Patents

Literature

33results about How to "Effective content control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

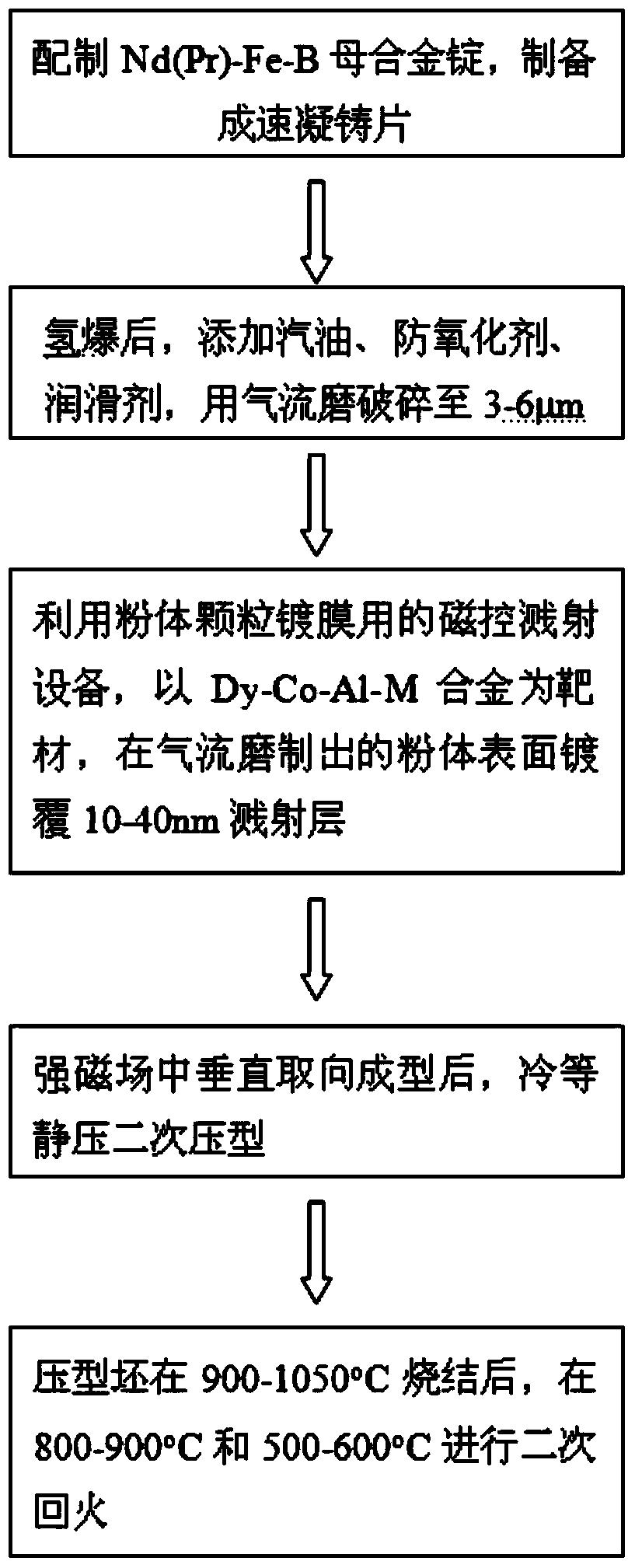

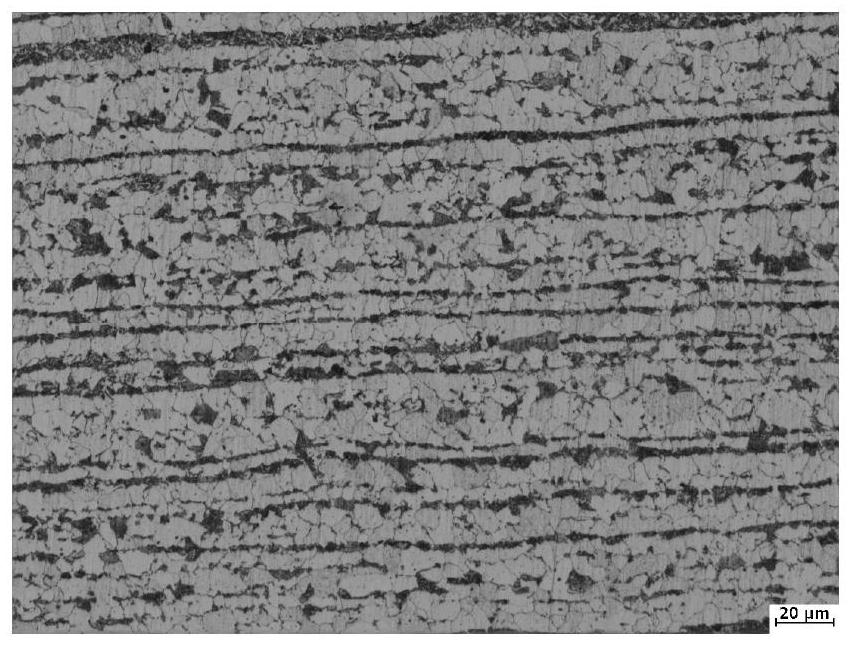

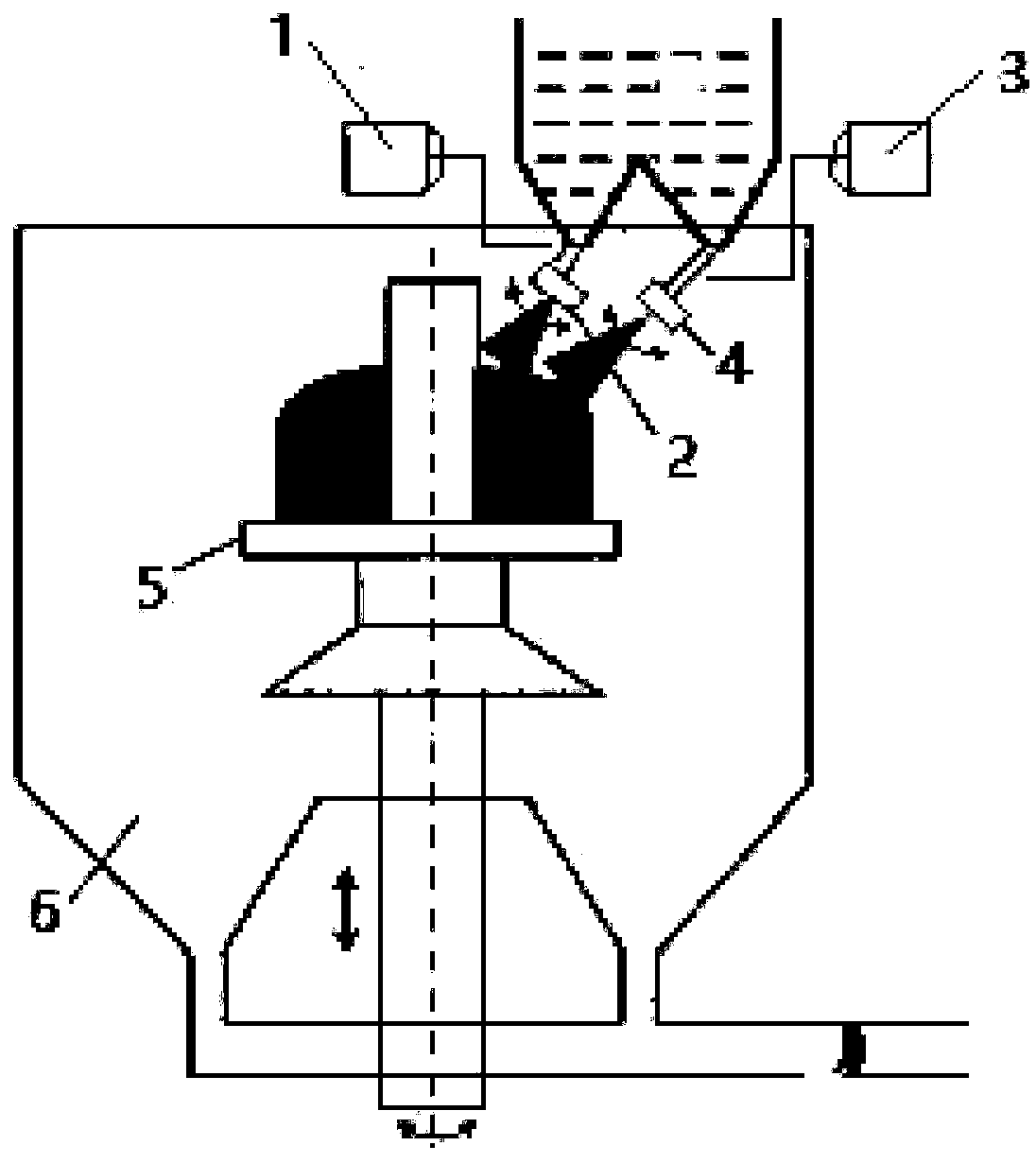

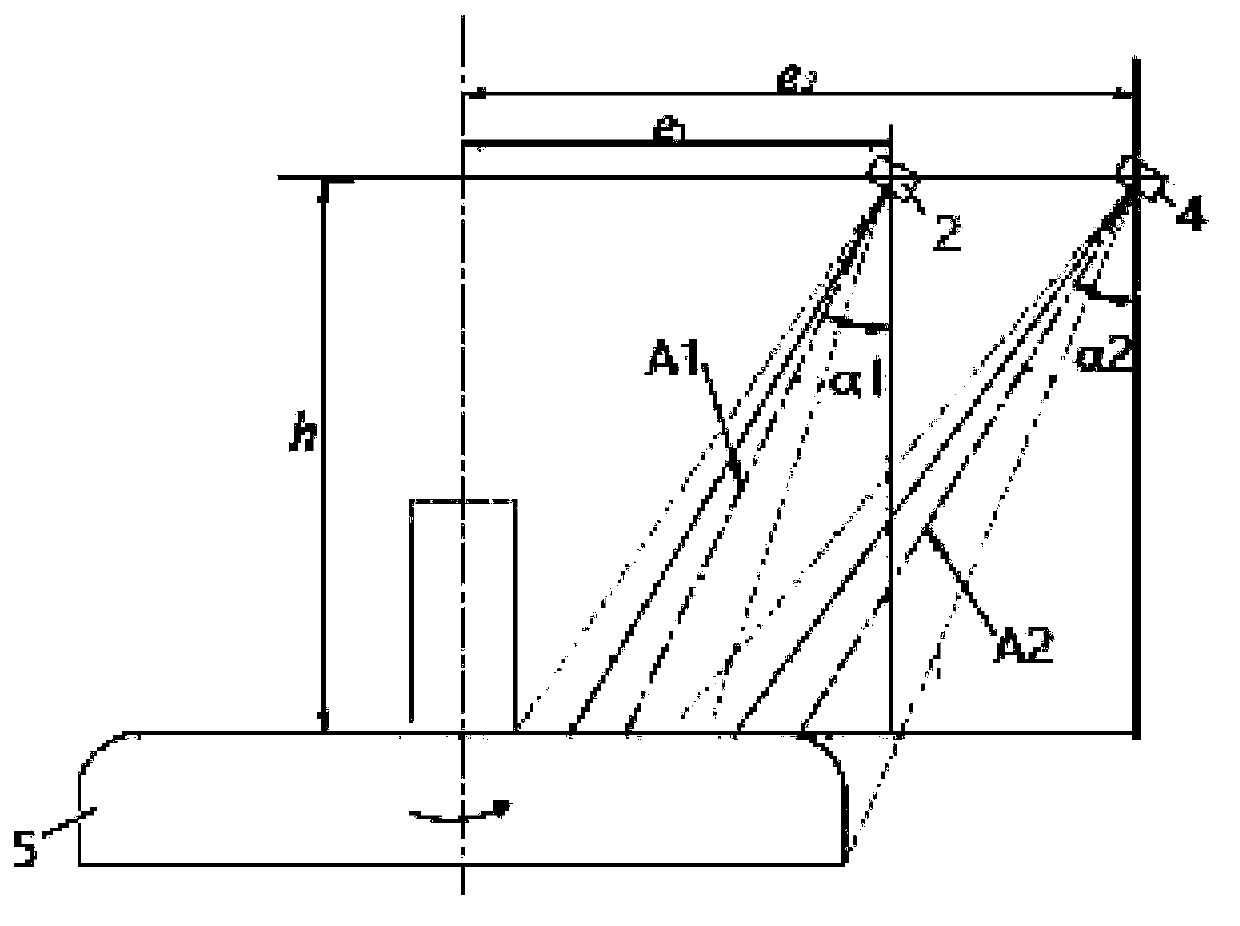

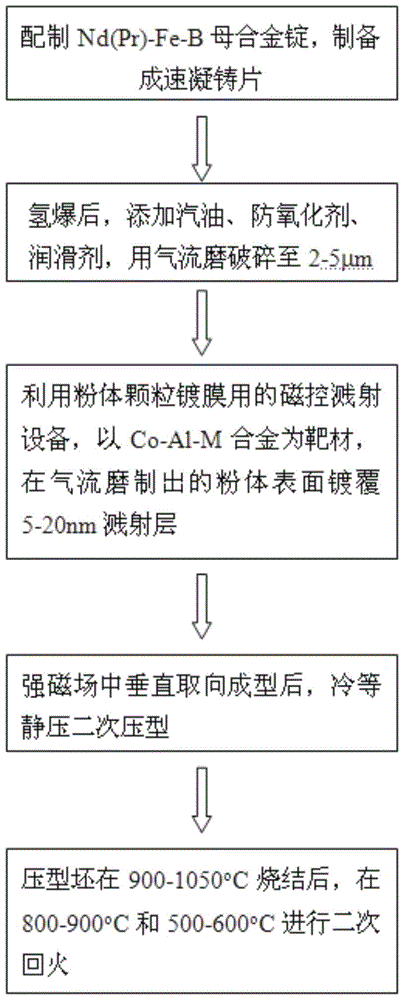

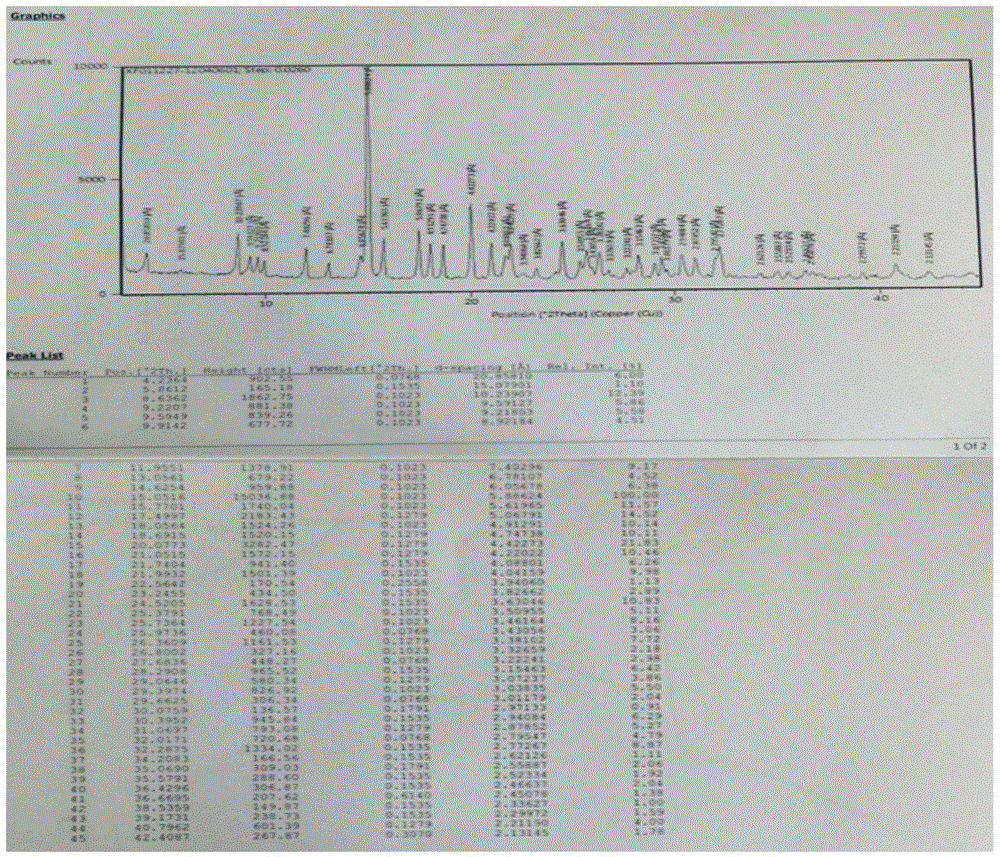

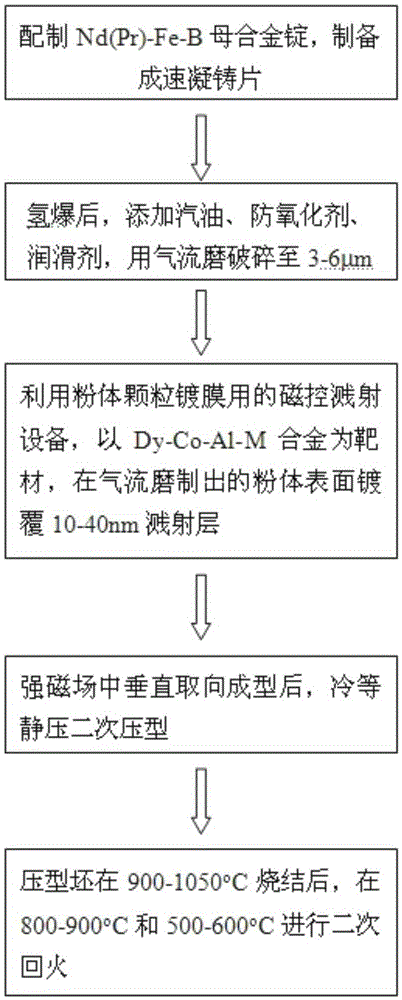

Preparation method of low-dysprosium corrosion-resistant sintering neodymium iron boron

ActiveCN103456452AEffective content controlImprove corrosion resistanceVacuum evaporation coatingSputtering coatingAlloy elementCorrosion resistant

