Full-automatic plastic-package packaging robot based on PLC

A robotic and fully automatic technology, applied in packaging, transport packaging, multiple packages, etc., can solve the problems of large research and development and application space of fruit and vegetable packaging machinery, and achieve the effect of simplified structure, easy operation and easier realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

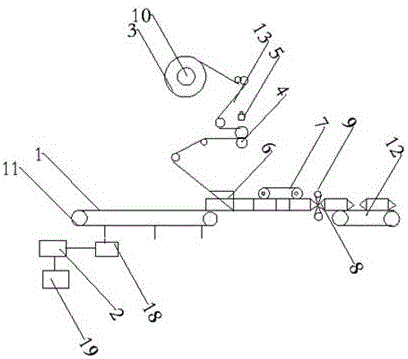

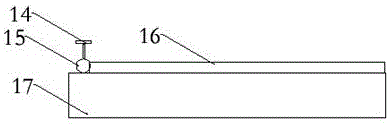

[0014] Example: see figure 1 and figure 2 , the present invention provides a technical solution: a fully automatic plastic packaging robot based on PLC, including a material transfer module 1, a film feeding shaft 10, and a control module 2, and the material transfer module 1 is composed of a push rod 14, a conveying chain 15, The guide rail 16 and the conveying platform 17 are composed of, and it is characterized in that: the push rod 14 is located on the conveying chain 15, and is connected with the conveying chain 15 in a hinged manner, and the conveying chain 15 is wound on the feeding shaft 11; Wrapped with a packaging film 3, the packaging film 3 is connected to the film driving roller 4 through the traction conveyor 13, the packaging film 3 is connected to the bag forming device 6 through the film driving roller 4, and the object wrapped by the bag forming device 6 After being pressed by the brush 7, it is sent to the end sealing and cutting mechanism 8. The scissors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com