Manufacturing method of wicker plaiting vase

A production method and vase technology, which can be applied to vases and other directions, can solve the problems of unscientific processing methods of wicker, wicker vases cannot hold water, and cannot emit flower fragrance, etc., and achieve easy peeling and weaving processes, scientific and reasonable production methods, and softening effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for making a willow vase, comprising the following steps:

[0027] (1) Harvest wicker with uniform thickness, lay it flat and dry until the leaves are dry, and when the water content of the leaves is lower than 3%, remove the dry leaves;

[0028] (2) Wash the wicker after removing leaves with clear water to remove impurities, then put it into the pretreatment solution at 70 degrees Celsius and soak for 1 hour, peel off the willow bark after taking it out, and rinse it with clear water;

[0029] (3) laying the wicker treated in step (2) in the air until the moisture content of the wicker is lower than 25%, then soaking it in a special floral fragrance liquid for 4 hours, and then washing it with clear water;

[0030] (4) Take out the washed wicker, dry it with hot air at 50 degrees Celsius until the water content is between 20% and 30%, then soak it in a special floral fragrance liquid for 2 hours, and then wash it with water;

[0031] (5) Dry the moisture on t...

Embodiment 2

[0037] The preparation method of the above-mentioned special floral fragrance liquid is as follows: take an equal amount of roses, jasmine, peony, freesia, lily of the valley, daffodils, tulips, add 70% alcohol by total weight, fully smash and mix with a pulverizer, and then After filtering with filter paper, the special floral fragrance liquid is obtained.

Embodiment 3

[0039] The preparation method of the above-mentioned special floral liquid is as follows: take the same amount of roses, osmanthus, peony, clove, freesia, lily of the valley, daffodils, tulips, add 70% of the total weight of alcohol, and fully crush them with a grinder Mix, and then filter with filter paper to obtain a special floral liquid.

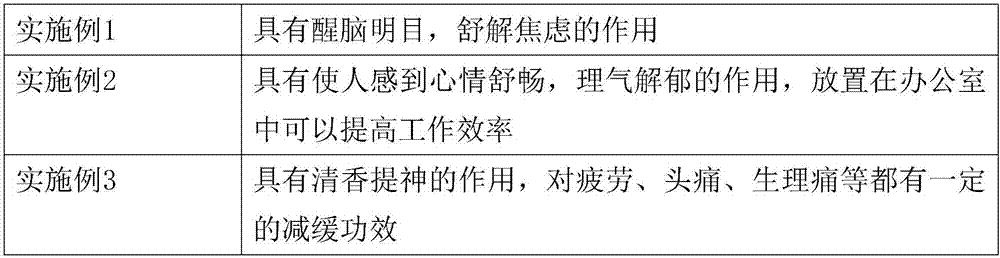

[0040] Each embodiment makes the effect of vase:

[0041]

[0042] The manufacturing method of the wicker vase provided by the invention is scientific and reasonable, the peeling and weaving processes are easier, the finished product is of good quality, does not break, and can emit flower fragrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com