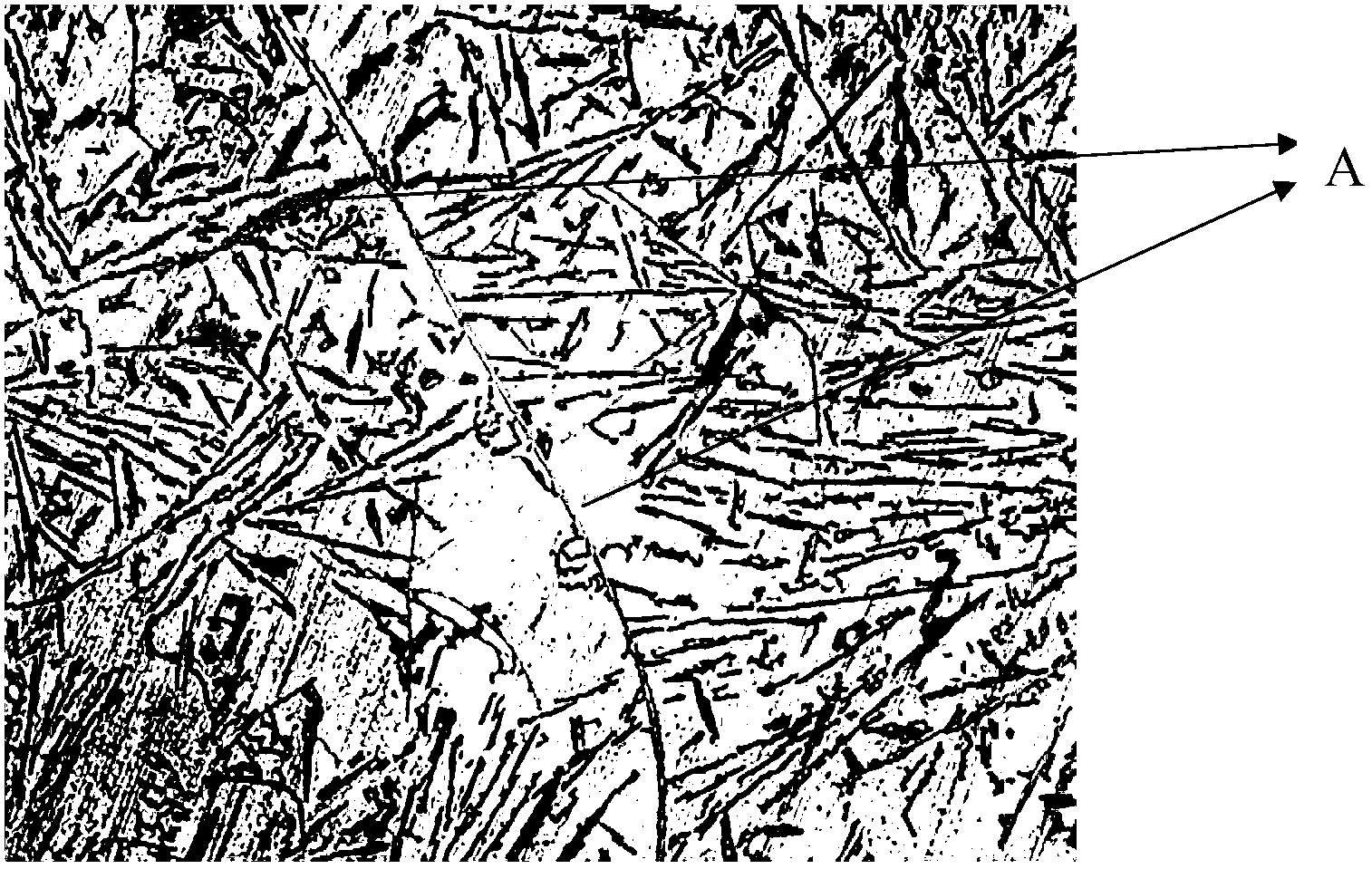

The invention discloses a preparation method of low-dysprosium corrosion-resistant sintering neodymium iron boron. According to the preparation method, Dy, Co, Al and alloy elements such as Cu, Ga and Nb are sputtered on the surface of airflow grinding powder by utilizing a magnetron sputtering-based powder coating process on the basis of preparing Nd(Pr)-Fe-B alloy powder, crystal boundary modified elements such as Co, Al, Cu, Ga and Nb are introduced while the Dy element is introduced into crystal boundary, and the temperature of the subsequent heat treatment process is reduced, so that the alloyed elements are dispersed properly near the crystal boundary in a sintering process, coercivity is improved, the Dy content is reduced, the corrosion resistance of a magnet is effectively improved, and preparation of the low-dysprosium corrosion-resistant sintering neodymium iron boron is realized.

Owner:NANJING UNIV OF SCI & TECH +1

Novel secondary aluminum modifying refiner and method for smelting secondary aluminum by utilizing refiner

ActiveCN103173643AImprove organizational structureIncrease usage ratioProcess efficiency improvementSlagIngot

The invention relates to a novel secondary aluminum modifying refiner and a method for smelting secondary aluminum by utilizing the refiner. The method for producing the secondary alumium by utilizing the refiner specifically comprises the following steps: putting weighed industrial pure aluminum, industrial silicon and waste aluminum into a constant-temperature preheating drying furnace of 250 DEG C to dry for 2-3 hours; conveying dried raw materials into a melting furnace, and removing gas and slag after complete melting; adding 0.3wt%-0.5wt% of novel secondary aluminum modifying refiner when the temperature reaches 730-750 DEG C, fully stirring and standing, detecting and regulating the components; and (5) casting ingots when the temperature is 680-720 DEG C to prepare the secondary aluminum. The novel modifying refiner provided by the invention not only can effectively control the content of impurity elements but also can fully utilize interaction effect between the elements to realize the benefits of the impurity elements, thereby greatly reducing the relegation and regeneration cost and improving the quality and performance of the regenerated products.

Owner:天津新立中合金集团有限公司

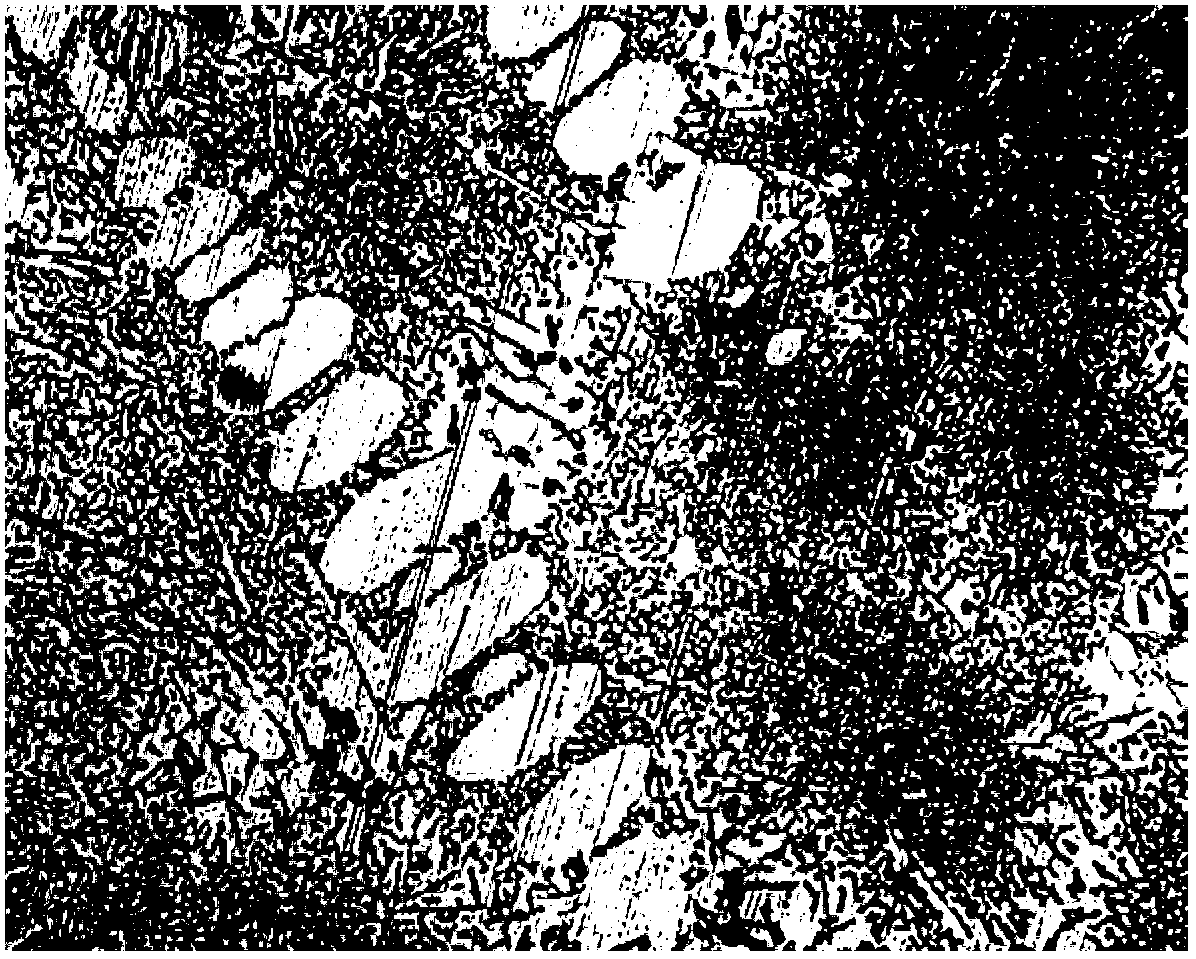

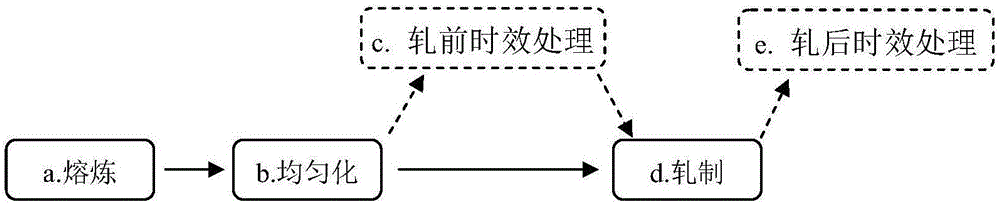

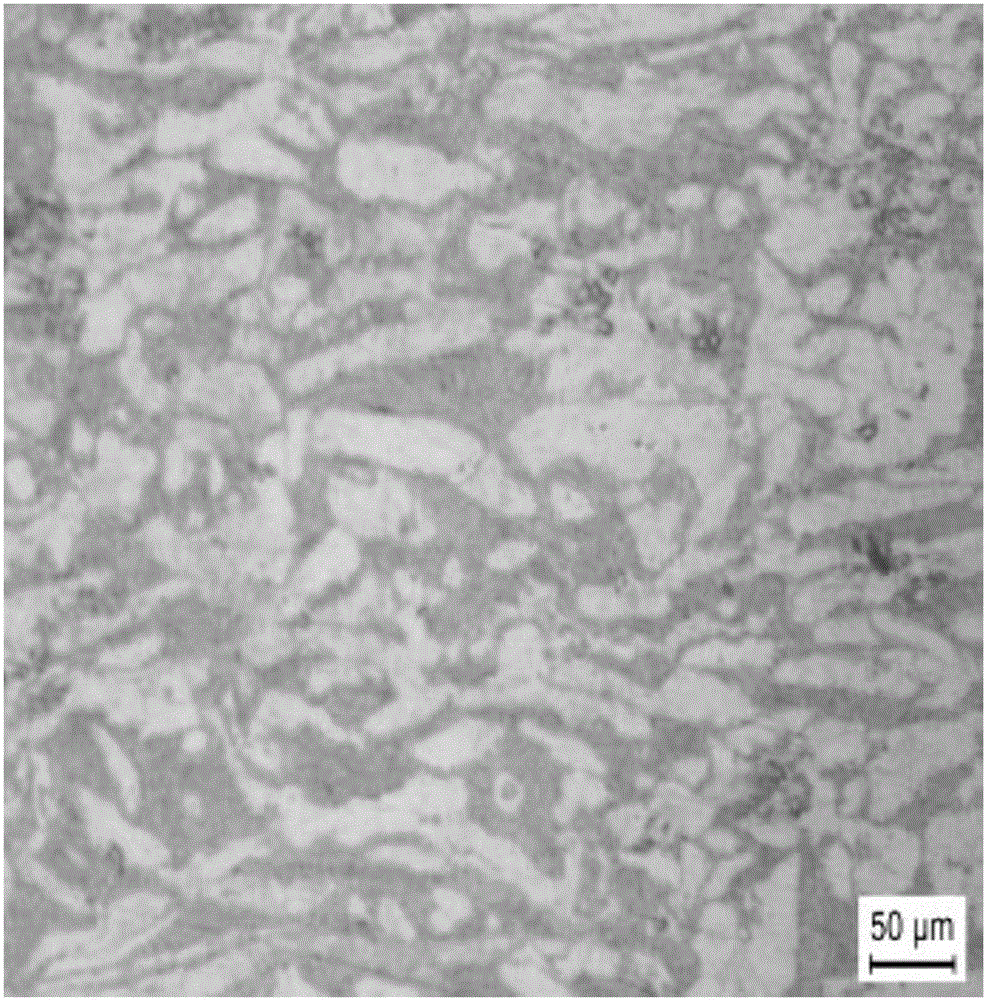

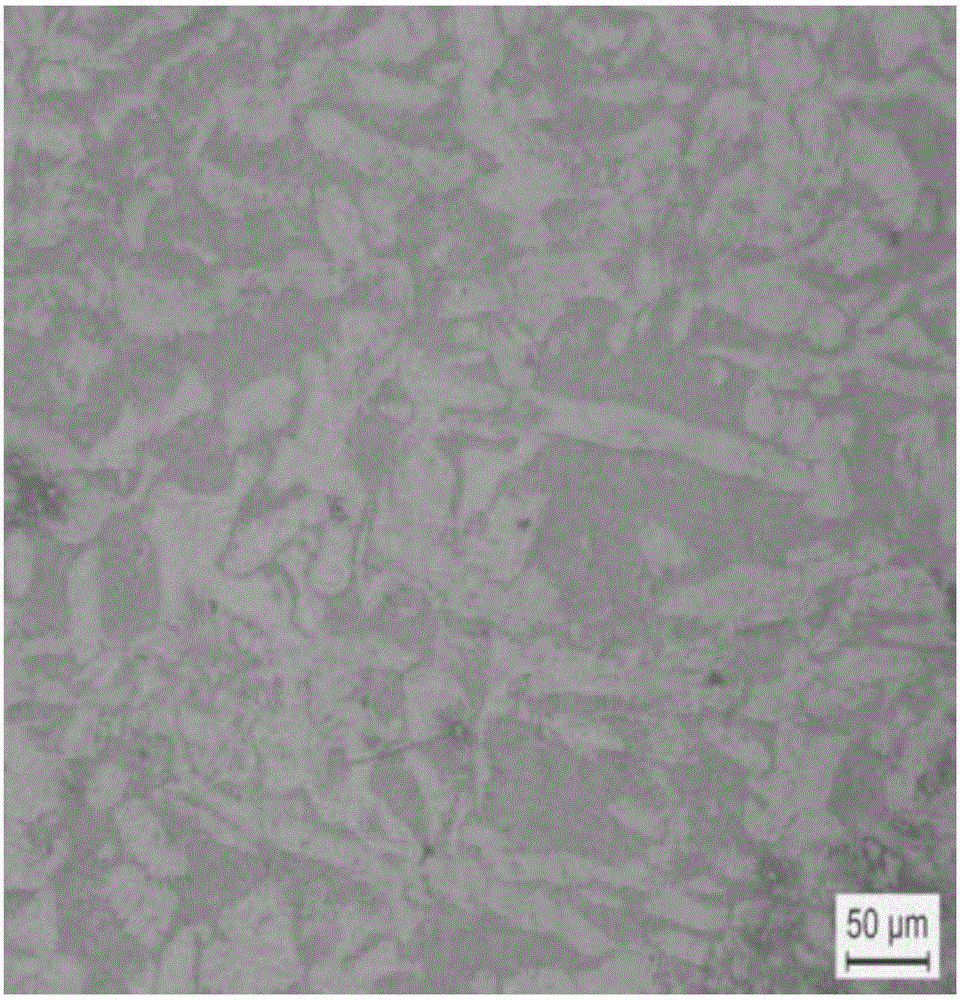

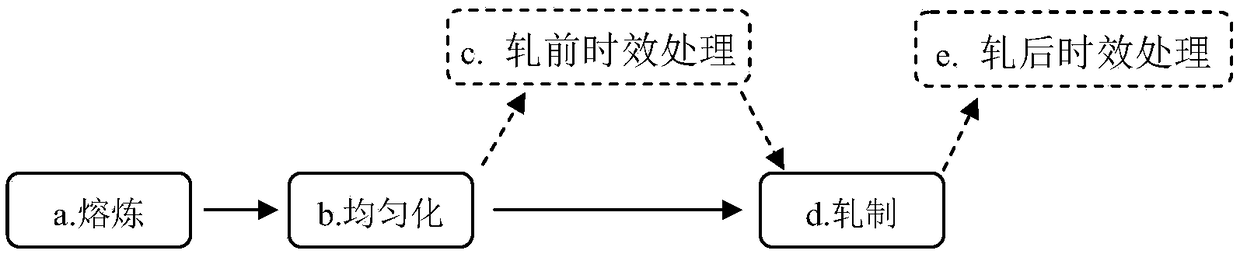

Erbium strengthened magnesium-lithium alloy and preparation method thereof

The invention provides erbium strengthened magnesium-lithium alloy and a preparation method thereof. The magnesium-lithium alloy prepared through the following method comprises, by mass, 5%-11% of Li, 0.5%-10% of Er, not more than 5% of Al and the balance magnesium and inevitable impurity elements. The preparation method comprises the steps that (1) smelting is conducted under the condition of vacuum or protective atmosphere after component proportioning is designed according to the alloy elements, and then an alloy ingot is poured; (2) homogenization treatment is conducted at the temperature of 200 DEG C-500 DEG C, and the homogenization treatment time is 0.5-10 h; (3) multi-pass rolling is conducted at the temperature of 250 DEG C-400 DEG C, and the total reduction rate is 20%-90%; and (4) two times of aging treatment can also be conducted before and after rolling. According to the erbium strengthened magnesium-lithium alloy and the preparation method thereof, the alloy components, the two times of aging treatment temperature, the treatment time, the cooling process, the hot rolling temperature, the hot rolling passes and the deformation parameters are controlled, so that the grain size of the erbium strengthened magnesium-lithium alloy is refined, and the mechanical property is improved.

