Novel secondary aluminum modifying refiner and method for smelting secondary aluminum by utilizing refiner

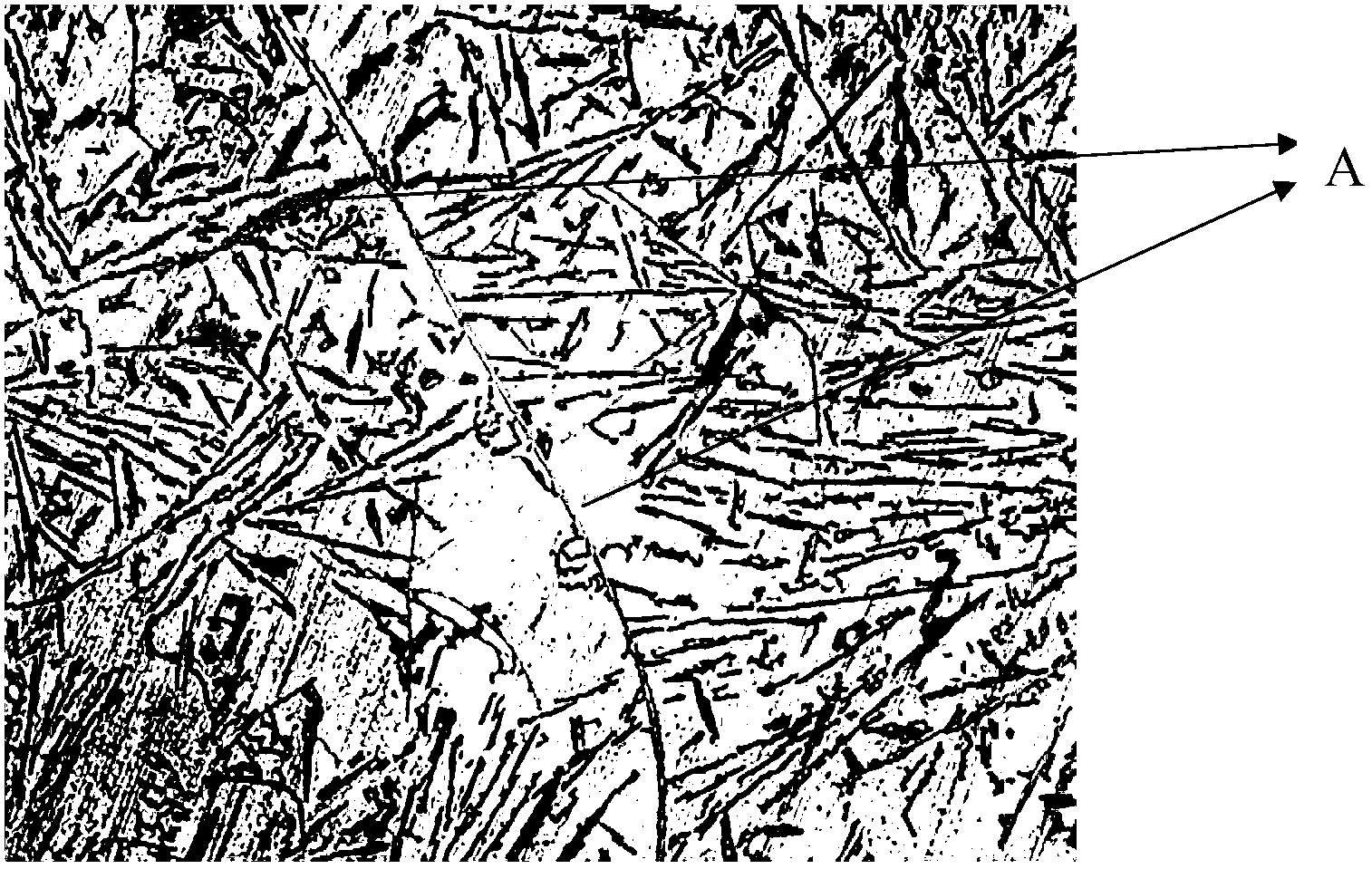

A technology of recycled aluminum and refiner, applied in the direction of improving process efficiency, etc., can solve the problems of reducing the value of alloy elements, not yet discovering public patent documents, and increasing the cost of recycled aluminum, so as to reduce the cost of recycling, improve the quality of recycled products and Performance, effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A new type of secondary aluminum modification refiner and a method for smelting secondary aluminum using the refiner are as follows:

[0062] 1. Prepare Al-Ti-B-Ce-La new type metamorphic refiner, the total feed is 1000kg.

[0063] ⑴ Put the weighed industrial pure aluminum, K 2 TiF 6 , KBF 6 , AlCe10 alloy and AlLa10 alloy are placed in a constant temperature preheated drying oven at 250°C for 2.5 hours.

[0064] (2) Add 542kg of industrial pure aluminum into the 1 ton experimental furnace, set the furnace temperature to 800℃, and ignite and increase the temperature.

[0065] ⑶When the industrial pure aluminum is heated to 800℃ after melting, add 192kg K 2 TiF6, 116kg KBF 6 , Stir fully and keep warm for about one hour to ensure TiAl 3 , TiB 2 The particles are more uniformly dispersed in the melt.

