White tea processing method

A processing method and white tea technology, applied in tea, tea extraction, food science, etc., can solve the problems of too long time, insufficient oxidation, and high consumption of biochemical components, etc., to increase soluble sugar, improve permeability, and maintain activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

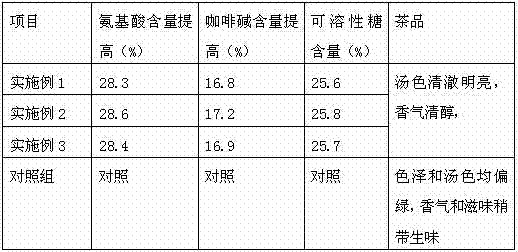

Examples

Embodiment 1

[0018] A processing method for white tea, comprising the following steps:

[0019] (1) Pick the standard tea leaves of 3-year-old tea trees with one bud and two leaves in the first ten days of March, cover them with plastic wrap immediately after picking, transport them back to the processing workshop, and spread the fresh tea leaves thinly in a water sieve with a diameter of 1.0 meters. 2 mm, the leaves do not overlap, put the water sieve on the green rack, put it in the withering room, keep the room ventilated, the temperature is in the range of 16-18 °C, and the relative air humidity is in the range of 75-78%, the first step of withering stages;

[0020] (2) Take out the prepared refrigerated cellulase solution before withering, put it in a watering can, and place it in the withering room for 3 hours. After withering for 80 minutes, spray the cellulase solution evenly on the withered leaves to form Thin water mist, at the same time, the temperature in the withering room is...

Embodiment 2

[0027] A processing method for white tea, comprising the following steps:

[0028] (1) Pick the standard tea leaves of 3-year-old tea trees with one bud and two leaves in the first ten days of March, cover them with plastic wrap immediately after picking, transport them back to the processing workshop, spread the fresh tea leaves in a water sieve with a diameter of 1.2 meters, and spread the tea leaves to a thickness of 2.5 mm, the leaves do not overlap, put the water sieve on the green rack, place it in the withering room, keep the room ventilated, the temperature is in the range of 16-18 ℃, and the relative humidity of the air is in the range of 75-78%, the first step of withering stages;

[0029] (2) Take out the prepared refrigerated cellulase solution before withering, put it in a watering can, and place it in the withering room for 3.5 hours. After withering for 85 minutes, spray the cellulase solution evenly on the withered leaves to form Thin water mist, at the same t...

Embodiment 3

[0036] A processing method for white tea, comprising the following steps:

[0037] (1) Pick the standard tea leaves of 4-year-old tea trees with one bud and two leaves in the first ten days of March, cover them with plastic wrap immediately after picking, transport them back to the processing workshop, and spread the fresh tea leaves in a water sieve with a diameter of 1.3 meters, and the thickness of the spread is 3 mm, the leaves do not overlap, place the water sieve on the green rack, place it in the withering room, keep the room ventilated, the temperature is in the range of 16-18 °C, and the relative humidity of the air is in the range of 75-78%, the first step of withering stages;

[0038](2) Take out the prepared refrigerated cellulase solution before withering, put it in a watering can, and place it in the withering room for 4 hours. After withering for 90 minutes, spray the cellulase solution evenly on the withered leaves to form Thin water mist, at the same time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com