Processing method for increasing low-grade tobacco use value

A processing method and a technology of use value, which are applied in the processing field of improving the use value of low-grade tobacco leaves, can solve the problems of uncoordinated sugar-to-alkali ratio, poor flammability of tobacco leaves, and poor intrinsic quality of cut tobacco, and achieve the reduction of raw material cost and high utilization rate of tobacco leaves. , the effect of internal quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

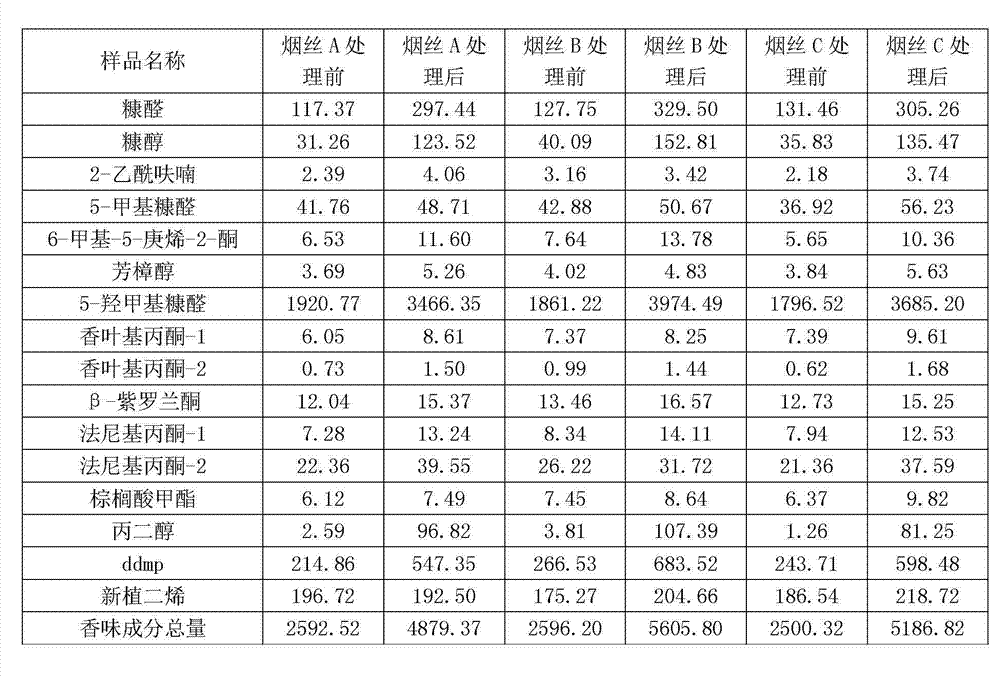

Embodiment 1

[0025] After the single-grade low-grade tobacco leaf A has been moistened once, the moisture content of the tobacco leaves is 18.2%. The moistened tobacco leaves are stored for 6 hours, and the stored tobacco leaves enter the filling machine. %. The moisture content of the added tobacco leaves is 30.1%. Using a burley tobacco roasting machine, the added tobacco leaves are kept at a temperature of 70-110 0 Drying under the condition of C, the processing flow rate of the baking machine is 1600kg / h, and the temperature of the first baking area is 95 0 C, the temperature in the second zone is 90 0 C, the temperature in the third zone is 80 0 C, the temperature in the fourth zone is 65 0 C. To control the moisture content of the tobacco leaves in the cooling zone to about 5%, the tobacco leaves in the cooling zone enter the moisture resurgence zone, and the temperature in the moisture recovery zone 1 is 55 0 C, the temperature in the second zone of resurgence is 50 0 C, the mo...

Embodiment 2

[0031] After the single-grade low-grade tobacco leaf B has been moistened once, the moisture content of the tobacco leaves is 21.5%. The moistened tobacco leaves are stored for 4 hours, and the stored tobacco leaves enter the filling machine. %. The moisture content of the added tobacco leaves is 30.1%. Using a burley tobacco roasting machine, the added tobacco leaves are kept at a temperature of 70-110 0 Drying under the condition of C, the processing flow rate of the roasting machine is 1600kg / h, the temperature of the first roasting zone is 110°C, the temperature of the second zone is 110°C, the temperature of the third zone is 90°C, the temperature of the fourth zone is 80°C, and the moisture content of the tobacco leaves in the cooling zone The control is about 6%, the tobacco leaves in the cooling zone enter the resurgence zone, and the temperature in the resurgence zone is 54 0 C, the temperature in the second zone of resurgence is 56 0 C, the moisture content of the ...

Embodiment 3

[0036] After single-grade low-grade tobacco leaf C has been moistened once, the moisture content of the tobacco leaves is 19.3%. The moistened tobacco leaves are stored for 3 hours. The stored tobacco leaves enter the filling machine. %. The moisture content of the added tobacco leaves is 29.1%. Using a burley tobacco roasting machine, the added tobacco leaves are kept at a temperature of 70-110 0 Drying under the condition of C, the flow rate of the baking machine is 1600kg / h, the temperature of the first baking zone is 85°C, the temperature of the second zone is 85°C, and the temperature of the third zone is 90 0 C, the temperature in the fourth zone is 80 0 C. To control the moisture content of the tobacco leaves in the cooling zone to about 7%, the tobacco leaves in the cooling zone enter the resurgence zone, and the temperature in the resurgence zone 1 is 52 0 C, the temperature in the second zone of resurgence is 58 0 C, the moisture content of the tobacco leaves afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com