Bamboo scrap and waste plastic PE composite outdoor building material and application thereof

A technology of waste plastics and old plastics, which is applied in the field of building material production and manufacturing, can solve the problems of high cost, achieve cost reduction, ensure performance, and realize the effects of waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with specific embodiment:

[0021] The composite outdoor building material of the present invention is compounded by bamboo chips, old plastic PE with lower cost and auxiliary agents, wherein the content (percentage by weight) of bamboo chips is 65%, the content of old plastic PE is 30%, and the content of auxiliary agents is 5%, additive components and their percentages are: stearic acid 0.7, terpene resin 0.5, silane coupling agent 0.1, phthalate coupling agent 0.1, polyethylene wax 0.3, paraffin wax 0.4 iron red 0.9, titanium dioxide 1.4 , triphenyl phosphite 0.3, antioxidant (1010) 0.3.

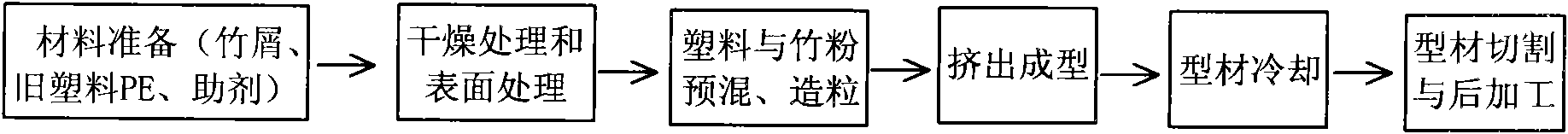

[0022] The building material production process of the present invention comprises: according to above-mentioned proportioning, make the bamboo chip particle be 120 orders, PE selects commercially available standard particle size, with bamboo chip drying and surface treatment, kneading in kneading pot obtains premix;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com