Reaction type asphalt regenerating agent and preparation method thereof

An asphalt rejuvenating agent and reaction-type technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of poor road performance of recycled asphalt mixture, short service life of recycled asphalt pavement, and unfavorable long-term storage of polymers. , to achieve the effect of low cost of use, extended service life, and good ductility recovery effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

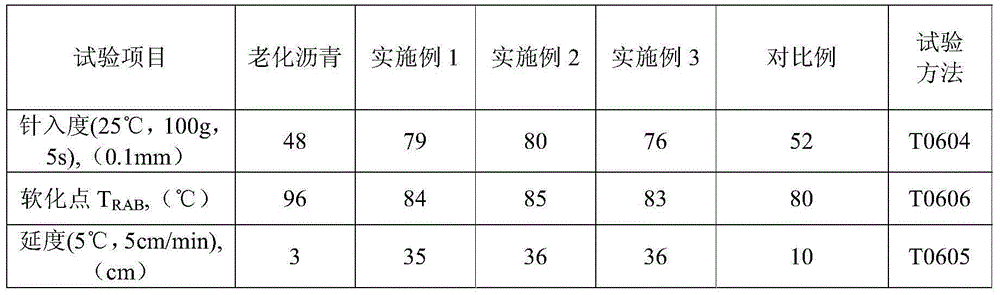

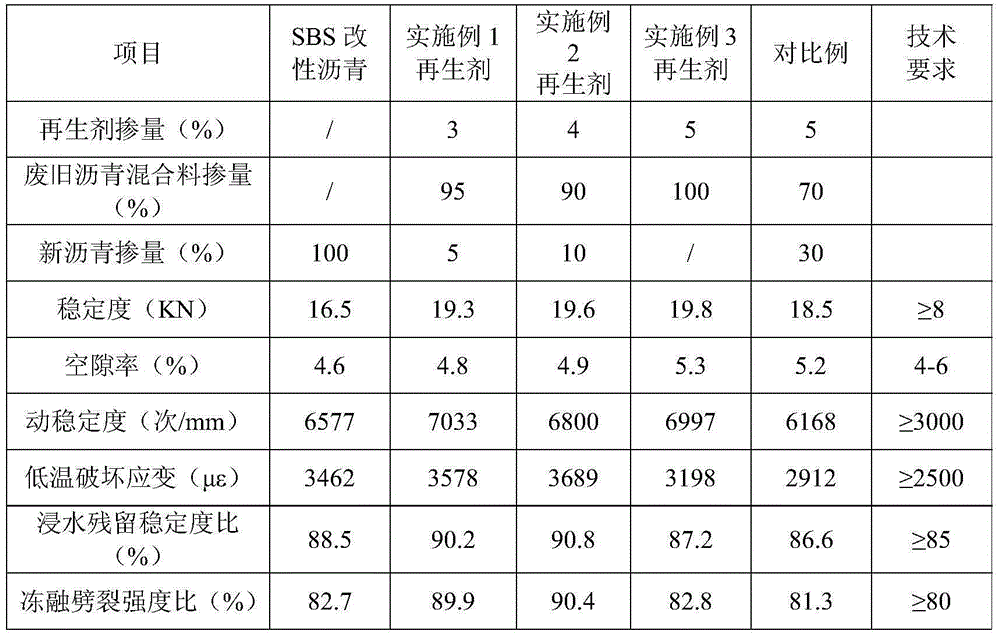

Embodiment 1

[0027] The preparation of polyurethane prepolymer: with 10 parts of polyoxypropylene polyols (with propylene glycol as initiator, potassium hydroxide is catalyzer, molecular weight is 2000, and hydroxyl value is 56mgKOH / g, water content is 0.06wt%), at temperature 110~120℃, vacuum degree -0.08~-0.1MPa, after vacuum dehydration reaction for 2 hours, start to cool down, keep vacuuming during the cooling process, when the system temperature drops to 70~80℃, continue to add 3.22 parts of MDI-50 to In the reaction container, react for 2-4 hours, stop the reaction to obtain the polyurethane prepolymer.

[0028] Add 70 parts of 160# petroleum asphalt, 12 parts of maleic anhydride and 0.01 part of aluminum trichloride into a three-necked flask with a stirring rod and a thermometer, raise the temperature to 160°C for addition reaction for 12 hours, then lower the system temperature to 80°C, Add 13 parts of the polyurethane prepolymer prepared above, 0.1 part of the chain extender 1,4-b...

Embodiment 2

[0030] The preparation of polyurethane prepolymer: with 12 parts of polyoxypropylene polyols (with propylene glycol as starter, with dimethyl carbonate as catalyst, molecular weight is 3000, hydroxyl value is 38mgKOH / g, water content is 0.05wt%), After the dehydration reaction at a temperature of 110-120°C and a vacuum of -0.08--0.1MPa for 2 hours, the temperature began to drop, and the vacuum state was maintained during the cooling process. When the system temperature dropped to 70-80°C, continue to add 4.69 parts of MDI-100 In the reaction container, react for 2 to 4 hours, and stop the reaction to obtain the polyurethane prepolymer.

[0031]Add 45 parts of 110# petroleum asphalt, 21 parts of 90# petroleum asphalt, 15 parts of maleic anhydride and 0.02 part of zinc chloride into a three-necked flask with a stirring rod and a thermometer, raise the temperature to 170 ° C for 10 hours of addition reaction, and then lower When the temperature of the system reaches 70°C, add 15 ...

Embodiment 3

[0033] The preparation of polyurethane prepolymer: with 15 parts of polyoxypropylene polyols (with propylene glycol as initiator, potassium hydroxide is catalyzer, molecular weight is 1000, and hydroxyl value is 112mgKOH / g, water content is 0.03wt%), at temperature 110~120℃, vacuum degree -0.08~-0.1MPa, after dehydration reaction for 2 hours, start to cool down, keep vacuuming during the cooling process, when the system temperature drops to 70~80℃, continue to add 3 parts of MDI-100 and 1 Put one part of MDI-50 in the reaction container, react for 2-4 hours, and stop the reaction to obtain the polyurethane prepolymer.

[0034] Add 74.3 parts of 130# petroleum asphalt, 10 parts of maleic anhydride and 0.04 parts of boron trifluoride into a three-necked flask with a stirring rod and a thermometer, raise the temperature to 180°C for addition reaction for 8 hours, then lower the system temperature to 80°C, Add 10 parts of the polyurethane prepolymer prepared above, 0.1 part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com