Owner:HARBIN ENG UNIV

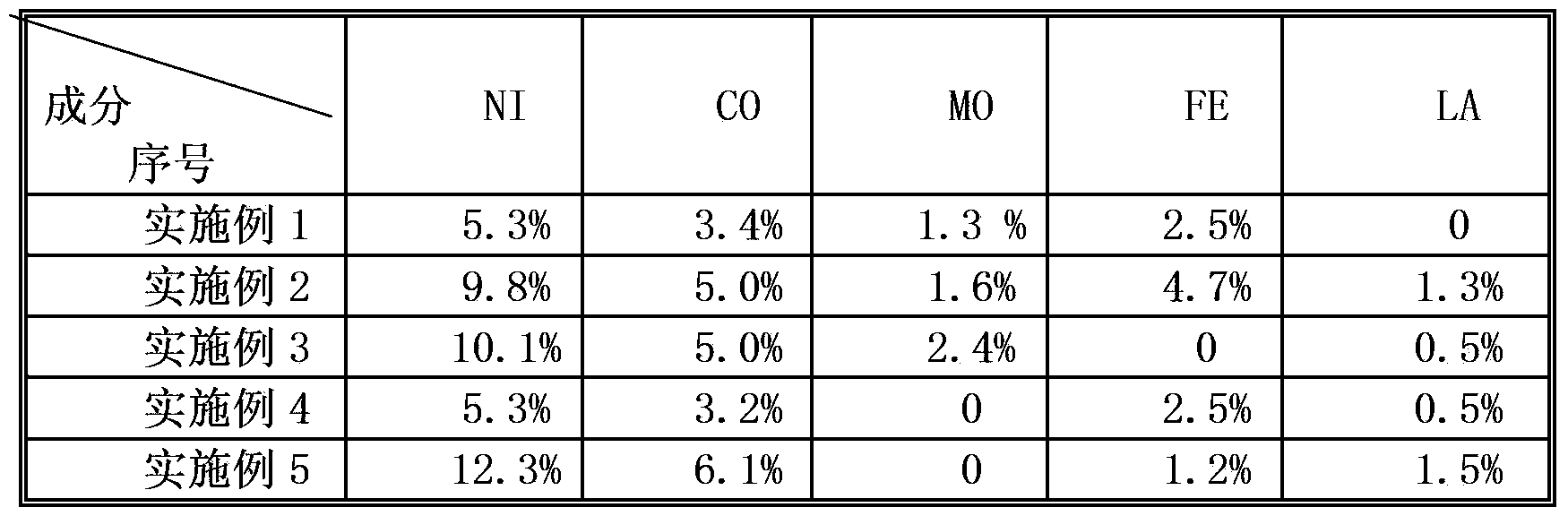

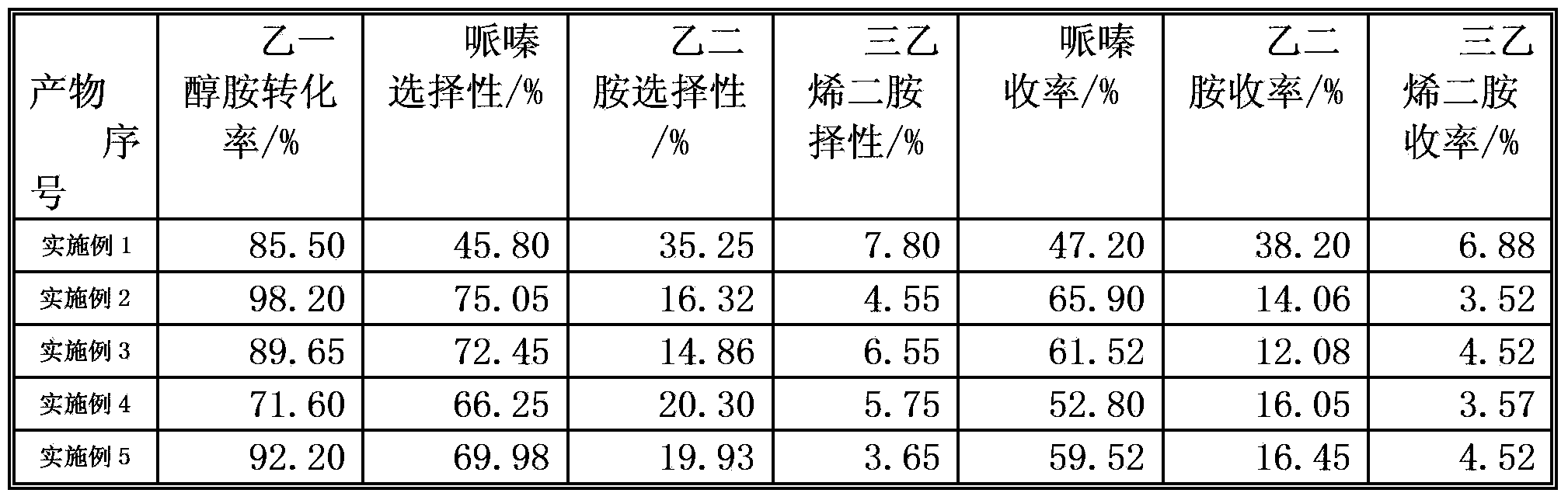

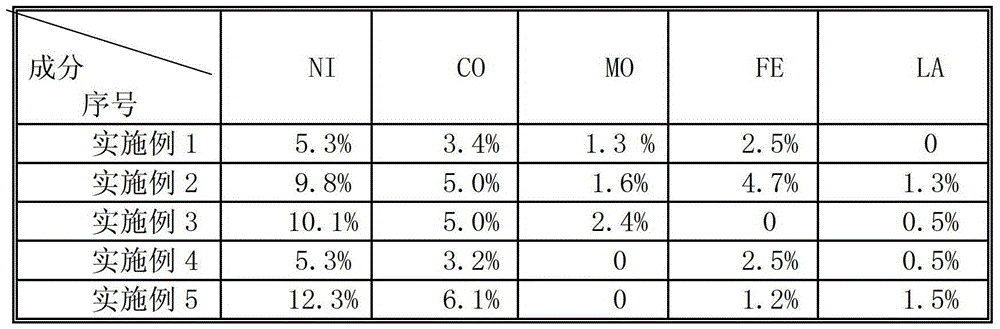

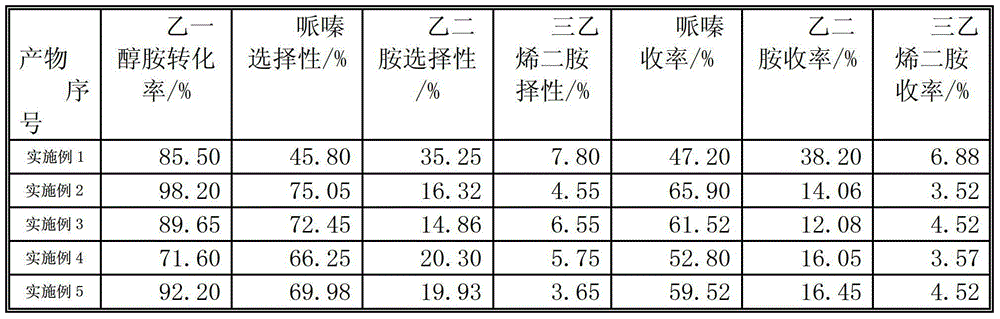

Preparation method of catalyst for synthesizing piperazine through monoethanolamine catalytic amination one-step method

ActiveCN103433050ASimple manufacturing processGuaranteed selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingPiperazine

The invention discloses a preparation method of a catalyst for synthesizing piperazine through a monoethanolamine catalytic amination one-step method. The catalyst is spherical particles prepared by taking a mixture containing gamma-Al2O3 and theta-Al2O3 as a matrix, wherein the specific surface area of the catalyst is 200-300 m<2> / g; the pore volume is 0.45-0.65 cm<3> / g; the particle size is 1.0-3.0 mm. The catalyst mainly comprises the following components: 0-15% of Ni, 0-10% of Co, 0-5% of Mo, 0-10% of Fe, and 0-5% of La. The preparation method of the catalyst comprises the following steps: dipping a carrier for 4.0-12.0 h, then performing dehydration, spraying and performing dehydration, drying, baking, and activating the substance to prepare the spherical particle-like catalyst. The preparation method has the advantages that the solid catalyst for synthesizing piperazine through the monoethanolamine catalytic amination one-step method is prepared; the preparation method of the catalyst adopts a dipping and spraying combined technology, so that the method is simple and convenient to operate; the catalytic medium is free from addition of noble metal, so that the preparation cost of the catalyst is obviously reduced. When the catalyst is used for synthesizing piperazine through the monoethanolamine catalytic amination one-step method, the preparation method has the characteristics of high reaction selectivity and high reaction yield.

Owner:ZHEJIANG LYUKEAN CHEM

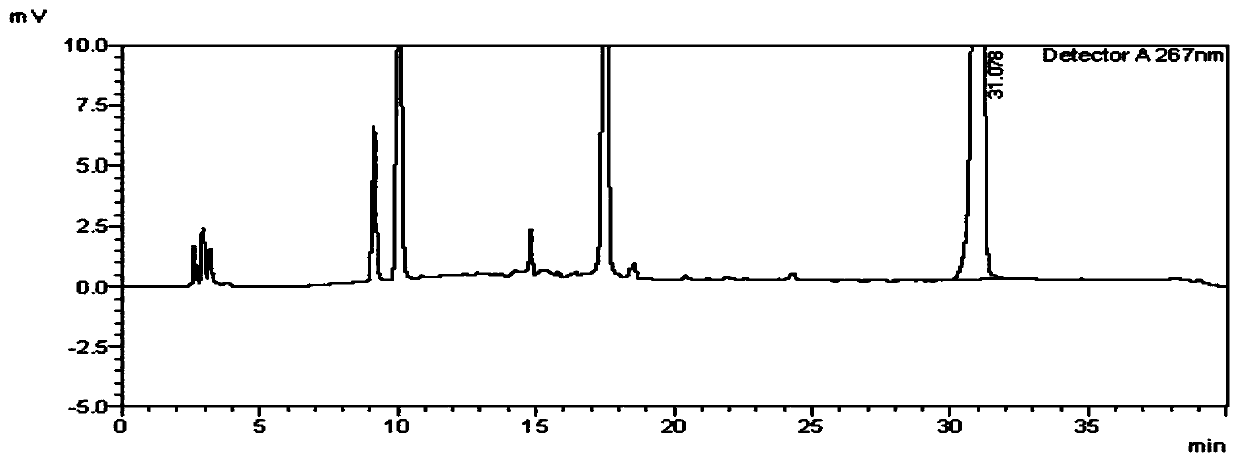

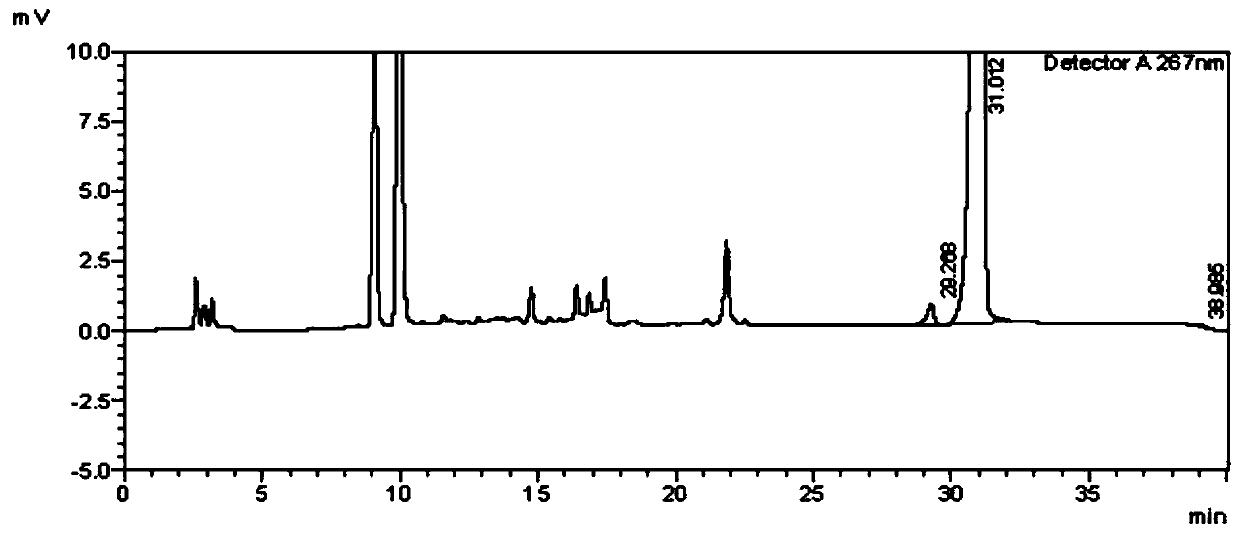

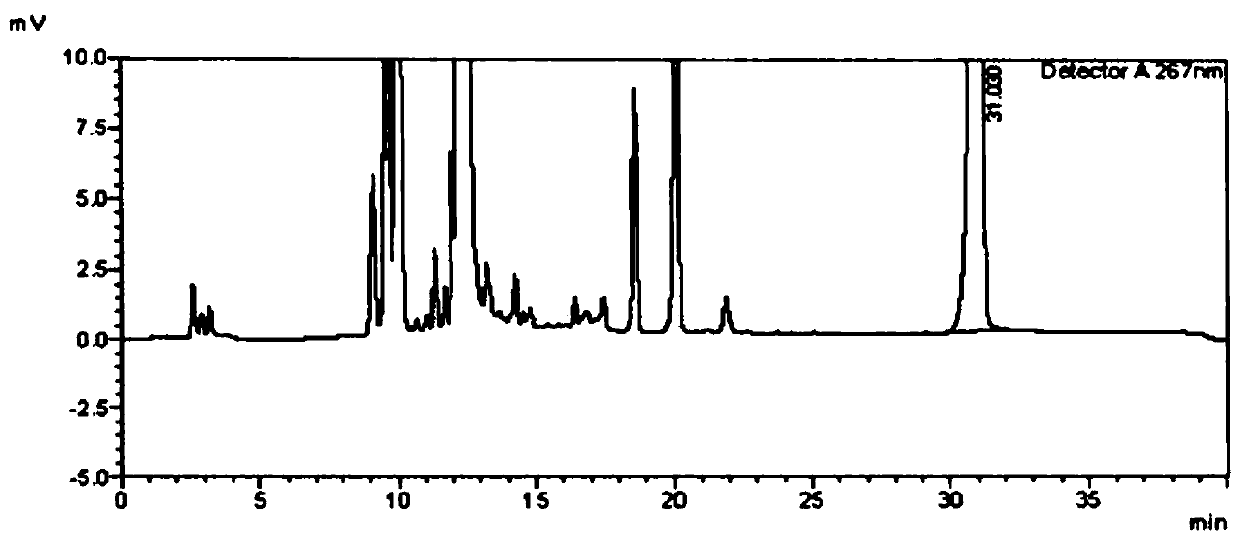

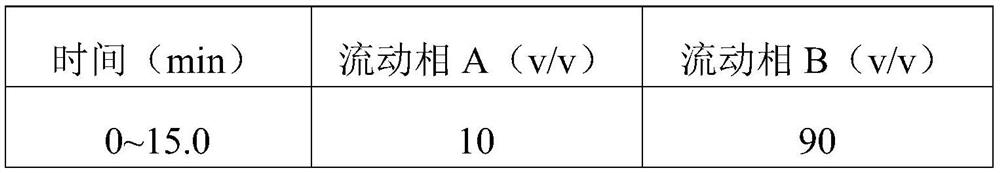

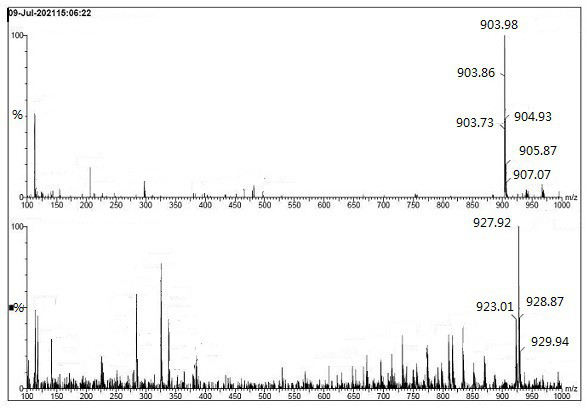

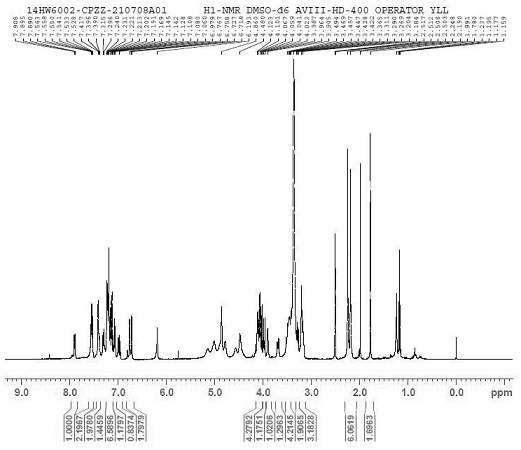

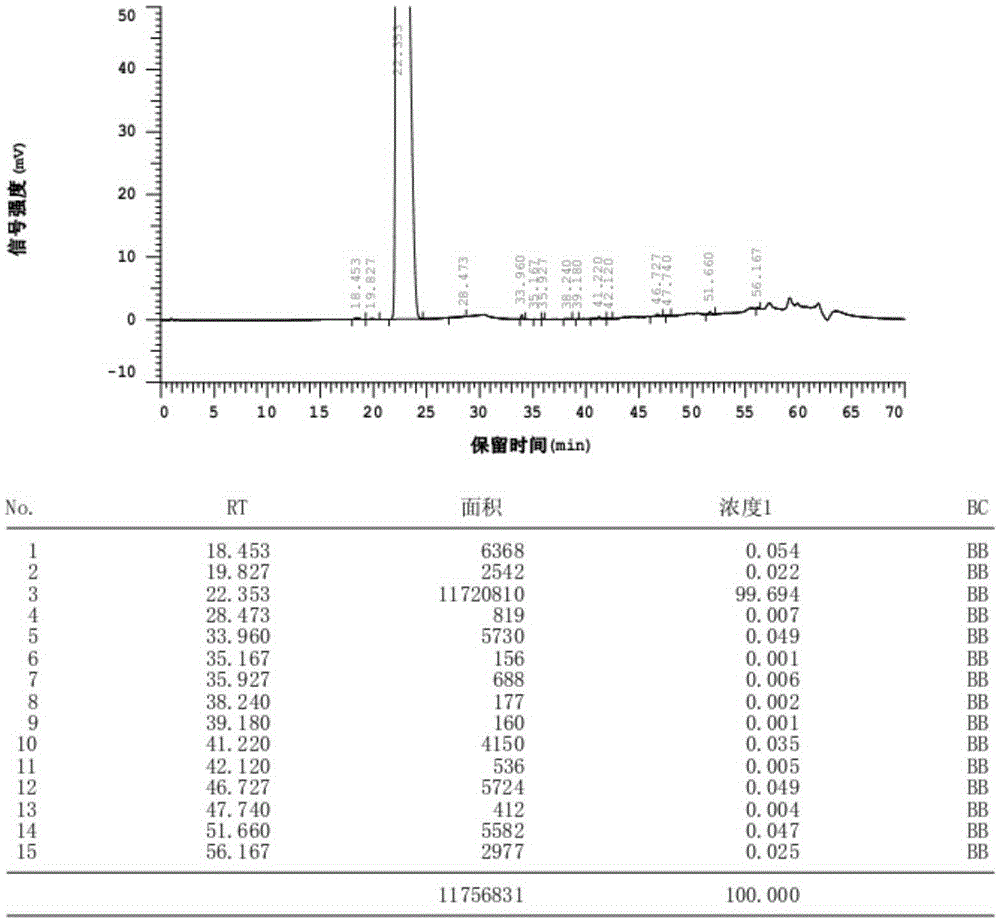

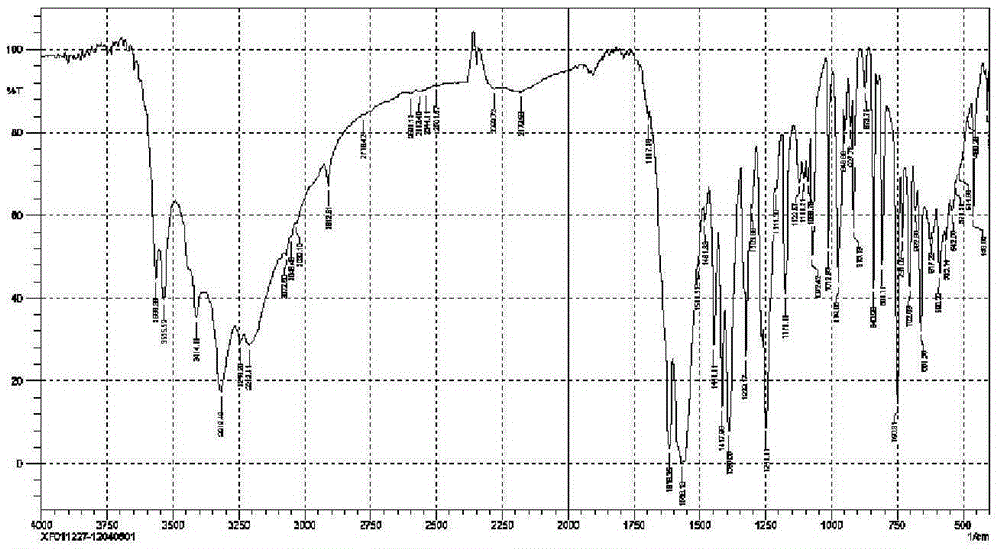

Method for detecting trace genotoxic impurities in voriconazole

The invention discloses a method for detecting trace genotoxic impurities in voriconazole. The method comprises the following steps of carrying out derivatization treatment on a to-be-detected by using biphenyl-4-thiophenol and detecting a genotoxic impurity by adoption of a high performance liquid chromatography, wherein the to-be-detected sample is a raw medicine of voriconazole and the genotoxic impurity is (R / S)-4-(1-Bromoethyl)-5-fluorin-6-chlorine-pyrimidine. The method is not capable of realizing the effective separation of voriconazole and related genotoxic impurities , but also capable of realizing the quantitative detection of trace contents, so as to effectively control the contents of the genotoxic impurities in the raw medicines and ensure the medication safety. By adoption ofcommon agents, the method is convenient to operate, good in separation degree and high in sensitivity. The method is capable of realizing detection through common high performance liquid chromatography without purchasing and combining other instruments, so that the operation is convenient and the detection cost is low.