[0066] ⑷Add 75kg AlCe10 alloy and 75kg AlLa10 alloy, stir at regular intervals to make the rare earth elements evenly distributed in the melt, let it stand for 30 minutes, when the ...

Embodiment 2

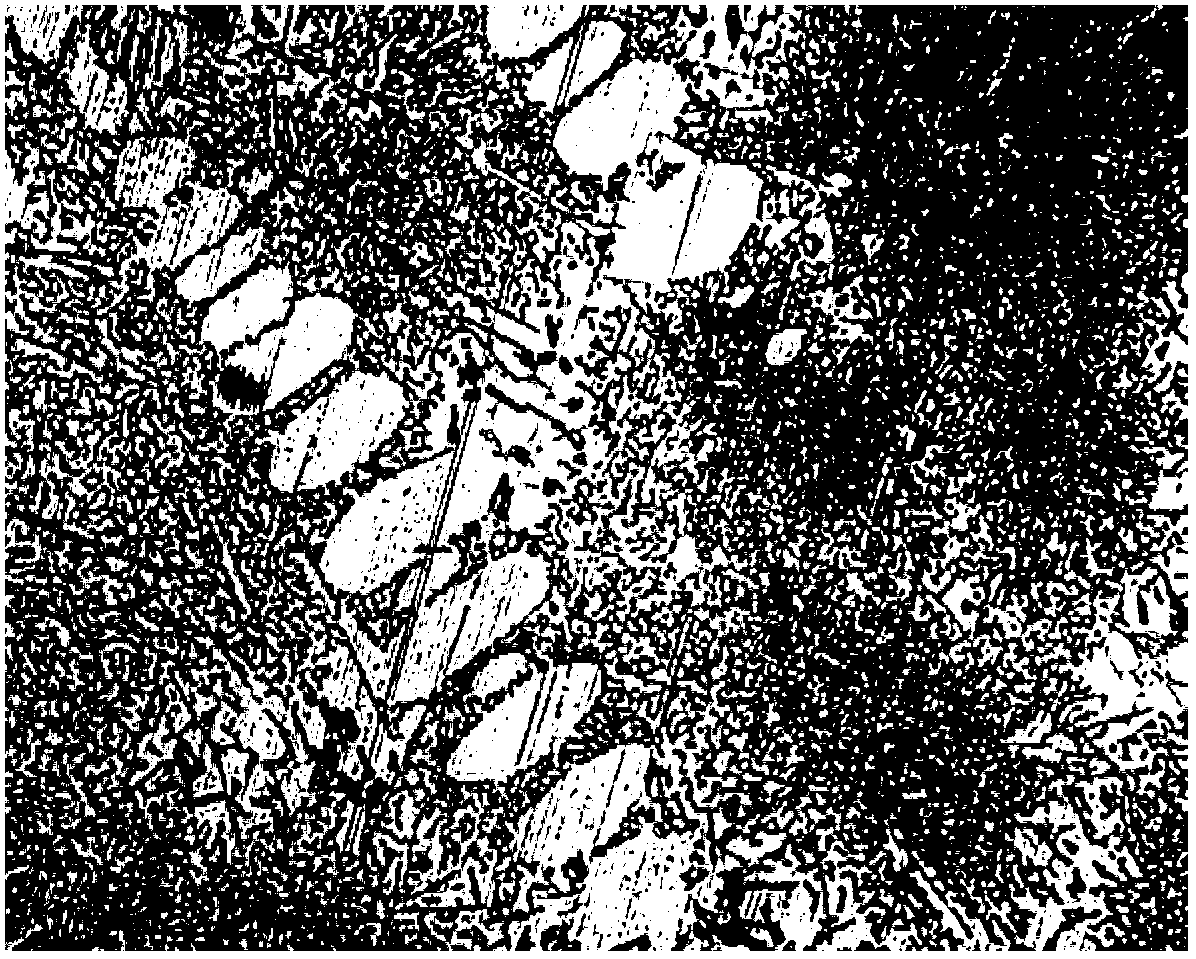

[0078] A new type of secondary aluminum modification refiner and a method for smelting secondary aluminum using the refiner are as follows:

[0079] 1. Preparation of Al-Ti-B-Ce-La new type metamorphic refiner, total feed 800kg.

[0080] ⑴ Put the weighed industrial pure aluminum, K 2 TiF 6 , KBF 6 , AlCe10 alloy and AlLa10 alloy are placed in a constant temperature preheated drying oven at 250°C for 2.5 hours.

[0081] ⑵ Add 433kg of industrial pure aluminum into the 1 ton experimental furnace, set the furnace temperature to 800℃, and ignite and raise the temperature.

[0082] ⑶When the industrial pure aluminum is melted and heated to 800℃, add 154kgK 2 TiF6, 93kgKBF 6 , Stir fully and keep warm for about one hour to ensure TiAl 3 , TiB 2 The particles are more uniformly dispersed in the melt.

[0083] ⑷Add 60kg AlCe10 alloy and 60kg AlLa10 alloy, stir at regular intervals to make the rare earth elements evenly distributed in the melt, and let it stand for 30 minutes. When the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com