Machine learning-based robot grinding method

A machine learning and robot technology, applied in the field of grinding, can solve the problems that manual operation cannot guarantee the consistency of grinding precision, low processing efficiency, and poor system versatility, so as to improve grinding precision and production efficiency and avoid blindness Sexuality, the effect of high quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The robot grinding method based on machine learning proposed by the present invention is described in detail as follows in conjunction with accompanying drawings and embodiments:

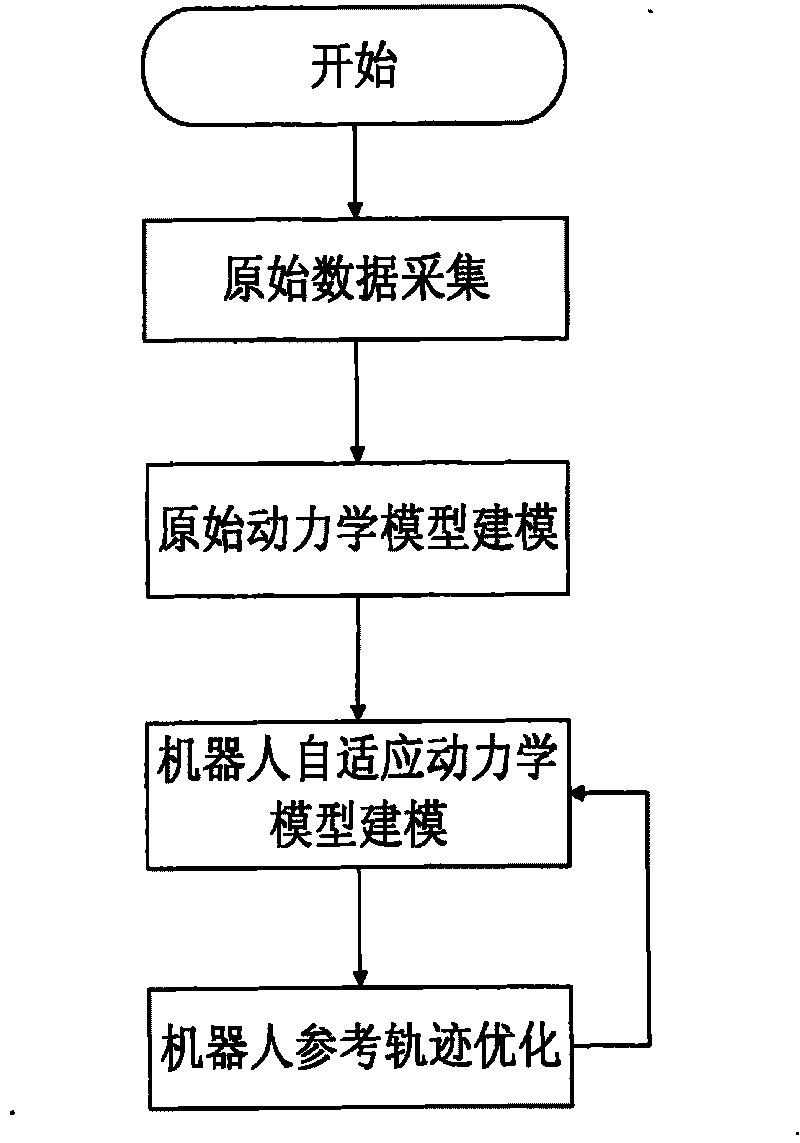

[0030] The overall process of the inventive method is as figure 1 As shown, the details are as follows:

[0031] 1) Raw data collection: In each stage of abrasive belt work, a large number of workpieces of different materials (in this embodiment, aviation aluminum alloy, brass, magnesium alloy, titanium alloy, ductile iron and hard alloy) are ground In the experiment, measure the contact force f between the workpiece and the grinding wheel with a six-dimensional force sensor, measure the curvature s and the grinding amount u of the grinding surface of the workpiece with a three-dimensional measuring instrument, measure the processing speed v with a position sensor, and then store it in the form of a vector:i f i v i the s i >, i=1, 2...N, N is the number of sets of raw data (at least 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com