Owner:WUHAN LL SCI & TECH DEV +2

High-rigidity and low-density novel aluminum-lithium alloy and preparing method thereof

InactiveCN109722570AUniform chemical compositionEffective content controlMaterials scienceRaw material

The invention provides a high-rigidity and low-density novel aluminum-lithium alloy and a preparing method thereof. The high-rigidity and low-density novel aluminum-lithium alloy comprises following metal raw materials including, by mass percent, 3%-6% of lithium, 1%-3.5% of copper, 0.5%-3% of magnesium, 0.1%-0.3% of zirconium and the balance aluminum. Through formula optimization and the preparing method, the tensile strength of the obtained aluminum-lithium alloy can exceed 580 MPa, the yield strength exceeds 610 MPa, ductility exceeds 6%, and density reaches 1.9 g / cm<3>. Chemical componentsare uniform, and casting technology component macrosegregation hardly exists; the content can be effectively controlled; flux coverage is not needed, and flux inclusion is avoided; Ar protection is adopted in the whole process, and oxide inclusion is avoided; casting cold shut and cracking defects are avoided, and the ingot blank heat stress is greatly reduced; spraying forming is uniform, rapidcooling is achieved, and an ingot blank structure is fine and uniform; water cooling is not needed in the whole production process, contact with water is avoided, the problem about casting leakage flow does not exist, and combustion, explosion and other risks are avoided.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

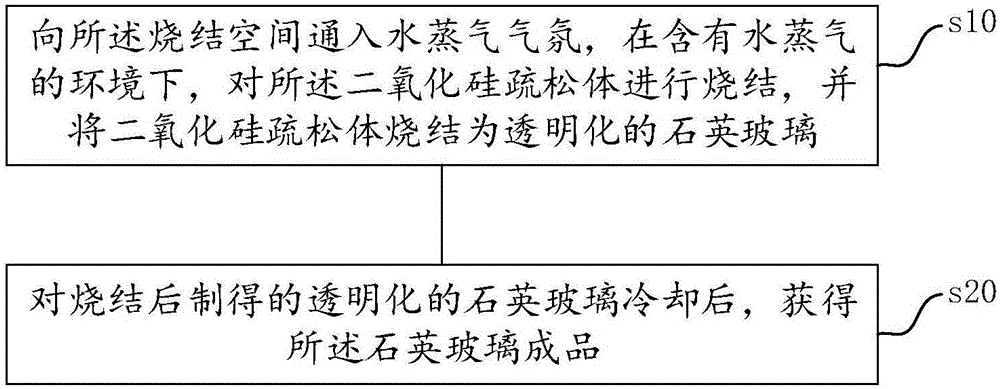

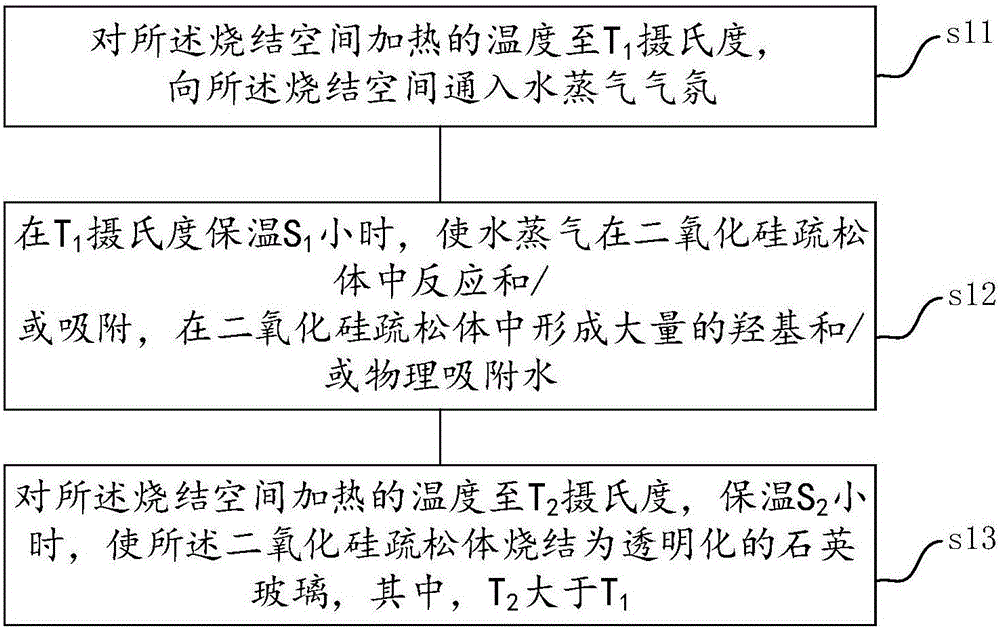

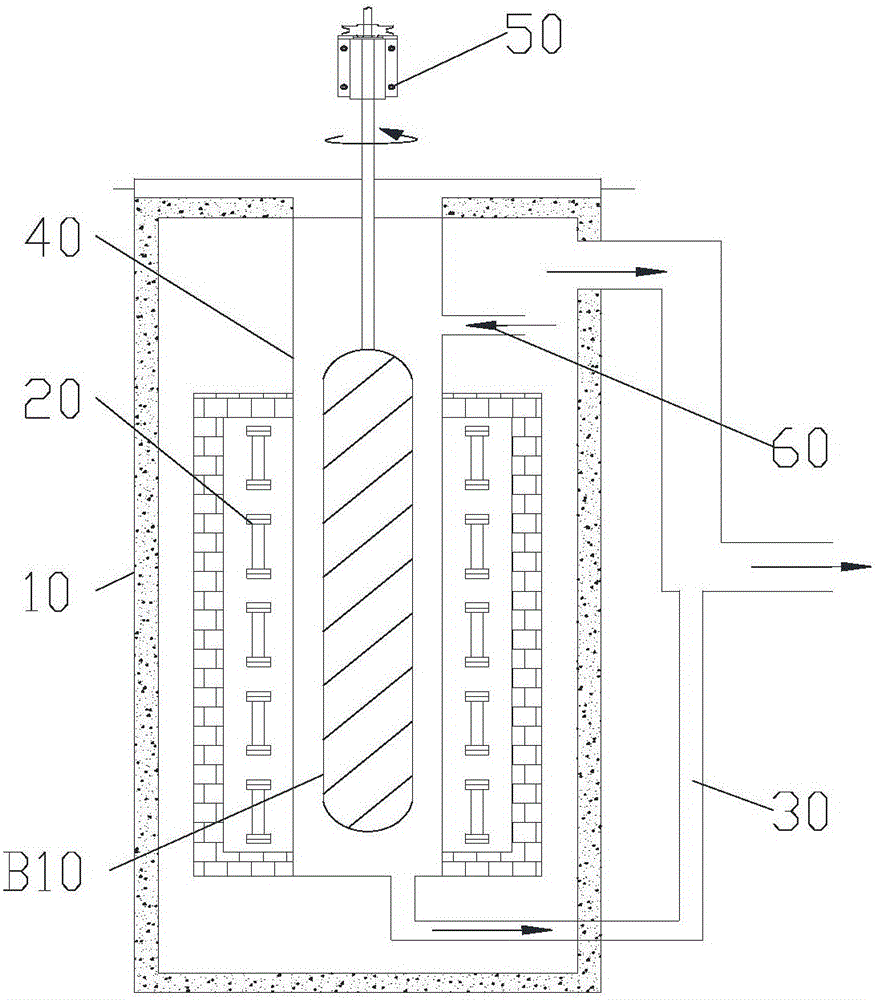

Preparation method of quartz glass and quartz glass

PendingCN106116121AIncrease contentEffective content controlGlass shaping apparatusWater vaporSilicon dioxide

The invention relates to a preparation method of quartz glass and quartz glass, belongs to the field of quartz glass preparation, and mainly aims to realize preparation of quartz glass with controllable hydroxyl content. The preparation method comprises the following steps: injecting steam atmosphere into a sintering space, enabling reaction and / or adsorption of steam in a silicon dioxide loose body in a steam-containing environment to form lots of hydroxyls and / or physically absorbed water in the silicon dioxide loose body, and sintering the silicon dioxide loose body with high hydroxyl content into transparent quartz glass; cooling the transparent quartz glass prepared after sintering to obtain quartz glass end product. The hydroxyl content in the silicon dioxide is effectively controlled by controlling the steam injection flow rate, air pores in the silicon dioxide loose body are removed through sintering the silicon dioxide loose body to prepare the high-quality synthetic quartz glass with controllable hydroxyl content, and the problem that conventional preparation technologies cannot meet the application requirements for different hydroxyl content ranges from quartz glass is solved.

Owner:CHINA BUILDING MATERIALS ACAD

Wear-resistant steel and production method thereof

The invention discloses wear-resistant steel and a production method thereof, and relates to the technical field of steel production, and the wear-resistant steel comprises the following chemical components in percentage by mass: 0.10 to 0.45 percent of C, 0.20 to 0.55 percent of Si, 0.50 to 1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.060 percent of Nb, less than or equal to 0.030 percent of V, 0.008 to 0.025 percent of Ti, 0.20 to 1.00 percent of Cr, less than or equal to 1.80 percent of Ni, less than or equal to 0.50 percent of Mo, 0.025 to 0.055 percent of Al, 0.0010 to 0.0030 percent of B, 0.0010 to 0.0018 percent of Mg, less than or equal to 0.0045 percent of N and the balance of Fe and inevitable impurities. On the premise that the high-strength martensite structure of the wear-resistant steel plate is guaranteed, through quantitative treatment of microalloying elements, the number and the size of carbonitride are reduced, the cooling speed and the austenite temperature of a casting blank are regulated and controlled, a secondary quenching optimization process is adopted, structure grains are refined, structure stress is eliminated, and the wear resistance of the wear-resistant steel plate is improved. The problem of delayed cracks of wear-resistant steel in the cutting and grinding process of casting blanks and steel plates is solved.

Owner:NANJING IRON & STEEL CO LTD

Preparation method for 1420 aluminum lithium alloy hollow ingot blank molded through injection

InactiveCN110722162AUniform chemical compositionEffective control of H contentAdditive manufacturing apparatusMetallic lithiumMetallic aluminum

The invention provides a preparation method for a 1420 aluminum lithium alloy hollow ingot blank molded through injection. The preparation method comprises the following steps that the raw materials of aluminum metal, lithium metal, magnesium metal and zirconium metal are smelted in a primary smelting furnace to form a liquid metal mixed solution; primary deslagging and degassing is carried out; the liquid metal mixed solution is subjected to heat preservation in a tundish, and secondary deslagging and degassing is carried out; in the tundish, the liquid metal mixed solution is atomized in aninert atmosphere to form a particle jet flow, technical parameters of injection equipment are adjusted, the particle jet flow is controlled to be deposited on a substrate at a high speed, and a 1420 aluminum lithium alloy hollow blank material is molded through solidification; the 1420 aluminum lithium alloy hollow blank material molded through injection is naturally cooled, and residual stress iseliminated; and a finished product is obtained through turning and demolding. According to the preparation method, after the aluminum lithium alloy hollow ingot blank is prepared and a correspondinghot working process and a corresponding heat treatment process are carried out, the tensile strength exceeds 490 MPa, the yield strength exceeds 340 MPa, and the elongation percentage is greater than10%.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

A preparation method of room temperature high magnetic energy product corrosion resistant sintered NdFeB

ActiveCN103456451BHigh energy productLow melting pointInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHigh energy

The invention discloses a preparation method of room temperature high magnetic energy product corrosion resistant sintered NdFeB. On the basis of preparing Nd(Pr)-Fe-B alloy powders without heavy rare earth elements such as Dy, using the powder coating process based on magnetron sputtering, Co, Al and Cu, Ga, Nb and other alloying elements At the same time, it is sputtered onto the surface of the airflow mill powder, and the Co and Al elements that increase the electrochemical corrosion potential, the Cu and Nb elements that inhibit the grain growth, and the Ga elements that reduce the melting point of the grain boundary and improve the grain boundary are introduced into the grain boundary. Lowering the temperature of the subsequent heat treatment process inhibits the excessive growth of grains and at the same time makes the alloying elements diffuse moderately near the grain boundaries during the sintering process. The invention obtains high magnetic energy product and excellent corrosion resistance through the control of grain boundary phase ratio and potential, and realizes the preparation of high magnetic energy product corrosion-resistant sintered NdFeB at room temperature.

Owner:NANJING UNIV OF SCI & TECH +1

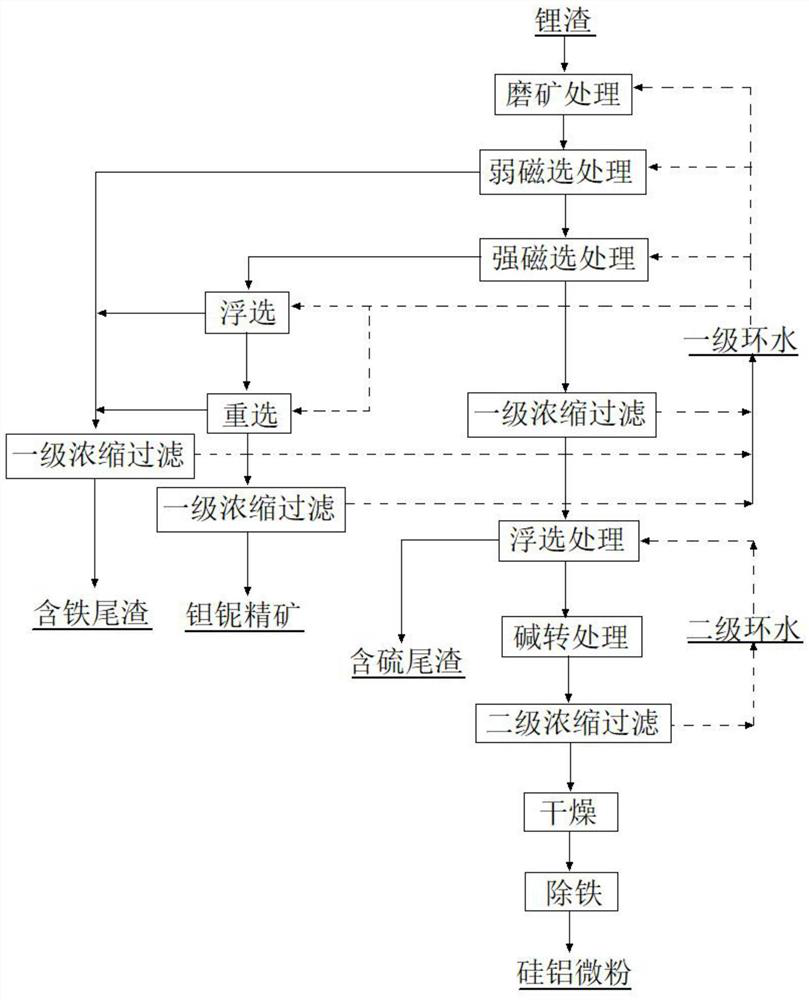

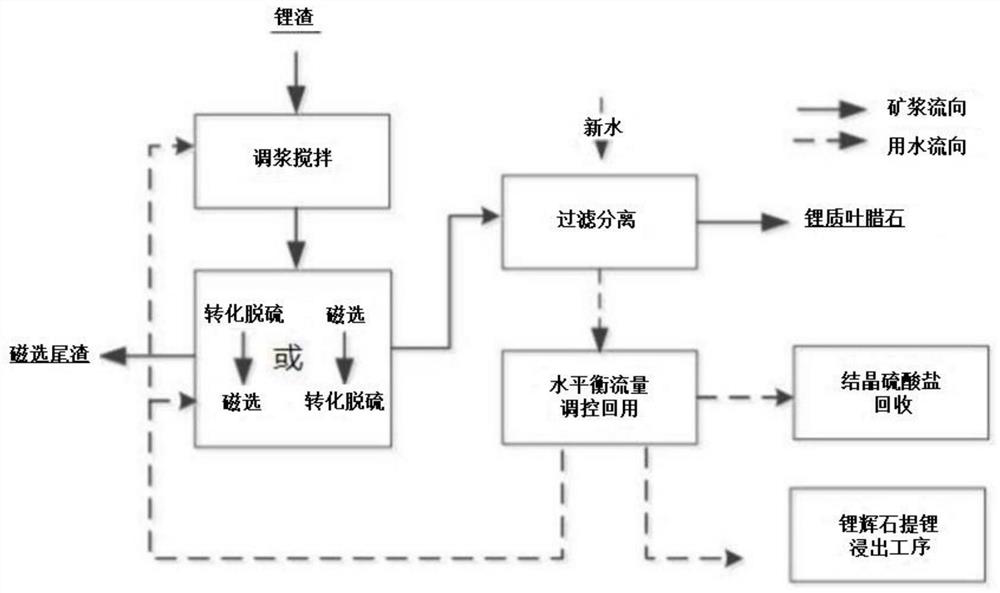

Comprehensive treatment process of lithium slag

ActiveCN114226413AIncrease productionQuality improvementSolid waste disposalProcess efficiency improvementLithiumSlag

The invention discloses a comprehensive treatment process of lithium slag, which is used for comprehensively utilizing waste slag generated after lithium is extracted by a lithium ore sulfuric acid method process by adopting an ore grinding treatment technology, a weak-strong magnetic separation iron removal technology, a solid-liquid two-phase desulfurization technology and a multi-stage circulating water classification circulation technology. According to the method, iron-containing and sulfur-containing impurity components and silicon-aluminum components can be effectively separated, and conditions are created for producing high-added-value products such as silicon-aluminum micro powder and tantalum-niobium concentrate by comprehensively utilizing the lithium slag. And meanwhile, the problems of coarse product granularity, low yield, valuable metal waste, wastewater discharge and the like in the existing production process are solved, and the method has a relatively good popularization and application prospect.

