Resistance type double-melting stacking three-dimensional metal member manufacturing forming system

A metal component and resistive technology, which is applied in the field of rapid three-dimensional forming of metal parts, can solve the problems of high harmless temperature, low manufacturing precision, and harmful to human body, and achieve the effects of improving product quality, simplifying the system, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

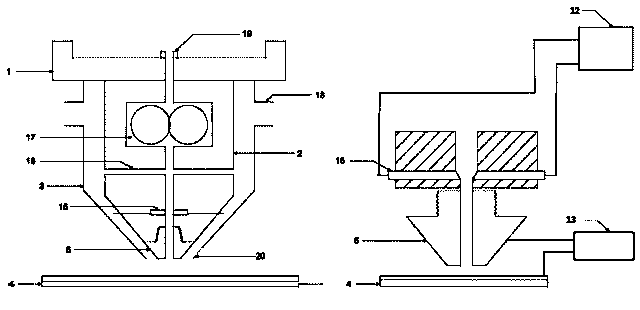

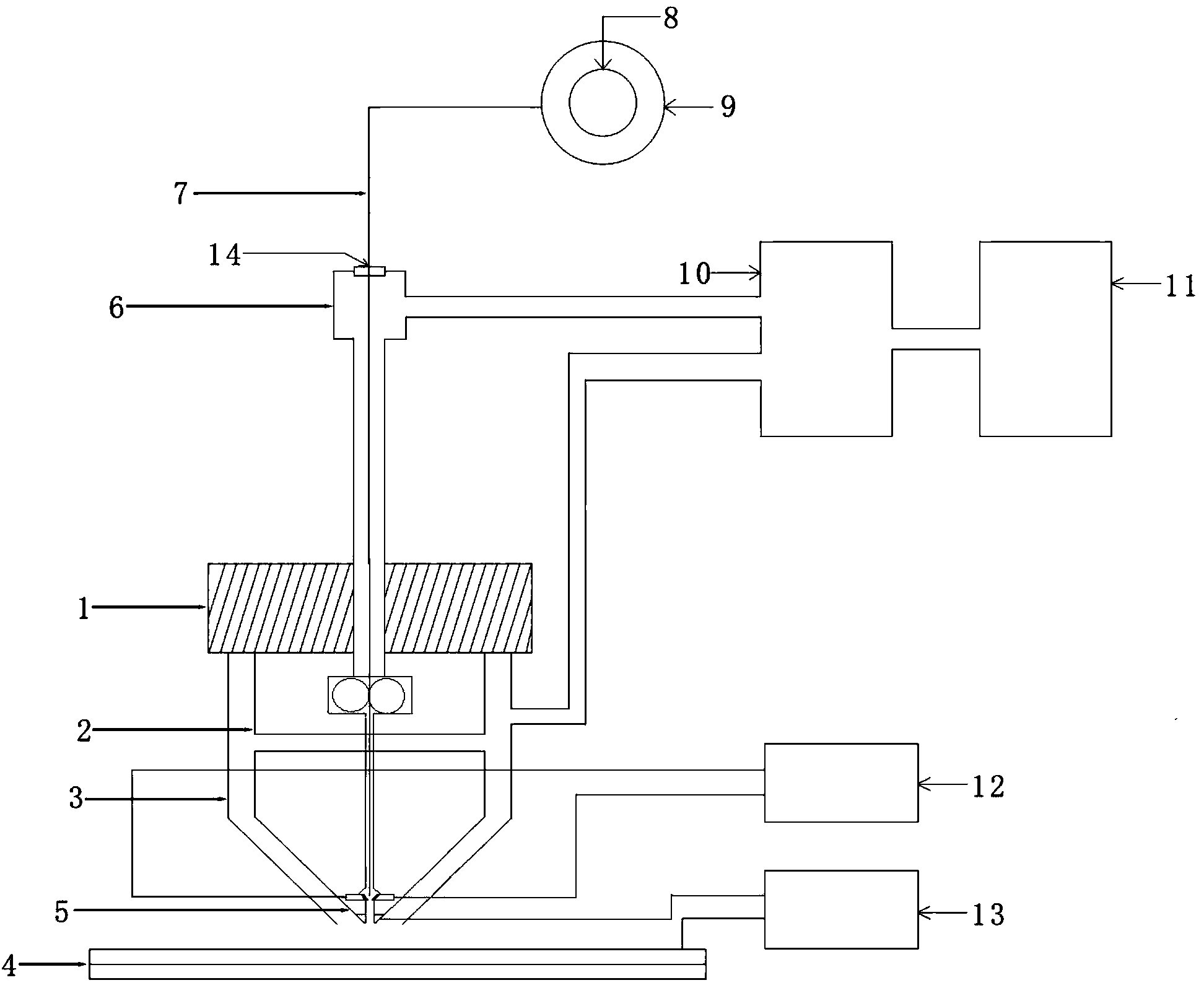

[0030] see figure 1 —2 The manufacturing and forming system of resistive double-melting laminated three-dimensional metal components consists of four parts: material release system, melting and forming system, cooling and anti-oxidant delivery system, and high-power power supply. The material release system includes a fuse reel 9 and a fuse reel motor 8. When the forming head 2 is moved to a designated position, the fuse reel motor 8 starts to release the fuse 7 from the fuse reel 9. The cooling and anti-oxidation system consists of an anti-oxidation protection tube 6, an air pump 10, and a liquid inert gas storage evaporation tank 11. After the fuse is released, it enters the anti-oxidation protection tube 6 through the rubber sealing port 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com