Preparation method of catalyst for synthesizing piperazine through monoethanolamine catalytic amination one-step method

An ethanolamine-catalyzed amine and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as high temperature and high pressure, achieve temperature and pressure reduction, The economic benefits are obvious and the preparation cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

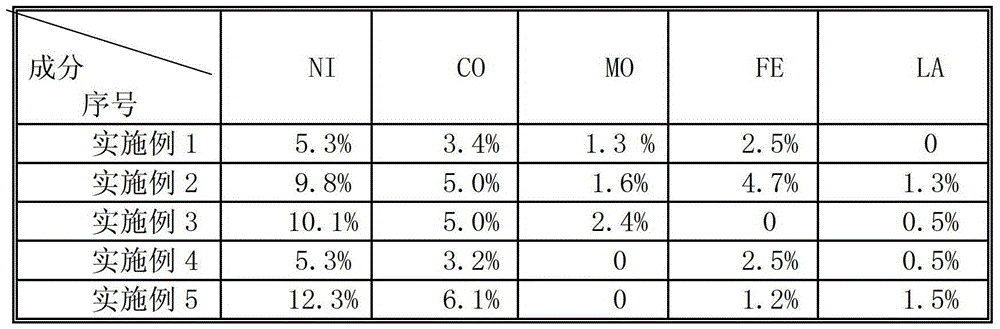

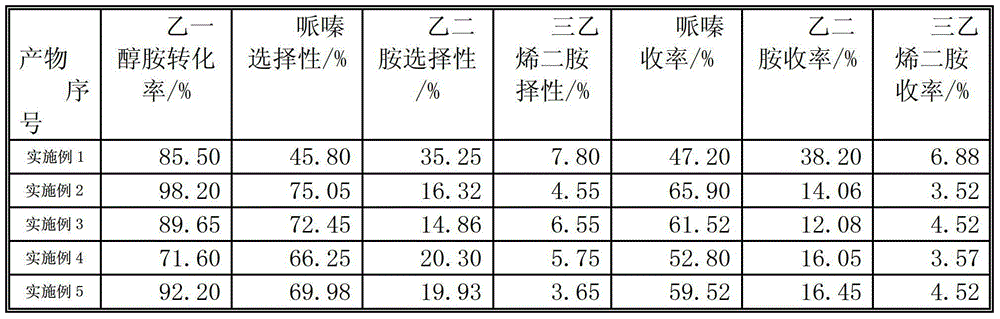

Embodiment 1

[0016] The preparation method of the monoethanolamine-catalyzed amination one-step method for the synthesis of piperazine catalyst in this example includes the following steps: 1) Preparation of the carrier: use γ-Al 2 o 3 and θ-Al 2 o 3 The mixture is the carrier; it is made with a specific surface area of 250m 2 / g, the pore volume is 0.55cm 3 / g, a carrier of spherical particles with a particle size of 2.0 mm.

[0017] 2) Weigh Ni (NO 3 ) 2 .6H 2 O29.1g (0.1mol), Co (NO 3 ) 2 .6H 2 O17.50g (0.06mol), MO (NO 3 ) 3 .5H 2 O6.65g (0.015mol), Fe (NO 3 ) 3 .9H 2 O20.2g (0.05mol), the concentration of its element corresponding salt is: Ni is 0.22mol / L, Co is 0.13mol / L, Mo is 0.033mol / L, Fe is 0.11mol / L. Add deionized water and fully stir and dissolve in a water bath at 60±2°C to form a 450ml solution.

[0018] 3) Take 300ml of the prepared solution in step 2) and weigh 100g of γ-Al 2 o 3 and θ-Al 2 o 3 The carrier is placed therein and soaked for 6.0 hours. ...

Embodiment 2

[0021] The preparation method of the monoethanolamine-catalyzed amination one-step method for the synthesis of piperazine catalyst in this example includes the following steps: 1) Preparation of the carrier: use γ-Al 2 o 3 and θ-Al 2 o 3 The mixture is the carrier; it is made with a specific surface area of 200m 2 / g, the pore volume is 0.45cm 3 / g, a carrier of spherical particles with a particle size of 1.0 mm.

[0022] 2) Weigh Ni (NO 3 ) 2 .6H 2 O58.2g (0.2mol), Co (NO 3 ) 2 .6H 2 O29.0g (0.10mol), MO (NO 3 ) 3 .5H 2 O8.86g (0.02mol), Fe (NO 3 ) 3 .9H 2 O40.4g (0.10mol), La (NO 3 ) 3 .6H 2O8.66g (0.02mol), the concentration of its element corresponding salt is: Ni is 0.44mol / L, Co is 0.22mol / L, Mo is 0.044mol / L, Fe is 0.22mol / L, La is 0.44mol / L L. Add deionized water and fully stir and dissolve in a water bath at 60±2°C to form a 450ml solution.

[0023] 3) Take 300ml of prepared solution and weigh 100g of γ-Al 2 o 3 and θ-Al 2 o 3 The carrier wa...

Embodiment 3

[0026] The preparation method of the monoethanolamine-catalyzed amination one-step method for the synthesis of piperazine catalyst in this example includes the following steps: 1) Preparation of the carrier: use γ-Al 2 o 3 and θ-Al 2 o 3 The mixture is the carrier; it is made with a specific surface area of 300m 2 / g, the pore volume is 0.65cm 3 / g, a carrier of spherical particles with a particle size of 3.0 mm.

[0027] 2) Weigh Ni (NO 3 ) 2 .6H 2 O58.2g (0.2mol), Co (NO 3 ) 2 .6H 2 O29.0g (0.10mol), MO (NO 3 ) 3 .5H 2 O13.30g (0.03mol), La (NO 3 ) 3 .6H 2 O4.4g (0.01mol), the concentration of the corresponding salt of its element is: Ni is 0.44mol / L, Co is 0.22mol / L, Mo is 0.066mol / L, La is 0.022mol / L. Add deionized water and fully stir and dissolve in a water bath at 60±2°C to form a 450ml solution.

[0028] 3) Take 300ml of prepared solution and weigh 100g of γ-Al 2 o 3 and θ-Al 2 o 3 The carrier was placed therein and soaked for 12.0 hours.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com