Owner:TIANQI XINLONG CO LTD

Corrosion-resistant rare earth copper alloy

InactiveCN112126816AReduce total usageEffective content controlCemented carbideUltimate tensile strength

The invention discloses a corrosion-resistant rare earth copper alloy, and belongs to the field of copper alloys. The corrosion-resistant rare earth copper alloy is prepared from the following components in percent by mass: 70-75% of Cu, 2.0-4.0% of Al, 3.0-3.5% of Ni, 0.2-1.8% of Si, 0.002-0.060% of Zr, 0.5-0.8% of Re, 1.6-2.0% of Cr, 0.5-1.5% of Fe, 2.5-3.0% of Mn and the balance of Zn and inevitable impurities. The content of the impurities S is controlled to be smaller than or equal to 0.02%, and the content of the impurities P is controlled to be smaller than or equal to 0.02%. The prepared corrosion-resistant rare earth copper alloy is excellent in heat conduction performance, high in strength, good in corrosion resistance and excellent in physical performance. Meanwhile, the copperalloy is easy to machine, can be widely applied to the fields of machining, hard alloys and the like, and has good practical application value. Test results show that compared with common copper alloys, the tensile strength of the corrosion-resistant rare earth copper alloy is improved by 35% or above, and the corrosion resistance is improved by 50% or above.

Owner:绵阳市胜源合金制造有限公司

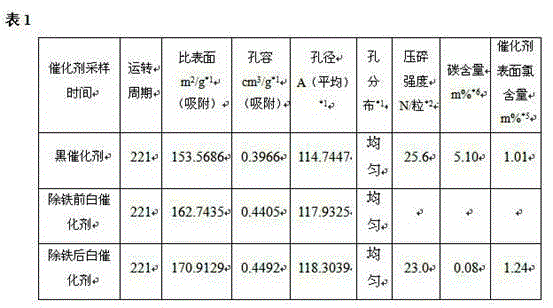

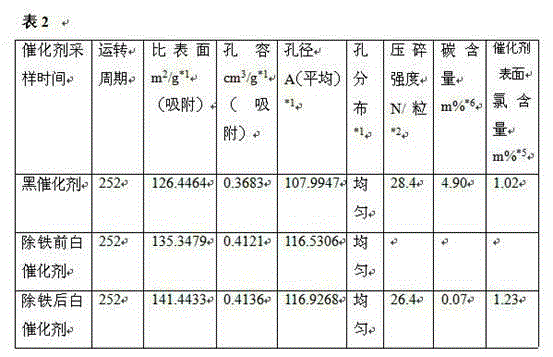

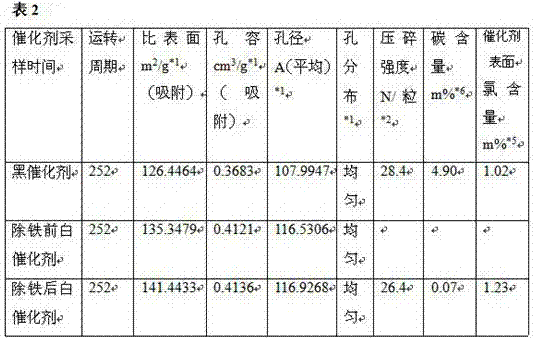

Treatment agent of removing harmful metal elements from surface of catalyst and removal method thereof

ActiveCN104971785AEasy to cleanEfficient removalCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsEnvironmental chemistrySurface-active agents

The invention relates to a treatment agent of removing harmful metal elements from the surface of a catalyst, wherein the treatment agent includes following components, by mass, 0.1-10% of disodium ethylene diamine tetraacetate, 0.1-15% of sulphamic acid or / and sulfosalicylic acid, 0.005-0.1% of aspartic acid or / and polyepoxysuccinic acid, 0.01-0.5% of a surfactant and the balanced being water. The invention also relates to a method of removing the harmful metal elements from the surface of the catalyst with the treatment agent. The method is simple and available. The catalyst can be soaked completely in the treatment agent, so that the harmful metal elements in the catalyst are directly subjected to a chemical reaction with the treatment agent in liquid phase, wherein generated substances are dissolved in the treatment agent, so that the harmful metal elements can be high-effectively removed under the situation of not changing the content and distribution of the active elements on the surface of the catalyst, thereby effectively controlling the content of the harmful metal elements on the surface of the catalyst for maintaining the activity and the catalytic reforming performance of the catalyst.

Owner:SINOPEC YANGZI PETROCHEM +1

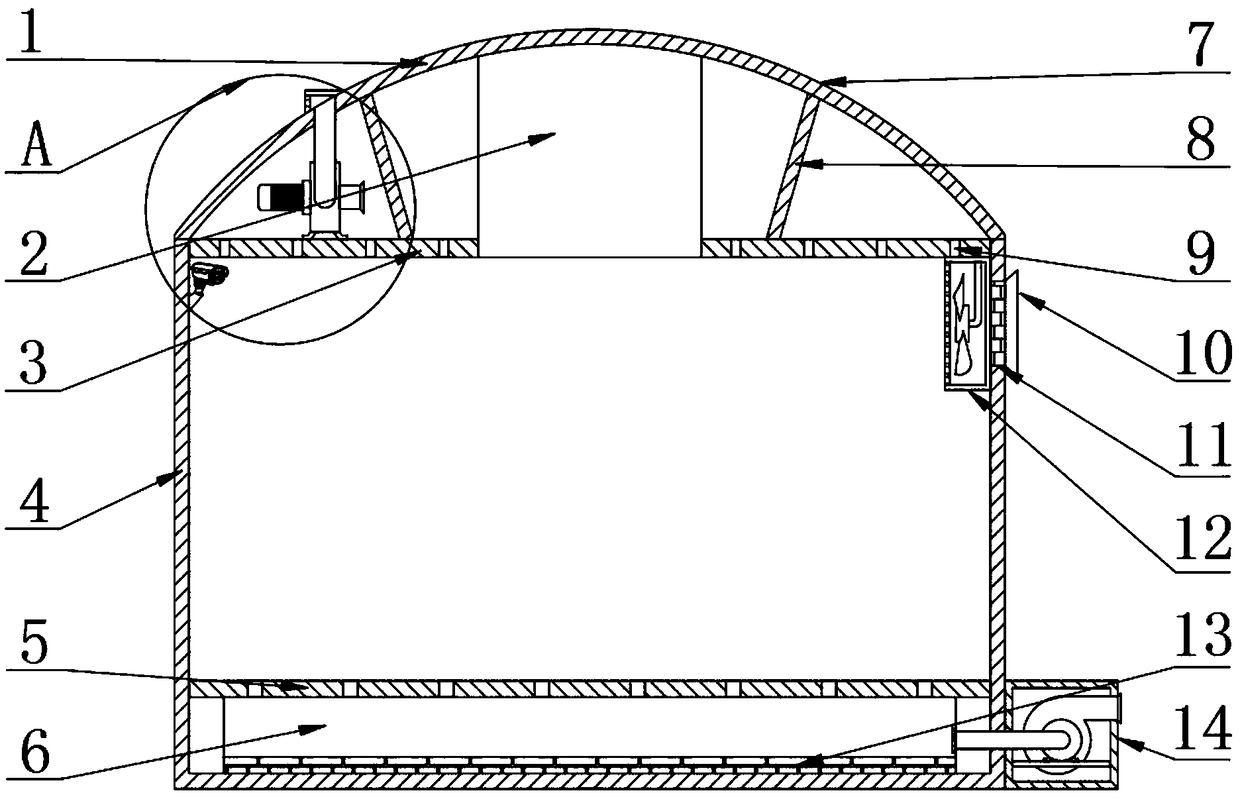

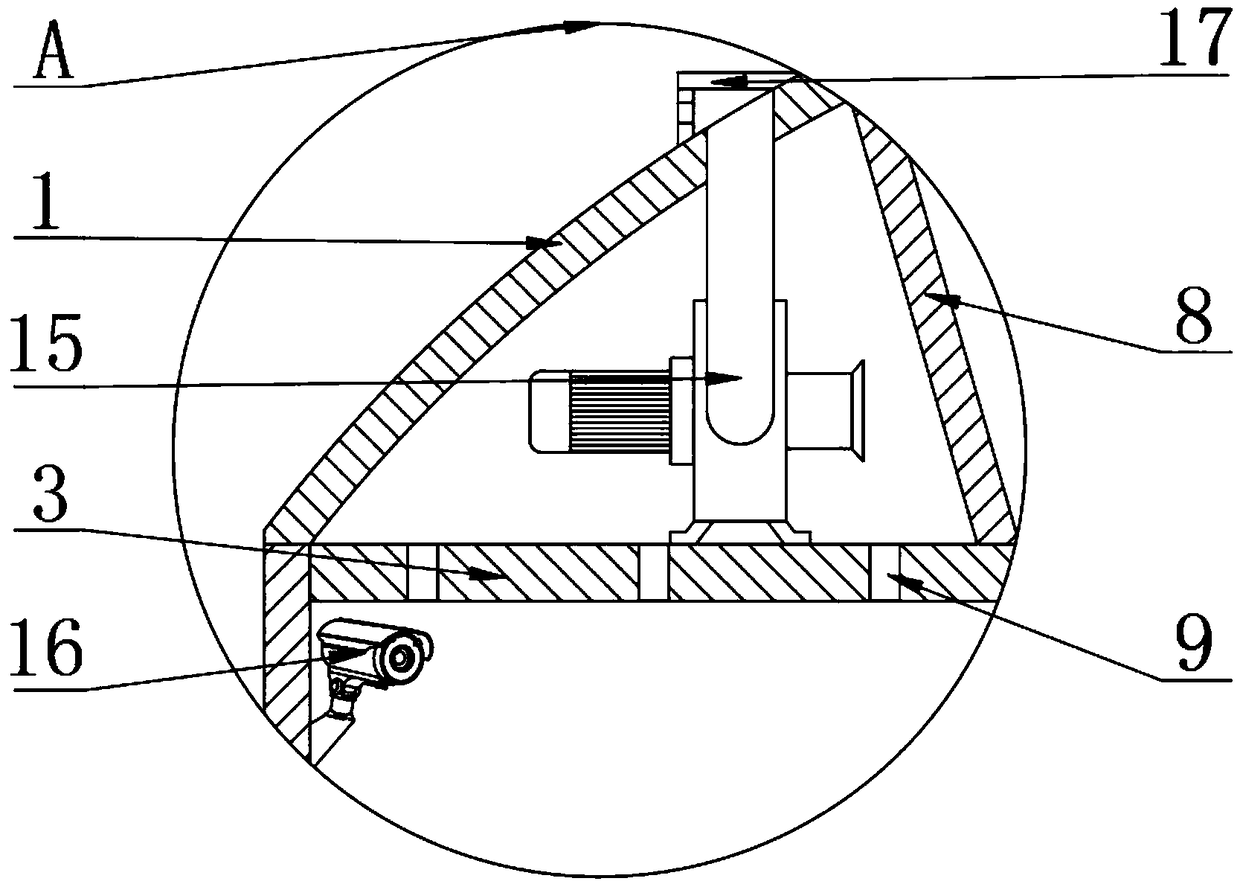

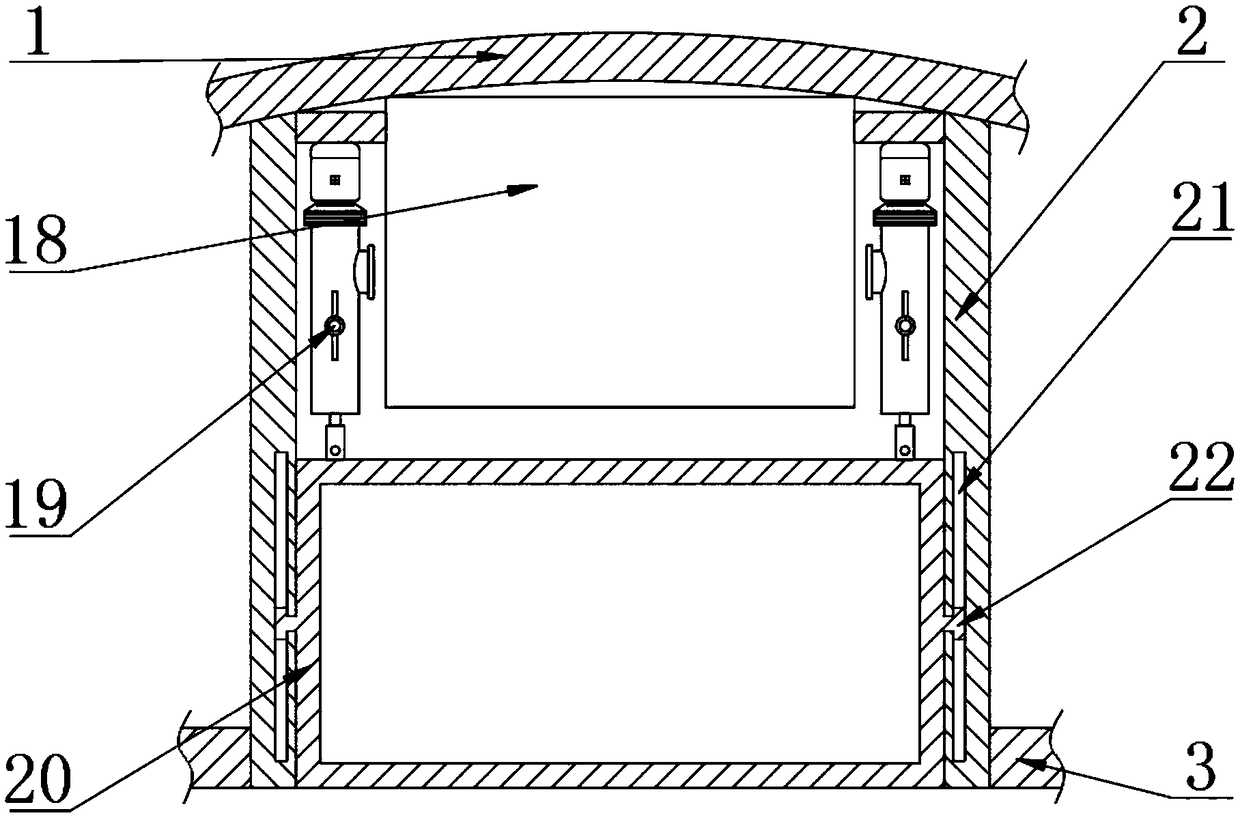

Multifunctional computer room

InactiveCN108868220AEasy to installEasy to disassemble and repairRoof covering using slabs/sheetsDucting arrangementsFixed frameElectro hydraulic

The invention discloses a multifunctional computer room, which comprises a roof, a mounting shell, a ceiling, a supporting wall body, a floor, a wiring cavity, a solar panel, a support rod, a ventilation hole, a ventilation pipe, a mounting hole, a first ventilation box body, a ground wire row, a second ventilation box body and a first induced draft fan, a camera, a rain shield frame, a storage battery, an electro-hydraulic push rod, an air conditioner installation frame, a sliding groove, sliding blocks, a wall body base layer, an insulating layer, a noise reduction layer, a mounting strip, athrough hole, a fan blade, a fixing frame, a filtering layer, a second induced draft fan and a supporting plate, the output end of the electro-hydraulic push rod is welded and fixed to the two sidesof the top of the air conditioner installation frame, the two sides of the air conditioner installation frame are provided with the sliding blocks, the sliding blocks are in sliding connection with the sliding groove, the sliding groove is arranged in the inner wall of the two sides of the installation shell, the computer room is environment-friendly and energy-saving, and the heat-insulating andnoise-reducing effects are good, moreover, the installation, disassembly and maintenance of the air conditioner are facilitated, the abrasion sound of the floor is reduced, the service life is prolonged, and the anti-static effect is remarkable.

Owner:佛山途睿网络科技有限公司

A kind of erbium-reinforced magnesium-lithium alloy and preparation method thereof

The invention provides erbium strengthened magnesium-lithium alloy and a preparation method thereof. The magnesium-lithium alloy prepared through the following method comprises, by mass, 5%-11% of Li, 0.5%-10% of Er, not more than 5% of Al and the balance magnesium and inevitable impurity elements. The preparation method comprises the steps that (1) smelting is conducted under the condition of vacuum or protective atmosphere after component proportioning is designed according to the alloy elements, and then an alloy ingot is poured; (2) homogenization treatment is conducted at the temperature of 200 DEG C-500 DEG C, and the homogenization treatment time is 0.5-10 h; (3) multi-pass rolling is conducted at the temperature of 250 DEG C-400 DEG C, and the total reduction rate is 20%-90%; and (4) two times of aging treatment can also be conducted before and after rolling. According to the erbium strengthened magnesium-lithium alloy and the preparation method thereof, the alloy components, the two times of aging treatment temperature, the treatment time, the cooling process, the hot rolling temperature, the hot rolling passes and the deformation parameters are controlled, so that the grain size of the erbium strengthened magnesium-lithium alloy is refined, and the mechanical property is improved.

Owner:HARBIN ENG UNIV

Quality control method of amygdalin in children lung heat cough and asthma granules

ActiveCN113834895ALess sample volumeEffective content controlComponent separationThin layer chromatographicAmygdalin

The invention provides a quality control method of amygdalin in children lung heat cough and asthma granules. A thin-layer chromatography identification method has the advantages of small sample application amount, good separation effect, clear spots, moderate specific shift value and good reproducibility. Quantitative analysis is carried out on the amygdalin component in the infantile lung-heat cough and asthma granules through content determination, it is verified that the content of the amygdalin in the infantile lung-heat cough and asthma granules can be accurately and efficiently detected through content determination chromatographic conditions, and through combination of a thin-layer chromatography identification method and content, the content of amygdalin in the children lung heat cough and asthma granules can be effectively controlled, and the medication safety of the children lung heat cough and asthma granules is ensured.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

High-cleanliness low-carbon steel converter molten steel direct-up steel casting method

PendingCN113621871AImprove cleanlinessReduce contentManufacturing convertersSteelmakingLiquid carbon

The invention belongs to the technical field of converter steelmaking, and particularly relates to a high-cleanliness low-carbon steel converter molten steel direct-up steel casting method. The method comprises the following steps: the proportion of molten iron and scrap steel is adjusted; the silicon component of the molten iron is finely adjusted before converter smelting, so that the content of Si reaches 0.50 wt%; the oxygen supply flow is 27000 to 29000 m < 3 > / h, and the oxygen pressure is 0.80 to 1.00 Mpa; liquid carbon-based metal is combined with double vent plugs for bottom blowing deoxidation; after tapping is finished, hot-state refining slag is added into a steel ladle for slagging; after the hot-state refining slag is added into a converter, all steel ladle vent plugs are opened; and after blowing and stirring of the converter are finished, steel casting is conducted through direct-up continuous casting. Compared with a traditional three-step smelting technology of refining treatment, the refining treatment period is eliminated, the cost is greatly reduced, the content of inclusions is effectively controlled, the cleanliness of molten steel is greatly improved, and the quality stability of low-carbon steel direct-up steel casting is improved.

