front limit switch, 9-oil cylinder fixation Clamping block, 10- cylinder positioning bracket, 12- cylinder rod fixing screw, 14- cylinder rod joint head, 15- fixed bracket plate, 16- DC brushless motor, 17- coupling with built-in overrunning clutch, 18- support Seat, 19-core roller fixed end shaft, 20-core roller bushing connecting body, 21-core roller sleeve and bearing, 22-core roller seat.

[0022] As shown in Figure 1 and Figure 3, the active device of the cold rolling core roll includes a horizontal moving device, a rotating device, a detection device, and a connecting body. The core roller 3 has a core roller sleeve and a bearing 21 outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com