Owner:TIANJIN TIANGANG UNITED SPECIAL STEEL CO LTD

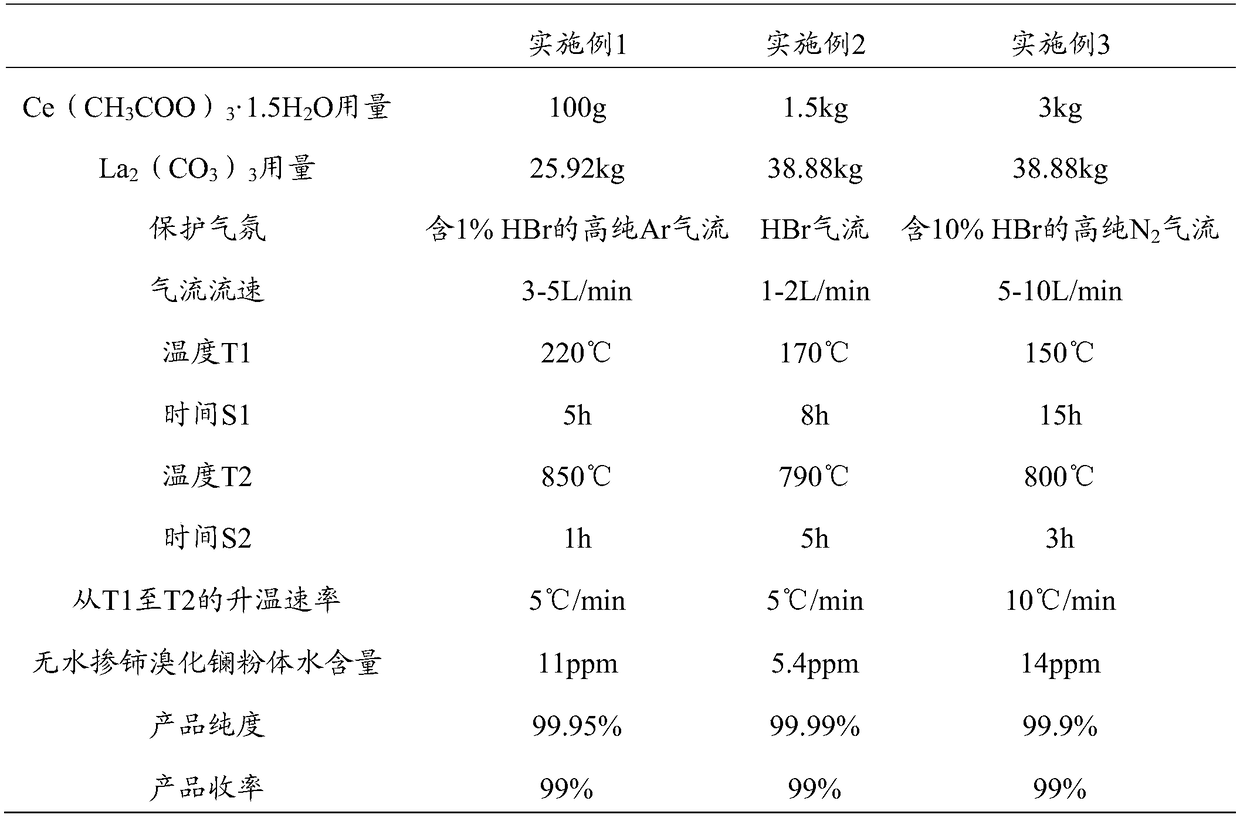

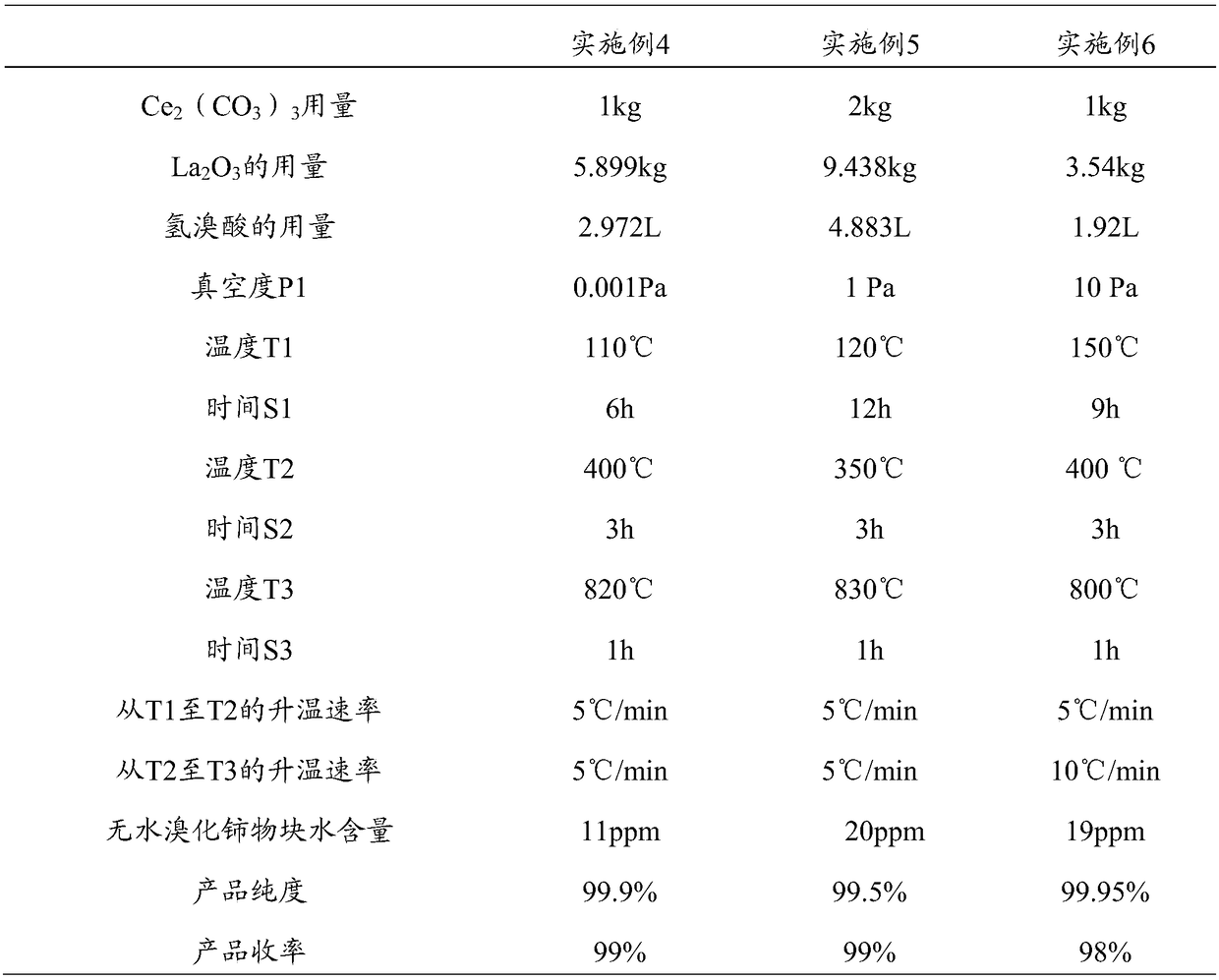

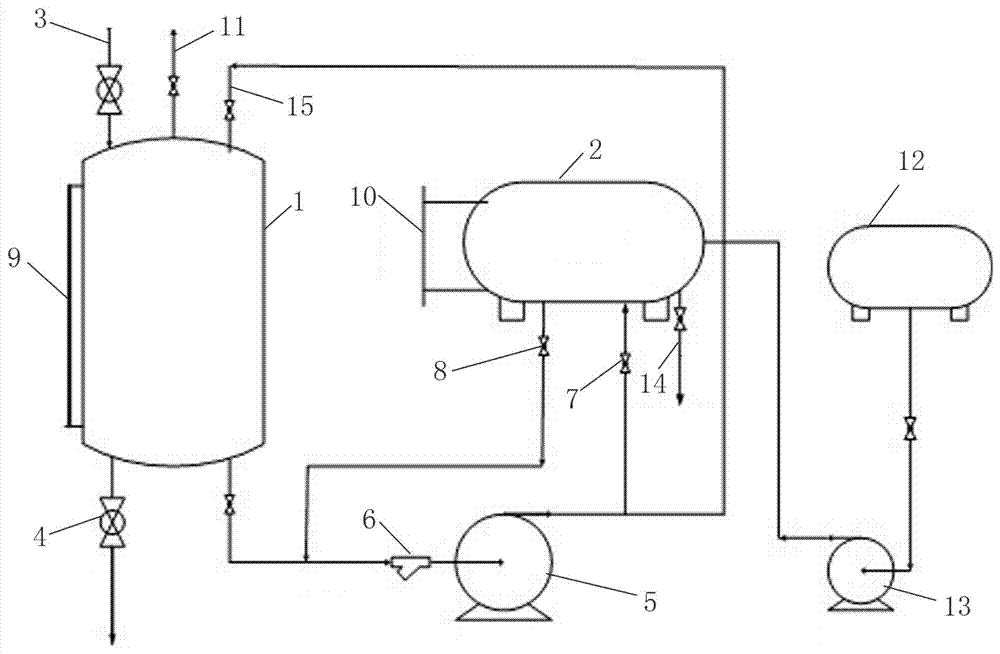

Anhydrous cerium-doped lanthanum bromide and preparation method thereof

InactiveCN109502628ARealize mass productionWell mixedRare earth metal halidesLanthanum fluorideScintillation crystals

The invention provides a preparation method of anhydrous cerium-doped lanthanum bromide. The preparation method comprises the following steps: (1) enabling a cerium source to react with a lanthanum source under the existence of bromide ions; (2) melting and cooling a reaction product obtained in the step (1) to obtain the anhydrous cerium-doped lanthanum bromide, wherein the step (1) and the step(2) are performed in a protective atmosphere or under vacuum. The invention provides the anhydrous cerium-doped lanthanum bromide of which the moisture content is lower than 100 ppm. The preparation method provided by the invention effectively solves the problem of non-uniform mixing of a solid and a solid; the operation steps are simple, reaction conditions are easy to reach, and the production cost is low. The anhydrous cerium-doped lanthanum bromide provided by the invention can be directly used for the growth of a cerium-doped lanthanum bromide scintillation crystal, obtained crystal cerium is uniformly distributed, and the performance is better.

Owner:厦门中烁光电科技有限公司 +1

Oxidation-resisting wear-resisting alloy steel for temperature sensor and preparation method thereof

The invention discloses an oxidation-resisting wear-resisting alloy steel for a temperature sensor. The oxidation-resisting wear-resisting alloy steel for the temperature sensor comprises, by weight, 0.1%-0.2% of C; not larger than 0.55% of Si, 1.0%-1.6% of Mn, 18.2%-24.2% of Cr, not larger than 0.04% of P, not larger than 0.04% of S, 0.02%-0.15% of V, 0.015%-0.06% of Nb, 0.01%-0.03% of Al, 0.01%-0.03% of Ti, 0.2%-0.4% of Mo, 0.1%-0.3% of Bi, 0.2%-0.6% of Y, 14%-15% of Ni, 0.02%-0.08% of rare earth and the balance Fe and inevitable impurities. The invention further discloses a preparation method of the oxidation-resisting wear-resisting alloy steel for the temperature sensor. According to the oxidation-resisting wear-resisting alloy steel for the temperature sensor and the preparation method of the oxidation-resisting wear-resisting alloy steel for the temperature sensor, through reasonable selection of components, the prepared alloy steel for the temperature sensor has excellent oxidation resistance and wear resistance.

Owner:ANHUI RUIXIN AUTOMATION INSTR

Treatment agent for removing harmful metal elements on catalyst surface and removal method thereof

ActiveCN104971785BEfficient removalEffective content controlCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsCatalytic reformingAcetic acid

The invention relates to a treatment agent of removing harmful metal elements from the surface of a catalyst, wherein the treatment agent includes following components, by mass, 0.1-10% of disodium ethylene diamine tetraacetate, 0.1-15% of sulphamic acid or / and sulfosalicylic acid, 0.005-0.1% of aspartic acid or / and polyepoxysuccinic acid, 0.01-0.5% of a surfactant and the balanced being water. The invention also relates to a method of removing the harmful metal elements from the surface of the catalyst with the treatment agent. The method is simple and available. The catalyst can be soaked completely in the treatment agent, so that the harmful metal elements in the catalyst are directly subjected to a chemical reaction with the treatment agent in liquid phase, wherein generated substances are dissolved in the treatment agent, so that the harmful metal elements can be high-effectively removed under the situation of not changing the content and distribution of the active elements on the surface of the catalyst, thereby effectively controlling the content of the harmful metal elements on the surface of the catalyst for maintaining the activity and the catalytic reforming performance of the catalyst.

Owner:SINOPEC YANGZI PETROCHEM +1

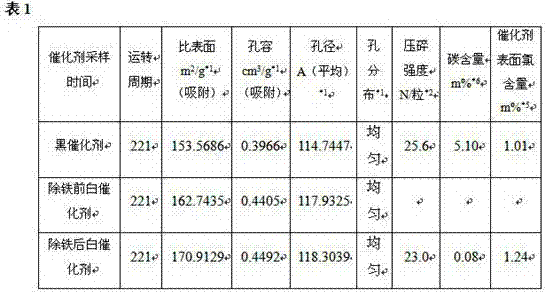

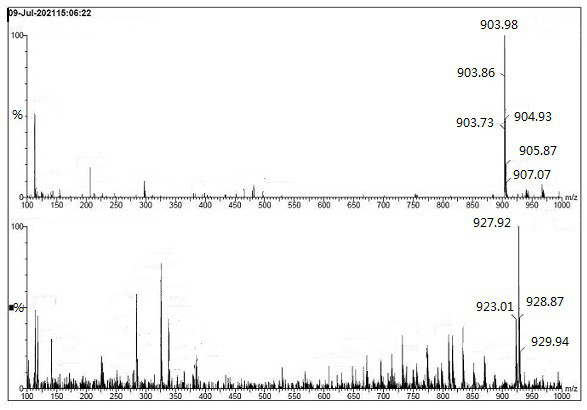

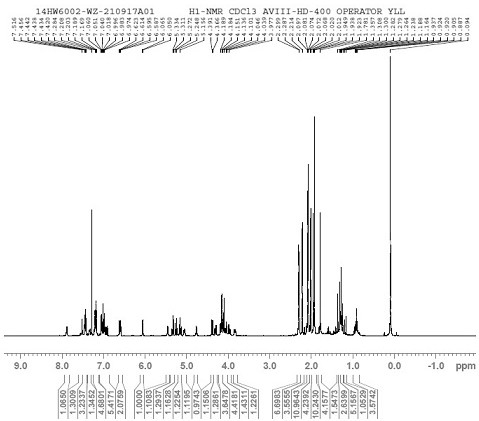

Canagliflozin impurity, preparation and removal method

ActiveCN114181270BEffective content controlSugar derivativesOrganic chemistry methodsPhysical chemistryCanagliflozin

The invention belongs to the technical field of medicinal chemistry, and specifically relates to canagliflozin impurities, preparation and removal methods. The canagliflozin impurities disclosed in the present invention are produced during the production process of canagliflozin, and the disclosed impurities can be canagliflozin The quality control of net intermediates provides qualified impurity reference substances. The impurity removal method provided by the present invention can effectively improve the purity of the canagliflozin intermediate, and the purity of the intermediate can reach 99.91%, thereby improving the purity of the canagliflozin product. The canagliflozin impurity reference substance can be developed for the canagliflozin process The monitoring of this impurity in the drug provides an important reference basis and improves the quality monitoring level of canagliflozin.

Owner:南京安杰新生物医药有限公司

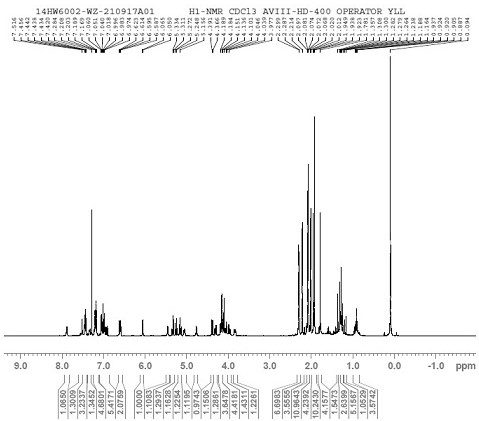

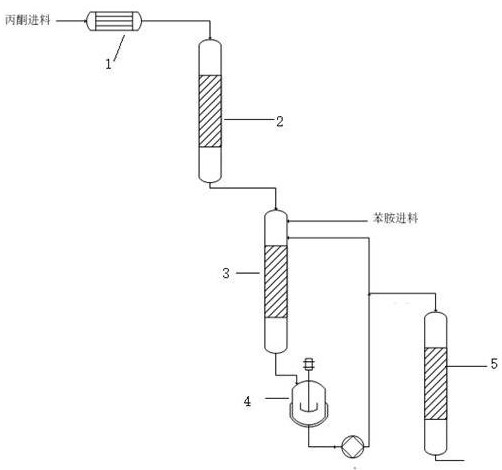

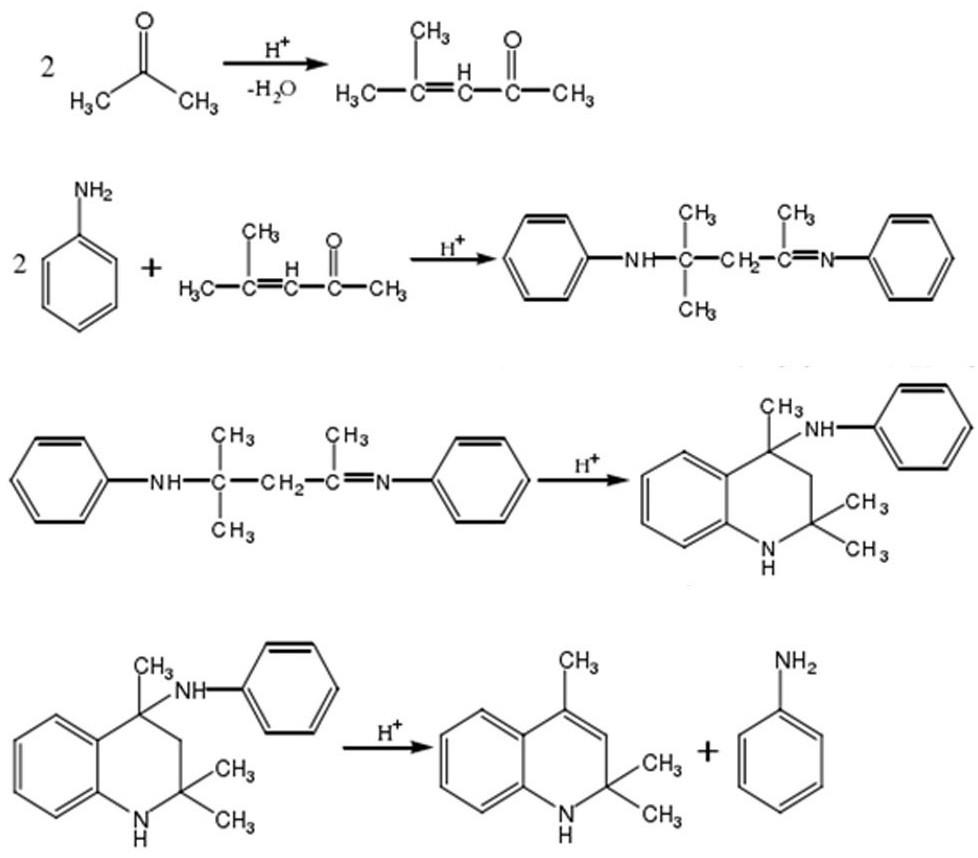

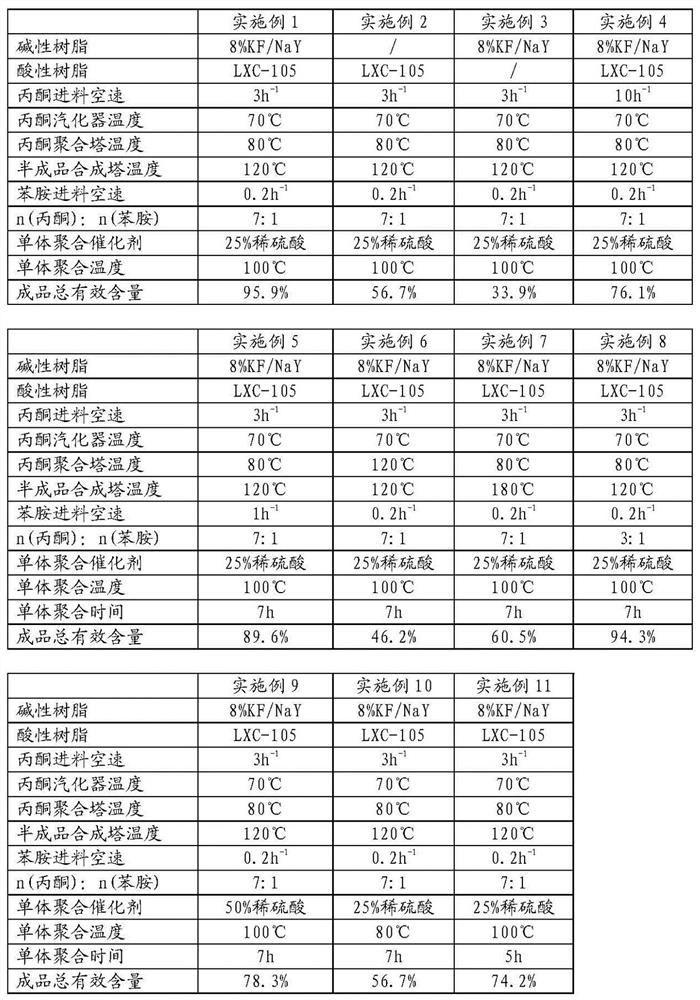

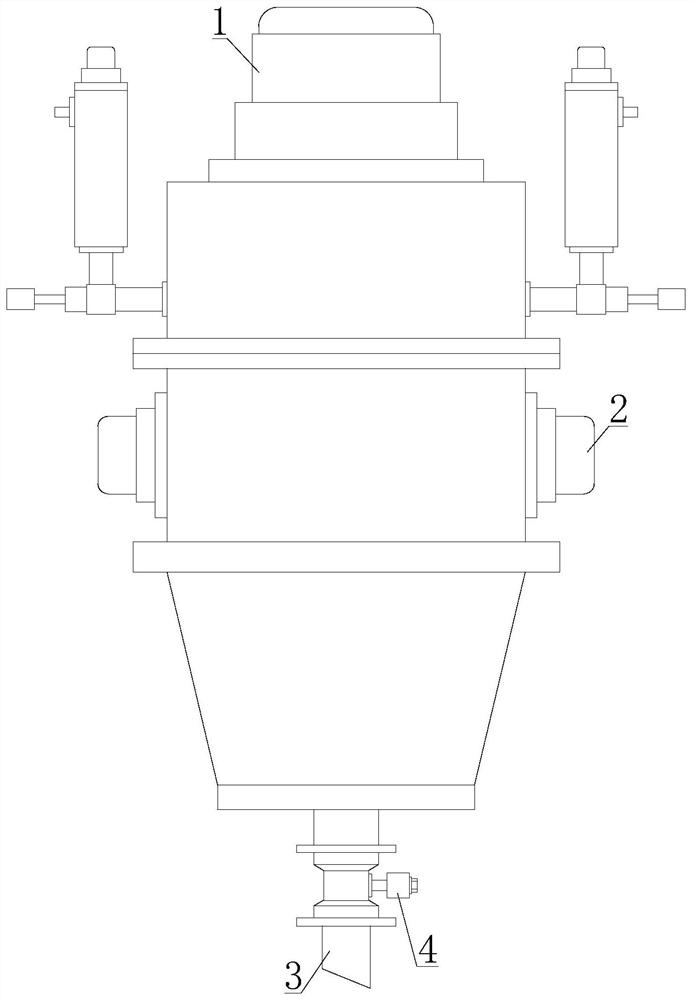

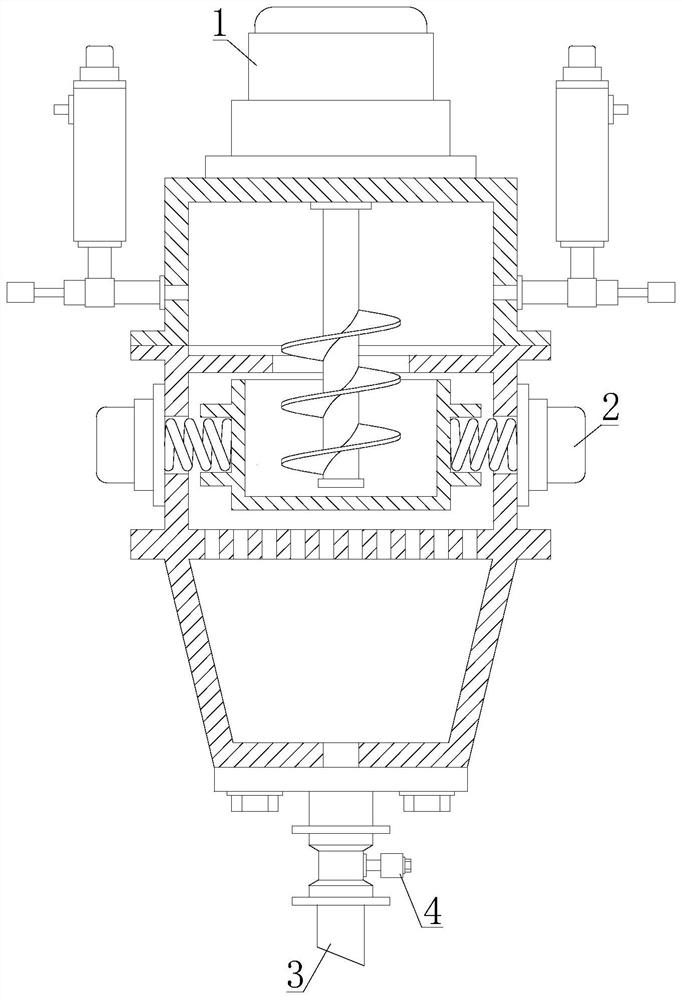

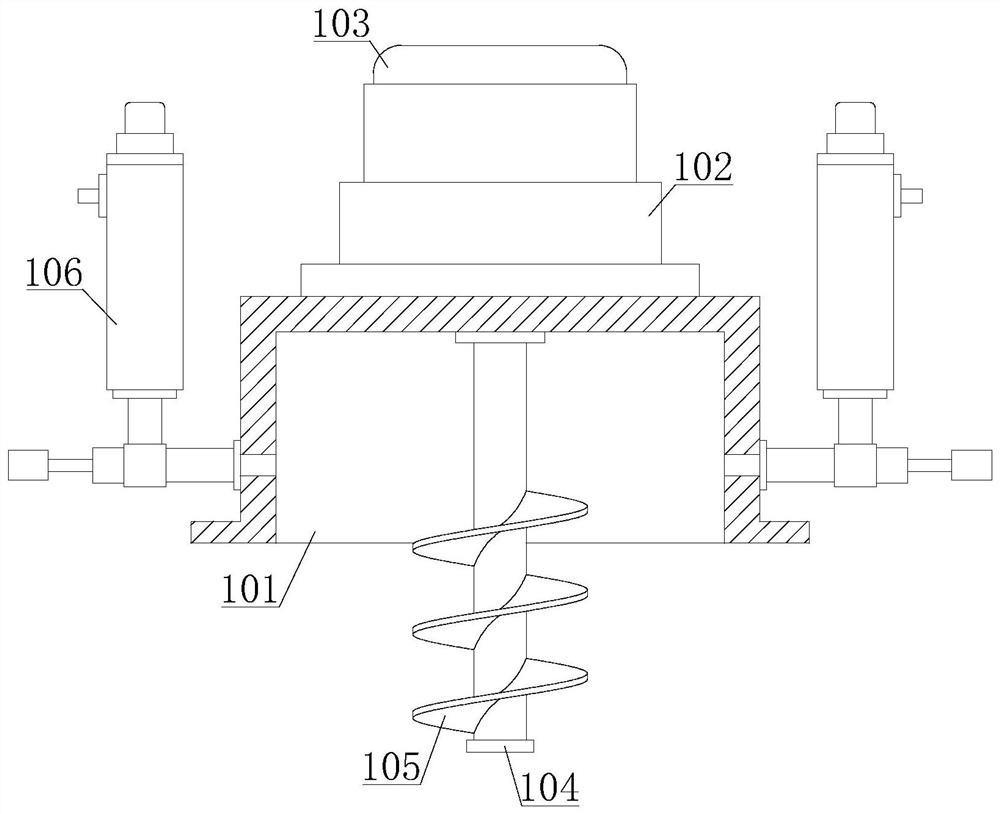

Preparation device and preparation method of rubber antioxidant TMQ

ActiveCN114773264AControl spawn rateEffective content controlOrganic chemistryPolymer scienceEngineering

The invention belongs to the field of anti-aging agents, and particularly relates to a preparation device and a preparation method of a rubber anti-aging agent TMQ. The preparation device comprises an acetone preheater, an acetone polymerization tower, a semi-finished product synthesis tower, a semi-finished product receiving kettle and a reaction kettle which are sequentially connected, the semi-finished product synthesis tower is provided with an aniline feeding hole; alkaline resin is arranged in the acetone polymerization tower, and acidic resin is arranged in the semi-finished product synthesis tower; the acetone preheater, the acetone polymerization tower, the semi-finished product synthesis tower, the semi-finished product receiving kettle and the reaction kettle are all provided with heaters. The catalyst for controlling acetone polymerization and corresponding control steps are developed for the first time, the acetone polymerization is controlled in a dimer-based range, and then under the action of a second catalyst, the acetone and aniline are subjected to a polymerization reaction to generate a TMQ monomer.

Owner:KEMAI CHEM

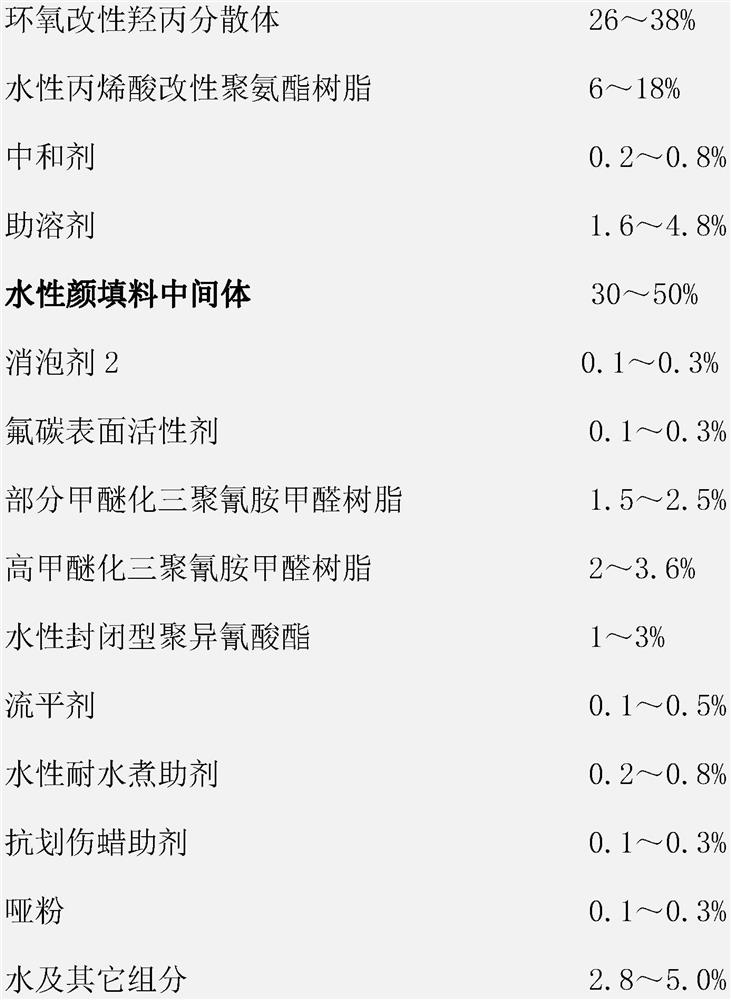

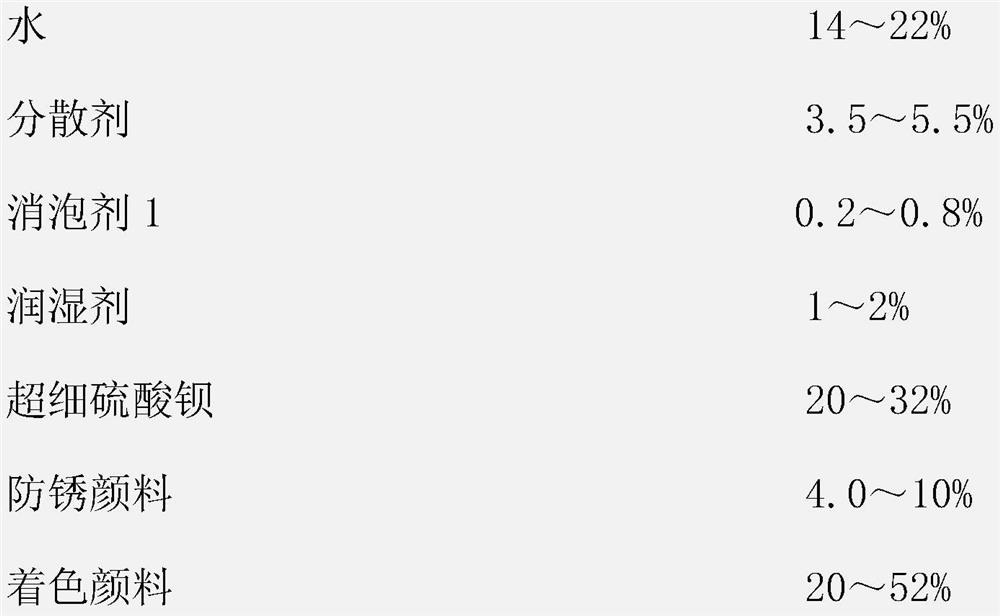

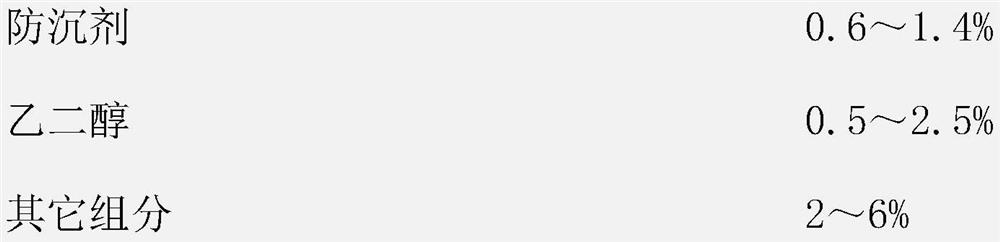

High-resistance water-based metal matte stoving varnish for computer case and preparation method of high-resistance water-based metal matte stoving varnish

PendingCN114806299AEffective content controlHigh hardnessPolyurea/polyurethane coatingsPolymer scienceActive agent

The invention belongs to the technical field of water-based paint, and particularly discloses high-resistance water-based metal matte stoving varnish for a computer case and a preparation method of the high-resistance water-based metal matte stoving varnish. The stoving varnish comprises the following components by weight: 26-38% of an epoxy modified hydroxypropyl dispersion; 6 to 18 percent of water-based acrylic acid modified polyurethane resin; 0.2 to 0.8 percent of a neutralizing agent; 1.6%-4.8% of a cosolvent; 30-50% of a water-based pigment and filler intermediate; 0.1 to 0.3% of a defoaming agent 2; 0.1%-0.3% of a fluorocarbon surfactant; 1.5 to 2.5% of a partially methylated melamine formaldehyde resin; 2 to 3.6 percent of high methylated melamine formaldehyde resin; 1%-3% of water-based blocked polyisocyanate; 0.1 to 0.5% of a leveling agent; 0.2%-0.8% of a water-based boiling-resistant auxiliary agent; 0.1 to 0.3% of a scratch-resistant wax auxiliary agent; 0.1 to 0.3 percent of matt powder; 2.8 to 5.0 percent of water and other components. The product provided by the invention can comprehensively meet the performance indexes of a baking varnish film of a computer case in the aspects of hot water resistance, 95% ethanol resistance, coffee resistance, cola resistance, cleaning agent resistance, 1% glacial acetic acid resistance, edible oil and the like.

Owner:中山蓝海洋水性涂料有限公司

Canagliflozin impurities, and preparation and removal methods thereof

ActiveCN114181270AEffective content controlSugar derivativesOrganic chemistry methodsChemical physicsPhysical chemistry

The invention belongs to the technical field of medicinal chemistry, and particularly relates to a canagliflozin impurity and a preparation and removal method thereof, the canagliflozin impurity disclosed by the invention is generated in a canagliflozin production process, and the disclosed impurity can provide a qualified impurity reference substance for quality control of a canagliflozin intermediate. According to the impurity removal method, the purity of the canagliflozin intermediate can be effectively improved, the purity of the intermediate can reach 99.91%, then the purity of the canagliflozin product is improved, a canagliflozin impurity reference substance can provide an important reference basis for monitoring of the impurity in research and development of a canagliflozin process, and the canagliflozin quality monitoring level is improved.

Owner:南京安杰新生物医药有限公司

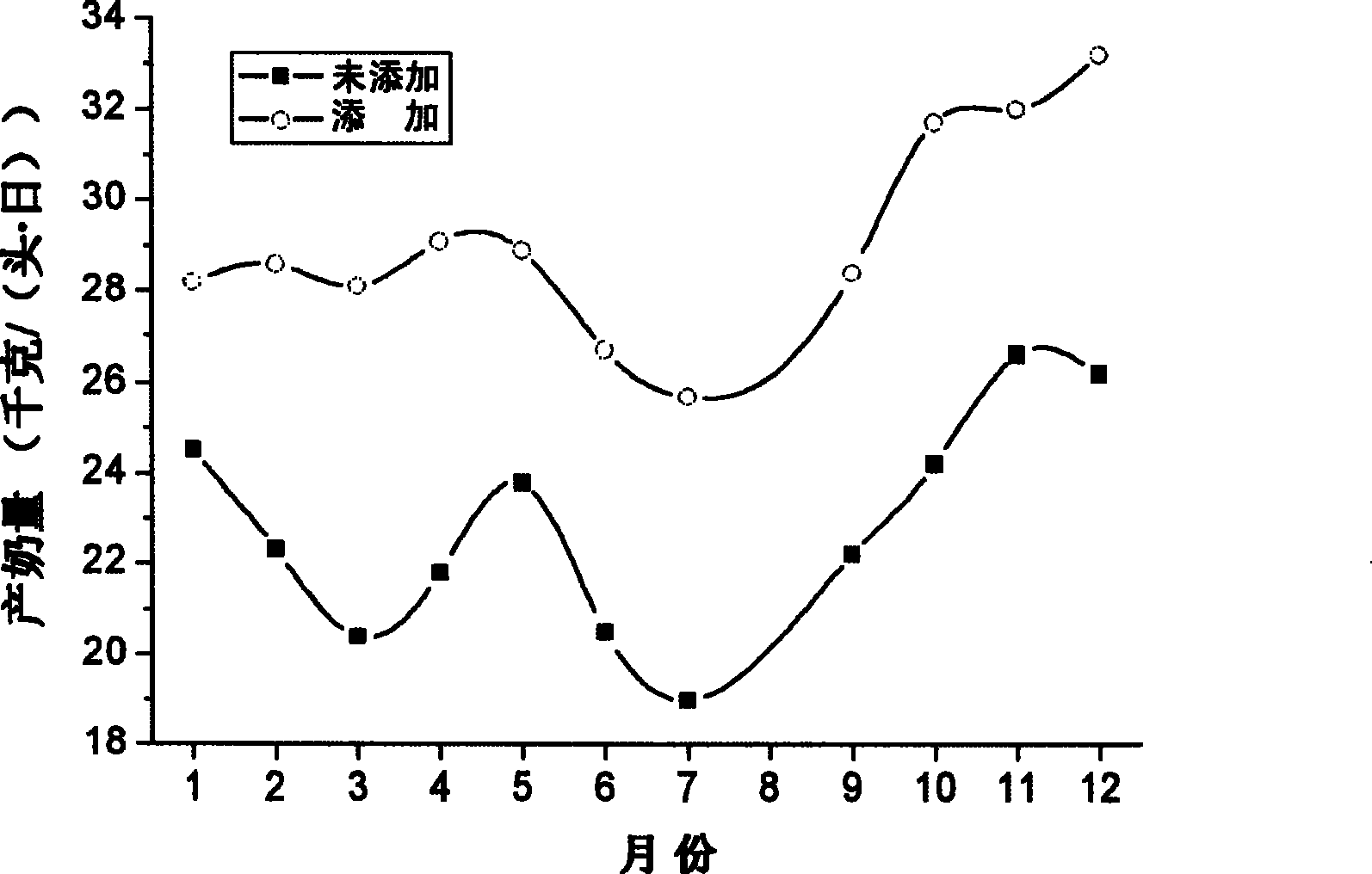

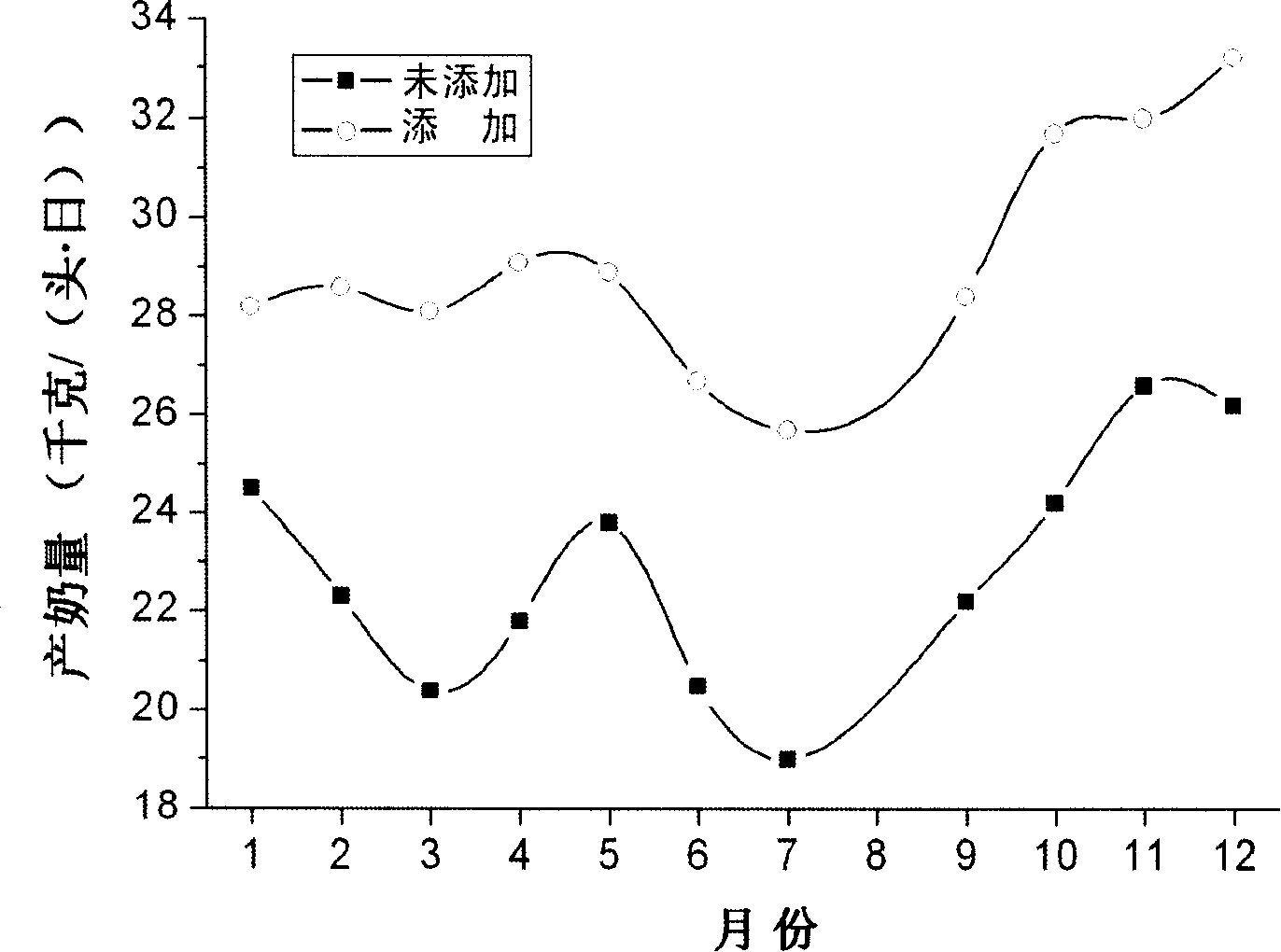

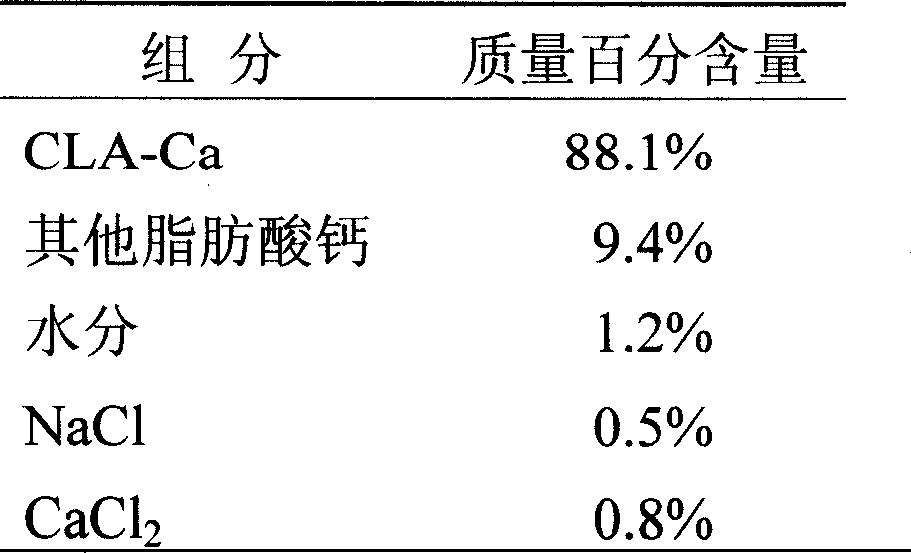

Composition containing calcium conjugated linoleate and its preparation method

ActiveCN101032278BIncrease contentEffective content controlOrganic active ingredientsAnimal feeding stuffVegetable oilIsomerization

The present invention discloses one kind of composition containing calcium conjugate linoleate for increasing the milk output of milk cow and its preparation process. The composition is prepared with vegetable oil as material, and through ester exchange reaction, molecular distillation, saponification, isomerization and metathetical reaction. It consists of alphatic calcium, water and impurity salt; and the alphatic calcium includes calcium conjugate linoleate accounting for 82-90 wt% of the composition, calcium palmitate, calcium stearate, calcium oleate and calcium linoleate accounting for 8-15 wt% of the composition. It has high calcium conjugate linoleate content, controllable content of other kinds of alphatic calcium and excellent physical character. It is used in raising milk cow to raise milk output obviously.

Owner:INNOBIO CORP LTD

Preparation method of catalyst for synthesizing piperazine through monoethanolamine catalytic amination one-step method

ActiveCN103433050BSimple manufacturing processGuaranteed selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingPiperazine

The invention discloses a preparation method of a catalyst for synthesizing piperazine through a monoethanolamine catalytic amination one-step method. The catalyst is spherical particles prepared by taking a mixture containing gamma-Al2O3 and theta-Al2O3 as a matrix, wherein the specific surface area of the catalyst is 200-300 m<2> / g; the pore volume is 0.45-0.65 cm<3> / g; the particle size is 1.0-3.0 mm. The catalyst mainly comprises the following components: 0-15% of Ni, 0-10% of Co, 0-5% of Mo, 0-10% of Fe, and 0-5% of La. The preparation method of the catalyst comprises the following steps: dipping a carrier for 4.0-12.0 h, then performing dehydration, spraying and performing dehydration, drying, baking, and activating the substance to prepare the spherical particle-like catalyst. The preparation method has the advantages that the solid catalyst for synthesizing piperazine through the monoethanolamine catalytic amination one-step method is prepared; the preparation method of the catalyst adopts a dipping and spraying combined technology, so that the method is simple and convenient to operate; the catalytic medium is free from addition of noble metal, so that the preparation cost of the catalyst is obviously reduced. When the catalyst is used for synthesizing piperazine through the monoethanolamine catalytic amination one-step method, the preparation method has the characteristics of high reaction selectivity and high reaction yield.

Owner:ZHEJIANG LYUKEAN CHEM

Mixing and blending device for water-borne wood paint production and implementation method of mixing and blending device

InactiveCN113198358AEffective content controlQuality assuranceShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringElectric control

The invention discloses a mixing and blending device for water-borne wood paint production and an implementation method thereof. The mixing and blending device comprises a blending assembly, a mixing assembly and an electric control valve, materials stirred and blended through blending blades in a stirring material pipe are fed into a mixing shell in the mixing assembly through a material pushing head driven by a material pushing rod. a wood paint semi-finished product flows into a mixing screening groove through a through hole after being guided by a guide plate in the mixing shell, the ingredients and the wood paint semi-finished product with different contents are stirred and mixed uniformly by the stirring blades in the mixing screening groove, and a vibration pump drives the mixing screening groove to vibrate through tvibration springs, so that the mixture is screened out from wood paint screening holes in the bottom of the mixing screening groove. And after being permeated by permeation holes in a permeation plate, the mixture is stored at the bottom of the mixing shell, an operator can open theelectric control valve and collect the blended product through a discharge port, the content of various added components can be effectively controlled, and meanwhile, generated precipitates can be effectively removed in the blending process so as to ensure the quality of the product.

Owner:安徽名士达新材料有限公司

A kind of preparation method of bromfenac sodium sesquihydrate

ActiveCN104151182BImprove stabilityReduce usageOrganic compound preparationAmino-carboxyl compound preparationAlcoholAnti solvent

The invention aims at providing a preparation method of bromfenac sodium sesquihydrate. The preparation method comprises the following steps: (1) adding bromfenac sodium and an antioxidant into a mixed solvent of water and an organic alcohol, heating, dissolving and adding a pH adjustor to adjust the pH to 7.0-10.5; (2) adding an anti-solvent into a solution obtained in the step (1), cooling the solution to 30 DEG C to 35 DEG C, adding bromfenac sodium monohydrate, bromfenac sodium sesquihydrate or a mixture thereof as a seed crystal, and stirring; and (3) cooling, crystallizing, collecting crystals and drying to obtain the bromfenac sodium sesquihydrate. The preparation method avoids use of ether agents and is mild in reaction condition and good in environmental benefit. The prepared bromfenac sodium sesquihydrate is high in purity.

Owner:GUANGDONG ZHONGSHENG PHARMA

Preparation method of low dysprosium corrosion-resistant sintered NdFeB

ActiveCN103456452BModerate diffusionReduce the temperatureVacuum evaporation coatingSputtering coatingSputteringDysprosium

Owner:NANJING UNIV OF SCI & TECH +1

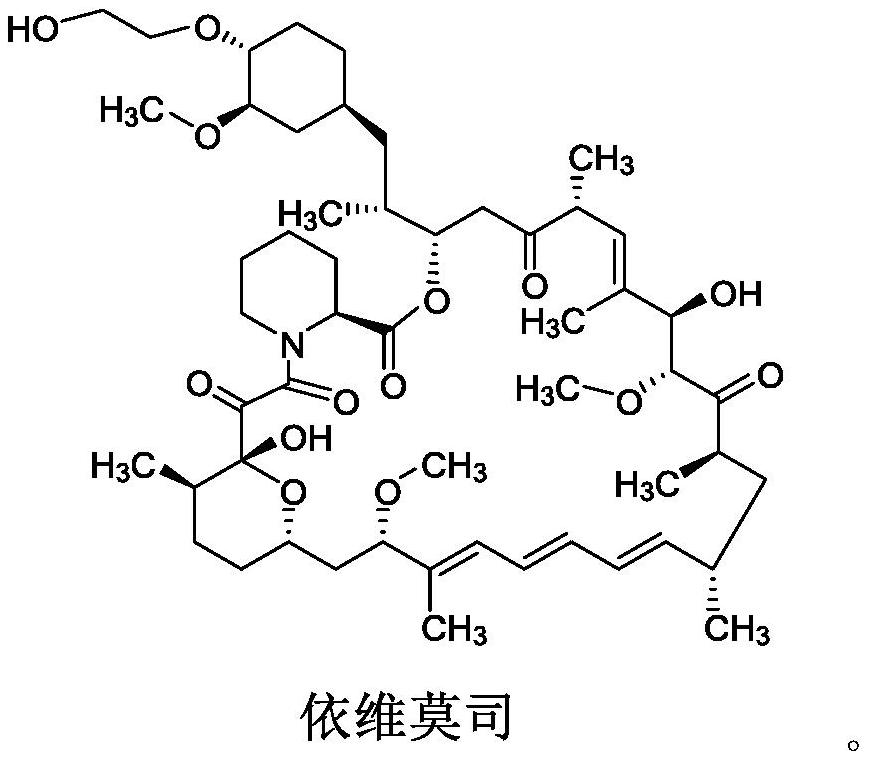

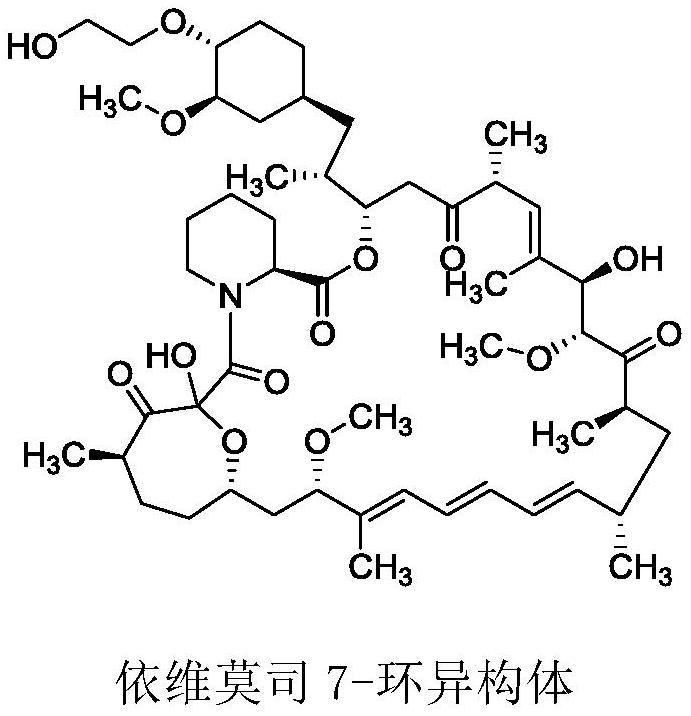

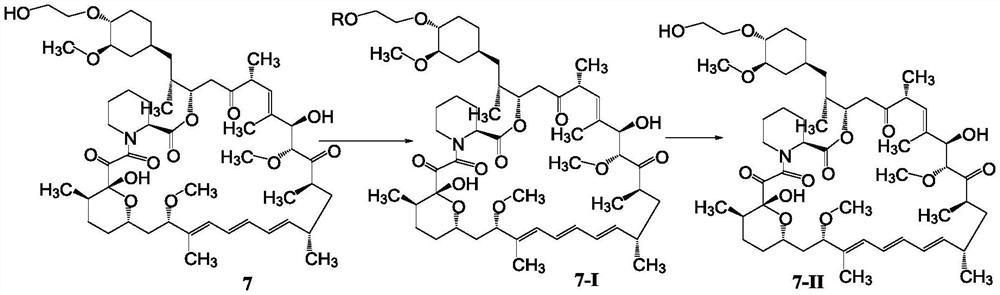

A kind of purification method of everolimus

ActiveCN109206441BReduce contentEffective content controlGroup 4/14 element organic compoundsEverolimusFluid phase

The present invention provides a purification method of everolimus. Everolimus is derivatized, separated, and then hydrolyzed, and the content of impurity rapamycin in the treated everolimus is greatly reduced. Further, the product with higher purity can be obtained at a higher yield through one-time preparation of liquid phase purification, thereby reducing the industrial cost of the purification step; the application further provides a preparation method of everolimus, which has a high yield and is easy to operate. Simple and suitable for industrial production.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com